Building a staircase for a summer residence with your own hands is a difficult, but quite feasible event. To complete it, you need to choose the optimal design, draw up a competent project, choose the right material and assemble the structure in accordance with the instructions. In the design process, it is necessary to take into account many nuances in order for the structure to be beautiful, convenient, reliable and safe.

Constructive types of stairs

Country staircases vary in design, shape, layout and function. The choice is made based on the analysis of these criteria, the physiological characteristics of the residents.

The most popular in the private sector are the following designs:

- Marching. They represent one or more spans located along the wall of the building. The number of marches is determined by the height of the structure and the minimum steepness that the weakest inhabitant of the house or guest can handle. An odd number of steps should be made on one span. Optimally 7 and 9.

- Screw. They consist of a vertical stand, on which support panels are fixed in a circle with a narrow side. The structure takes up little space, but is not suitable for carrying bulky items. In addition, this type is characterized by an increased steepness, which makes it difficult for children and the elderly to move. More suitable as an auxiliary structure for internal placement.

- On the bolts. In this structure, the steps are attached directly to the wall with anchor bolts. It is distinguished by grace and airiness. They can have straight and curved spans.

- Duck step. Differs in compactness and steepest slope in comparison with analogues. Half rests, designed separately for the right and left legs. They are used with an acute shortage of free space. To make the steep stairs comfortable, several gentle spans with intermediate platforms are installed.

The staircase in the country can be made of metal or wood. The choice is made based on priorities, artisan skills and financial capabilities.

Calculations and drawings

Having chosen the type of structure, you can proceed to the stage of its design and procurement of the necessary materials.

When making calculations, you should adhere to the following rules:

- To determine the model of the structure, it is recommended to draw several sketches in scale and color. This will help you choose the best option that suits everyone.

- Experts recommend staying with wood. The material is easy to process, is inexpensive, lasts a long time, looks good in any interior.

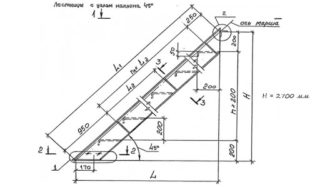

- For calculations, the parameters of structures for a private house adopted in construction are taken. The optimal width is considered to be 100-150 cm, the size of the steps is 25x18 cm, with a slope of 27-35º.

- Measurements are carried out directly at the facility. Each distance is checked at least three times to avoid mistakes.

- The number of steps is determined by dividing the length of all spans by the depth of one fragment.

- The height of the railing is taken at least 120 cm. If there are children in the house, the balusters are installed more frequently or a fence is placed between them.

- It is imperative that a detailed, understandable and accurate drawing is made, and an explanatory note to it with the sequence of performing all stages of work.

Any original buildings should be not only beautiful and interesting. Their main purpose is convenience and functionality, and their properties are reliability, safety and durability.

Necessary tools and materials for work

For work you may need:

- Bulgarian;

- welding machine;

- hacksaw for wood;

- level, tape measure;

- hammer, mallet;

- ax;

- plane;

- belt grinder;

- nail puller;

- stationery knife;

- shovel;

- ingredients for concrete mix (sand, cement, crushed stone).

You should also remember about your own safety. You need to prepare a helmet, insurance, gloves, goggles or visor.

Features of the work

There are two approaches to building a staircase. In the first case, the structure is assembled gradually directly at the installation site. In the second, it is delivered to the house ready-made.

General installation sequence:

- Marking. On the wall, if provided, the line of passage of the bowstring is applied. The place of the foundation pit is being established.

- A pit is torn off, a steel frame is immersed in it with mortgages for fastening the lower part of the bowstring and the first support for the railing. If a decision is made to make a screw structure, a central pillar is installed. Concrete is poured into the pit.

- Production of stringers in accordance with the previously developed scheme. Support structures are being prepared to secure them. If the staircase is laid inside, a hatch is cut into the ceiling and equips.

- Installation of stringers. Depending on the materials used, they are fastened with corners, self-tapping screws, welding, bolts or pins. Inside, this is done to the floor and ceiling, outside - to the foundation and upper platform at the front door.

- Installation of steps. It is carried out from the bottom up when the installed elements are used as a support for the master.

After climbing to a height of more than 150 cm, you need to use insurance, securing it to the already fixed steps.

Handrail and guardrail arrangement

The installation of the railings begins with the installation of the upper and lower supports. They determine the reliability of the entire structure and must be characterized by increased strength. The lower one is attached to the foundation, and the upper one to the ceiling. After that, intermediate racks and filling are placed at a certain interval, if provided for by the plan. From above, the balusters are closed by handrails, which are attached with glue, bolts or self-tapping screws.

The final stage is finishing. The tree is sanded, after which it is treated with an antiseptic, primer, varnish or stain. The metal is polished, cleaned from rust and scale, covered with bluing or paint.