The staircase is an important component of the construction of a house with a basement: without it, it will not be possible to enter the cellar. The structural features of such a design are dictated by the specifics of the place. The staircase to the cellar with your own hands is most often made of metal or wood.

Design selection criteria

The ladder designed to descend into the basement must be reliable and provide easy access to a dark room in a confined space. This imposes a limitation on the features of the device. Screw for most people will not be the best option: when using it, inconvenience can arise even when moving from one floor to another in a well-lit building. But if the tenants do not experience such problems, they may prefer this option as well. Its advantage is its compactness. Among all the main types of staircase structures, the helical is the most difficult to make on your own. If the homeowner does not have the relevant experience, it is better to entrust him with the calculations to specialists.

A do-it-yourself ladder to the basement is done quickly and is a completely functional option. It is often preferred for its ease of assembly. Another plus of the stepladder is that it is easy to carry it from place to place and use it for various household tasks, for example, to enter the attic. When creating such a structure, it is important to ensure the required stability. The lower parts should not be able to move when a person is on the stairs. You can organize for this recess in the plane of the floor.

Marching stairs are popular. When installing such structures, it is important to observe the dimensions and proportions: the step of the steps, their width, the rise of the tread. If the underground space is located at a shallow depth, the number of elements may be small. For a large basement, the number of steps increases. In addition to them, the structure includes load-bearing parts - beam or kosour. The step consists of two components - standing (riser) and parallel to the floor (tread). During installation, it is necessary to ensure the ratio of their dimensions, which provides comfort during ascent and descent. Especially inconvenience when using a ladder can be caused by excessive or insufficient riser height. You can find designs consisting of a pair of marches. In this case, an intermediate platform is mounted between them.

The leading parameters for a basement structure are stability, reliability, and the right size ratio. It is also important not to make the descent too steep. Attention is also paid to the water resistance of the material, especially if the air in the basement is characterized by high humidity. Design qualities can be neglected: the most important thing for her is functionality and practicality.

Materials for making stairs to the cellar

Before you make a staircase to the basement, you need to decide on the choice of material. The determining factors are strength and the ability to withstand heavy loads. To create such structures, hardwood, metal and concrete are used.

Wood

The advantages of this material are its low weight and ease of handling.For home stairs, kiln-dried wood raw materials are used. It should not have knotty places, crevices and other structural disturbances. Rotten raw materials must not be used.

Wood must be treated with compounds that protect it from moisture damage, as well as fire retardant impregnations. Treads can only be made from high-quality raw materials of hardwood - oak, birch or ash. Bars and planks should be geometrically even and well planed. This can be controlled with measuring instruments.

Metal

For the assembly of such a structure, steel or aluminum rolled products are used. In the first case, maximum reliability and resistance to environmental factors are achieved, but in the second, the ladder will turn out to be light. The metal must be free from corrosion or other defects. Channels and reinforcement elements are taken strictly new, not used.

The material is required to strictly comply with the specified parameters: brand, thickness and other dimensions. To extend the service life, it is recommended to treat it with an anti-corrosion compound.

For the manufacture of handrails, thin pipes or corners are used.

Concrete

To create a concrete structure, you will need cement and crushed stone. To give the form to be poured, it is limited by a contour - formwork. It can be made from steel sheets or boards. The brand of cement used must be at least M400: it depends on how strong and reliable the structure is. You will also need reinforcement: meshes are purchased for the steps, and steel rods are purchased to form the main frame. Their cross-section must be at least 0.8 cm.

Dimensions and slope of the stairs

Before making a staircase to the cellar, you need to take measurements and prepare a diagram of the designed structure. The drawing indicates the dimensions of all structural elements.

There are rules regarding basic dimensions: for example, the slope value must be in the range of 20 to 75 degrees. Readings over 45 degrees are usually used for attached structures. The smallest possible step height is 12 cm, the largest is 21 cm. The width of one element should not be less than 25 cm, otherwise it will be traumatic to climb. The optimal value for this parameter is 30-32 cm.

The number of steps depends on the depth of the basement and can vary from 3 to 16. The minimum width of the march is 0.7 m. If the area allows, it is better to increase this parameter to 1-1.1 m. This will increase the convenience of using the staircase and is especially recommended. if you plan to move large items to the basement.

The minimum allowable clearance value is 190 cm. It is calculated from the floor beam to the final step. The higher the ceiling, the more comfortable it will be for residents to climb. If the clearance is insufficient, you can easily hit the ceiling with your head.

Required tools and materials

To make a ladder out of metal yourself, you need to be able to handle a welding machine. The steps will be made from steel sheets. You will also need to purchase:

- metal corners with dimensions 50x50;

- reinforcement components;

- channel bars made of steel with marking No. 10;

- grinder.

To control the evenness of structural elements, use a tape measure and a level. You also need to prepare a drawing with dimensions.

For an attached structure, you will need two pipes with a cross section of 5-6 cm and a length of about 2.2 m, as well as cross-sectional profiles of a round shape of 25-30 mm in section. The number of the latter depends on the calculated number of steps, and the length should be identical to the intended width of the stairs (minimum - 0.7 m).

Making stairs to the cellar with your own hands

A suitable choice in terms of the ratio of ease of manufacture and reliability would be a metal ladder. This option is also convenient in that the build process is not tied to a specific place: to implement it, you do not need to be in the basement. From the tops of the pipes, a distance is set aside equal to the step height (for example, 0.3 m) and the first step is welded with a butt seam. Then the rest are installed in the same way, while the required height is observed when attaching each subsequent step.

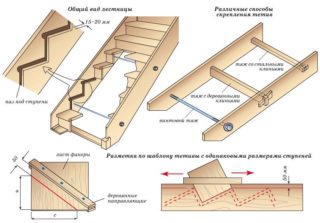

If the room is not characterized by increased dampness, you can also make a staircase made of wood. Before work, you need to soak building materials with anti-rotting compounds. First, stringers are cut out according to templates. Strict adherence to design dimensions is important. The sections are processed with a plane and then polished. The prepared bearing supports are attached to the upper floor by means of anchor and dowel elements. The distance between the stringers should be equal to the design width of the structure. For fixing to the floor, a corner is prepared with holes drilled on both sides. It is screwed to the structure and to the floor surface.

The vertical and horizontal parts of the steps are made of planks. They are sawn in accordance with the design dimensions, processed with a plane and polished. It is important to monitor the identity of the dimensions of the workpieces.

Begin the installation of two-component steps to the frame, moving from bottom to top. The vertical part is screwed on with self-tapping screws, and the horizontal part is put on top and fixed. It is especially important to check the flatness of horizontal boards - the safety of using the structure depends on it. This can be done using a level.

The staircase can be fitted with a handrail. To make racks for them, long beams with a section of 80 by 60 mm are used. They are used to prepare posts of meter length according to the number of steps. They are subjected to grinding and processing on a milling machine. The racks are attached to the steps, and then mounted on top of the handrail. It can be made from a polished block of sufficient length. The finished structure can be coated with a paint and varnish composition.