Even in the smallest bath, it is necessary to install furniture, and special furniture. Ordinary benches are not suitable for a steam room; linden or aspen shelves are made here. Designs and sizes are selected based on the dimensions of the room.

- Requirements for bathroom furniture

- What material to choose

- What items should a set of bath furniture consist of

- Manufacturing of furniture for the steam room

- Manufacturing technology of a bench for a steam room

- Production of a two-tier shelf

- Manufacturing of furniture for washing

- Installation of a wooden font in a washing room

- Furniture for utility rooms

- DIY wooden chairs and stools

- How to process wooden furniture for a bath

Requirements for bathroom furniture

Do-it-yourself bathroom furniture made of wood is made exactly as intended and must meet special requirements.

- In the steam room, the humidity reaches 80%, and the temperature rises to 60 ° C. Only deciduous species that are resistant to moisture and steam can withstand such loads. The steam room is equipped with benches of a special design - shelves. You can take a steam bath while sitting, reclining and lying down. For a seated steam room, benches are made with a seat width of 45 cm and a small length. For a prone position, the bench should be 185 cm long and up to 60 cm wide.

- In the sauna, the temperature is even higher - up to 120 ° C, and the humidity is noticeably lower. They approach the choice of wood for furniture more carefully: if the wood heats up too much, you cannot make benches from it - you can get burned.

- Washing room - at a comfortable temperature not higher than + 25– + 30 ° С, humidity reaches 100%. Here you need traditional benches with backs, a chair for those who find it difficult to take a shower while standing, bathrooms, as well as barrels and ladles.

- Dressing room - standard temperature and humidity. A hanger for things, a bench for convenience is attached here.

If the bath has guest rooms or rest rooms, the latter are chosen depending on the desired degree of comfort. There are no restrictions.

What material to choose

Only special items are called furniture for a wooden bathhouse made by hand. The leather sofa in the break room does not apply.

The shelves and benches in the washing room must withstand large changes in temperature, steam and moisture.

Conifers - pine, spruce, larch. They are resistant to water and not prone to decay, but only due to the large amount of resinous substances. At high temperatures, resin is released onto the surface of the tree, staining it. In addition, the resin heats up much more than wood and can burn.

Softwood benches and hangers are made for a washing room or dressing room. Pine and spruce cannot be used in a sauna or Russian bath.

Deciduous - hard species, like oak or beech, only become harder from water. Soft and medium density - birch, poplar, cherry, are not suitable. However, for a steam room, another parameter is more important: a relatively low thermal conductivity. Therefore, furniture for the steam room and sauna is made of linden, aspen, alder.

In the dressing room, they put furniture made of any tree.

What items should a set of bath furniture consist of

DIY bath furniture includes the following required minimum.

- Shelf - single or multi-stage. Linear, if placed along 1 wall, L- or U-shaped, if along several. Its device is the same both in the steam room and in the sauna. Often, the kit is complemented with a footrest. The shelf is wall-mounted. This furniture does not carry over from place to place.

- A do-it-yourself wooden sauna chair is required in the washing and dressing room.Even if the steam room is combined with the washing room and the user is simply doused with water after the procedure, basins of water, buckets, barrels must be placed somewhere. A low chair, a stool is perfect for this.

- It is better to install a bench with a back in the dressing room. It is more comfortable than a chair. The obligatory item also includes a stand with hooks for wearables. It's not bad if there are a couple of shelves for towels, bathrobes, hats, and other bath accessories.

In addition to the shelves, all other furniture belongs to the usual floor furniture.

Manufacturing of furniture for the steam room

Bath furniture is extremely simple. Allows you to use improvised materials, such as knotty wood, sawing logs, stumps, to show imagination and ingenuity. Used for crafting only wood.

To fasten the parts of the benches in the steam room and sauna, it is allowed to take only wooden nails and chopiks. Iron fasteners get very hot, the user runs the risk of getting burned by accidentally touching a nail. When creating furniture for a washroom or dressing room, you can also use metal fasteners.

Manufacturing technology of a bench for a steam room

The shelf consists of a frame and flooring. The frame is assembled from vertical racks and connected with jumpers. The furniture is immediately attached to the wall during the manufacturing process.

The step-by-step instructions are simple.

- According to the calculations, a drawing is made. It makes it easier to make an estimate.

- Determine the general design of the benches and their placement - linear, L-shaped. If, for example, the shelves are placed in a corner, then a more complex vertical rack must be made for the corner section.

- Before assembly, the wood is treated with sandpaper or a grinder, the ends are rounded. They are impregnated with anesthetics and fire retardants, and after drying, they are polished again.

- Racks are assembled from bars with a cross section of 50 * 50 or 50 * 70 mm. Most often they have a step-like design. Fastening - a thorn in a groove or on wooden nails.

- The supporting racks are fixed to the wall with screws or self-tapping screws. It is recommended to fasten them to the walls through small pieces of wood to prevent wood from rotting. The step between the posts is 60–85 cm.

- The racks are connected with crossbars from the same timber.

- The resulting structure is sheathed with boards 10–20 mm thick. A gap of 1–2 cm is left between the slats so that the steam passes freely between the boards and warms up the body.

- In the sauna, the vertical space between the seats of the 1st and 2nd level or 1st level and the floor is also sewn up. This should not be done in a steam room.

