A solid, stable staircase is needed to the basement. Steps and braids are made of different materials, so the characteristics and designs are different. A wooden or metal staircase to the cellar should be comfortable, for which its project is drawn up taking into account the developed proportions that are used in construction.

- Choosing a staircase

- Requirements of normative and technical documentation and calculation rules

- Dimensions and slope of the stairs

- Drawings of stairs for the cellar

- Types of basement stairs

- Ladder

- Marching staircase

- Spiral staircase

- Materials and their features

- Brick

- Monolithic reinforced concrete

- Wood

- Metal

- Combination of materials

- Making stairs to the cellar with your own hands

- Ladder option for a novice master

Choosing a staircase

When drawing up the project, the quadrature of the cellar is taken into account in the part that is allocated for the installation of the descent. The parameter directly affects the length of the march, the height and depth of the steps, the slope of the stairs.

Pay attention to factors:

- Humidity in the basement. The material of the purlins and steps depends on this, as well as the degree of their processing before installation.

- The strength of the material, its durability. On the march, people are climbing with an additional load in their hands, which can have significant weight.

The choice is influenced by the financial capabilities of the owners. Some buildings are complex, such as folding or retractable, so their cost is high.

Requirements of normative and technical documentation and calculation rules

The regulations indicate that the structure is equipped with handrails with a height of at least 0.9 m, and the support posts of the fence are placed in increments of no more than 1.5 m. Handrails are not installed only if there are capital walls on both sides of the march.

Document-oriented:

- GOST 23.120 - 1978, which provides technical conditions for flight stairs and platforms;

- SNiP 2.08 - 1989, they indicate the norms of placement in residential buildings;

- GOST 25.772 - 1983, here are general specifications for the manufacture of steel stairs.

When calculating the structural scheme, it is taken into account that the width of the step for the convenience of placing the leg should not be less than 25 - 32 cm. A smaller size will make the rise inconvenient, and an increase in width will complicate it. The height of the step is taken in the range of 12 - 22 cm.

There is not always enough space in the cellar to fulfill such conditions. With a large steepness of the descent into the cellar, it is not possible to fit the required number of steps into the horizontal projection, the width of the elements is less than normal. In this case, on each step, a small forward release (no more than 5 cm) above the underlying part is provided. In another version, the issue is solved by installing inclined risers, while the size of the bevel does not exceed 5 cm.Only horizontal steps can be put, and the risers are not installed - then the leg will have full width support without a stop in the front part.

Dimensions and slope of the stairs

The staircase for the cellar should be of the same width throughout the entire length, the size of 0.7 - 0.9 m is considered convenient.

Other parameters of the march:

- if the entrance to the cellar has turns, make a platform 1.4 x 1.5 m so that you can turn around with a box, a bag;

- instead of a platform, rotary steps with a total length of no more than 1 m are allowed;

- the slope of the span should not exceed 20 ° - 75 °, but steepness greater than 50 ° is used for stepladders and attached models.

On the steps, adjustments are made of corrugated metal, rubber.Details reduce the degree of sliding, extend the service life.

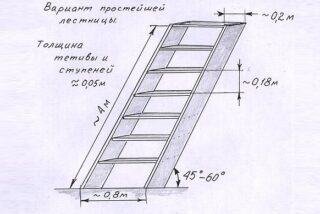

Drawings of stairs for the cellar

The descent into the basement is difficult to do without scrupulous calculation and drawing all the elements on paper. Coordinate the height, width, steps, slope angle, while the whole structure should organically fit into the gap. It is taken into account that the dimensions of the elements must be the same.

The height of the opening is taken such that a tall member of the family passes into it, standing on any tread of the stairs at full height. In this case, the person should not touch the ceiling or beam with his head. Usually, the height dimension is taken at the level of 1.9 - 2.0 m.

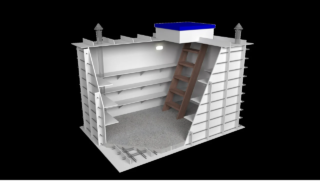

Types of basement stairs

Each cellar has individual conditions for organizing the descent. It is more difficult to make stairs in small basements.

There are basic designs:

- attached;

- marching;

- screw.

The gangway to the caisson cellars is also very complex, in which the march protrudes into the street and rises above the ground in a special vestibule.

Ladder

A common variant of the descent at the entrance to the cellar. They are made from a metal pipe, round or profile section, using a steel corner.

Suitable for low basement heights. Types of structures:

- removable;

- in the form of a pull-out section;

- folding;

- rigidly fixed at the bottom and top.

Provide a small gap between the ladder and the wall for ease of use. Sometimes there are racks nearby to take cans and other items while on the stairs. On stationary installed attached models, side handrails are made.