Benches can be supplemented with backrests for support, side handrails, footrests.

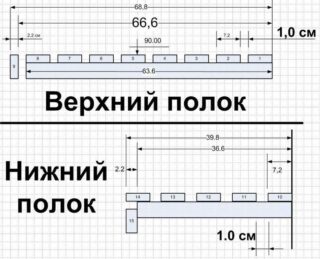

Production of a two-tier shelf

The two-tier structure can withstand higher loads. The walkthrough includes several additional steps.

- Before assembling the rack at the level of the beds of 1 and 2 levels, a wooden block with a section of 10 * 10 cm is attached to the wall.

- The assembled two-level racks are installed on the bars and fixed to the floor - here you can use metal corners.

- For jumpers, a more massive beam is used.

The thinner the board is used for sheathing, the smaller the distance between the supports and the more massive the beam must be used for the frame.

Manufacturing of furniture for washing

The washroom furniture is exposed to high humidity. The temperature drop here is less, but there is: the home bath is heated only during use, in winter, after cooling down, a low temperature is set here.

Since there is no high temperature in this room, the tree can be protected. The slats and timber are impregnated with antiseptics, stains before manufacturing, after manufacturing they are treated with wax, oil, varnish. It is even allowed to paint with waterproof paints.

The wood must be carefully sanded and the ends round off.

The wash bench is assembled in the reverse order.

- On a flat surface, lay at least 3 boards 10 cm wide, face down.From the ends between the rails, inserts 1 cm thick are placed so that a gap remains during installation.

- They retreat from the edge of the board 20 cm and fasten the boards to the transverse beam with ordinary nails. Do the same from the opposite side.

- Assemble a rack with legs - in the form of the letter "P". Below, at a distance of 10 cm from the floor, the rack is fastened with an additional crossbar.

- A block with legs is placed near the cross member and fixed to both the bar and the seat boards.

- If desired, the bench can be supplemented with a back.

Shelves are often placed in the washroom. They are made only open, otherwise moisture accumulates here and the tree rots. The shelves are knocked down from a pair of slats or placed on a block. They are fixed on the wall with self-tapping screws or on a metal corner.

Installation of a wooden font in a washing room

Instead of a shower, you can use a more traditional washing product. There are several options for the font.

- Bulk - a wooden bucket fixed on hinges. Pulling on the rope, the bucket is overturned and poured over with warm or cold water. For a small bath, where a steam room is combined with a washing room, this model is most suitable.

- Floor standing - bathroom option. You can make it from a regular barrel. The shape for the font is often chosen oval. Since her height is large, they make a bench for a seat and a ladder inside.

- Stationary - in fact, a mini-pool, trimmed with wood. An interesting, but more complicated solution. Typically, in the washroom, such a font becomes the centerpiece.

The material for the product is linden, sometimes cedar.

Furniture for utility rooms

Auxiliary in the bath are considered to be a dressing room, a vestibule, a changing room, a recreation room, and a guest room. Furniture in the guest room is rarely done by hand, but the dressing room or dressing room is equipped independently.

Hanger - in the simplest cases, it is a shield or board with hooks fixed to it. It is often made from unusual materials. For example, cut knots are fixed on the board instead of hooks, the shield is knocked down from the cuts of the trunk or curved raw branches.

A table and a wooden chair are placed in the recreation room. It is better to make a bench comfortable - with a back and side handrails. They try to make furniture in the old style: rustic, rustic, chalet style. It is better to put the table on not straight legs, but on crossed ones and on supports. Often, models are decorated with decorative metal elements.

With the small size of the dressing room, the stationary table is replaced with a wall folding table. However, this is a rare solution.

DIY wooden chairs and stools

For a stool in the dressing room, you will need 4 bars with a cross section of 50 * 50 mm, processed to smoothness, 2 or 4 pieces of boards 12-15 mm thick, or a piece of plywood. You will also need bars of 30 * 30 mm for tsars and prinots.

The step-by-step instructions are simple.

- The seat board fragments are carefully cleaned. Smear the ends with glue and leave the seat in the clamps until the glue dries.

- On the legs, they mark the grooves for the tsars and prongs, if any, and choose the grooves with a chisel.

- The edges of the tsars and princesses are processed by cutting off excess wood. In this way, spikes are obtained with the same depth and width as the grooves on the legs.

- The legs are connected in pairs with tsars and prinots. The spikes are greased with glue before joining. The frames are left in the clamps. After the glue dries, the fasteners are duplicated with self-tapping screws.

- The upper frame of the frame is greased with glue, the seat is placed on top and pressed. Fasteners are duplicated with wooden dowels.

The seat can be shaped in different ways.

How to process wooden furniture for a bath

Furniture is processed and decorated according to its purpose.

The shelves in the steam room and sauna must not be painted; it is undesirable to treat with oils and impregnations. These materials are difficult to withstand changes in temperature and are not always resistant to steam. They use wax, oil wax. It is allowed to use polyurethane-based varnish marked "for steam room".

In the washing shop, they are treated with waterproof varnish and paints.Wooden fonts and barrels are not varnished. Oil and wax are used to finish them.

Furniture in the dressing room can be painted, varnished, treated with stains and oil. The choice depends on the desired decorative effect.