Marching staircase

Such models cannot always be built due to lack of space. The march can be straight or with a turn at right angles, made of different materials. Two marches are connected by an intermediate platform or turning steps.

This variety is characterized by:

- a gentle, comfortable slope;

- handrails on one or two sides;

- the ability to combine different materials in the manufacture.

It is impossible to rearrange the structure, therefore, before manufacturing, the dimensions of the elements are calculated and the place is carefully chosen. They are made of metal, concrete, wood.

Spiral staircase

The design does not require much space; it is placed in small basements. It is not always convenient to use a staircase of this type due to the specific location of the steps and their shape. Screw gangways are placed in the middle of the basement or next to one of the walls.

At the bottom, near the march, a space is provided so that you can get off the steps and go around the structure from the other side, where vegetables and boxes of food are located. A spiral staircase can be made with a central post to which the steps are fixed, or several supports can be made in a circle.

Materials and their features

Durability, type of construction, care and ease of use depend on the choice. For stairs, brick, reinforced concrete, wood, steel are used.

Brick

The material is rarely used, since the laying of small-sized stones is laborious. The staircase turns out to be heavy, so a reinforced concrete base is made for it.

Features of brick construction:

- strong, durable;

- requires finishing on the sides and steps;

- made of ceramic fired bricks, since there may be moisture in the cellar;

- the steps along the edge are framed with a steel profile in the shape of a corner.

Brick is an expensive material. Niches for storing food can be made inside the side surfaces if they are freely accessible. The direction of the exit can be rectangular or semicircular, it all depends on the layout of the basement and the location of the shelves.Such a structure can be folded by an owner who has little experience.

Monolithic reinforced concrete

By analogy with a brick, such a staircase requires extensive space and is placed in a large cellar or basement, combined with a garage.

Pouring of concrete is quick, but it will take a long time to prepare:

- foundation device;

- waterproofing;

- fabrication of a reinforcing cage;

- exposing the formwork.

After laying the mixture, it will take 28 days for the concrete to gain strength, but you can use the steps for 14-15 days. The surface needs to be looked after - cover with sawdust and sprinkle with water every day so that cracks do not appear. Concrete is prepared at a concentration of 1: 3: 5 (cement M400, river sand, crushed stone of medium size, respectively).

Wood

It belongs to the category of popular materials due to its availability and low cost. The staircase can be made independently by any owner of a private house.

Manufacturing features:

- before installation, all wooden parts are treated with an antiseptic to exclude the development of microorganisms in the body;

- elements are impregnated with fire retardants to increase the resistance of wood to fire;

- dry material with a small number of knots is chosen for construction;

- the installation box of the ladder is painted to prolong the life.

Treatment with protective agents is repeated periodically, so the wood will not collapse from time to time in conditions of high humidity in the basement.

Metal

Steel stringers with welded metal steps are also a popular option. For the manufacture they take, channel, corner, Tavr, I-beam, use a professional pipe. Welding and installation does not take much time compared to masonry and concrete casting.

The staircase to the basement is made of metal using a welding machine, so you need to be able to work with it. Metal elements are treated with an anti-rust agent, painted with oil and pentaphthalic compounds to increase corrosion resistance.

The steps can be in the form of a lattice or solid. The handrails are also made of iron. The products are notable for their small mass, therefore, they provide for recessed pillars on which the stringers rest with their lower ends.

Combination of materials

The variant with the use of several types is very common. Inclined runs are made of one material, and the steps are made with another.

Common combination of materials:

- wood and metal;

- concrete, wood and steel;

- brick and iron;

- brick and wood.

Brick steps are finished with steel plates, they also come with concrete and wooden elements. Railings are often made of iron, and they are installed for brick, concrete stairs. The structure of the fencing also combines iron posts and timber handrails.

On metal girders, the frame of the step is welded from the corner, but the filling is made from boards. Iron gratings are installed on concrete surfaces to prevent slipping.

Making stairs to the cellar with your own hands

Two kosour are cut out of the beam, on which the steps will lie. For cutting, use a hacksaw for wood or use a circular saw.

Operating procedure:

- a fastening stop is cut out of the board, fastened to the floor and ceiling, girders are attached to them;

- treads and risers are cut out of a thick board according to a pattern, sanded;

- the steps are fixed to the stringers with self-tapping screws, pins, bolts.

After installation, all parts are painted and varnished.

Ladder option for a novice master

The combined option is best suited, but everyone chooses the materials at their own discretion.For example, you can successfully make a concrete structure, the scope of work is simple, you just have to tinker.

A metal staircase will take the least time, so the option with overhead steps from a different material is also suitable for a person without work skills. Welding parts is not so difficult, you can ask for a few lessons from an experienced craftsman.