In the construction of the iron door block there is a frame with a threshold and a canvas of the appropriate size to cover the opening. The sash pivots on hinges and is limited by the rebate in the closed position. Home owners make a metal door with their own hands in order to make a design according to their own taste and save money. There are many materials for the exterior decoration of the canvas, and the junction of the patch with the wall is decorated with platbands.

Necessary equipment and tools

It is not difficult to weld the box and the canvas, but this requires certain fixtures and tools. As a result, you will get a product that in finished form will be cheaper than a purchased iron door from a store. Working with a welding machine requires a certain skill, so you need to invite an experienced friend so as not to digest the seams. The unit can be taken of any type, for example, a transformer, an inverter, or a semiautomatic device.

Other tools for metal door fabrication work:

- grinder for cutting profile, metal and leveling the area of joints;

- tape measure, square, core for marks on metal, chalk;

- clamps, pliers, hammer, chisel;

- cutting discs for steel for grinders, grinding wheels;

- electric drill with a set of drills, screwdriver, Phillips screwdriver.

Work is often carried out on the ground or asphalt. It is better to use a large metal table with a horizontal surface. You can put two small goats for assembling the elements of the box and hanging the canvas.

To install the block in the opening, you will need a perforator to drill holes in the end of the wall and a drill with a metal anchor with a winning diameter.

Materials for making

The main one is sheet metal, rolled metal for the manufacture of loot and banding. You can make a door from a profile pipe or use a corner, channel. The section of the square is taken 20 x 40 mm, the corner is 50 x 25 mm, for a powerful block they put a larger number. The size of the channel is also adjusted to similar parameters.

Material is harvested for a strapping and a box in the amount of 20 running meters. This amount of rolled products is enough to make a block 2 meters high and 1 meter wide. A metal sheet is prepared for the sash, the thickness of which is not less than 2 - 2.5 mm, and in size it should be 1 x 2 meters.

In addition to metal, you will need:

- Bearing hinges. The metal door has a significant weight, therefore, they suggest not 2, but 3 canopies.

- Lock. The type of locking device is chosen by the owner at his own discretion, guided by the price.

- Pens. They can be supplied with a lock or sold separately. It is recommended to use steel handles, since plastic and ceramics will not last long.

- Door closer. The device will slowly return the sash to the closed state and slam it.

- Peephole. The optical device will show what is happening behind the door.

- Insulation for the canvas. They put foam plastic, extruded polystyrene foam, mineral and glass wool.

- Sash clamping seal. Use rubber options with polyvinyl chloride additives.

- Exterior cladding material such as imitation leather, plywood, boards or wood veneer.

The composition of materials may vary depending on the design of the unit (one or two doors, swing or sliding). Insulation is placed between the metal and the decoration, or a steel cover is made on both sides of the protective layer.

Handles are stationary in the form of a simple bracket and a latch handle. The first type contains no moving parts and is not associated with a locking mechanism. Staples come in a variety of sizes, thicknesses, and shapes. The second type is more functional, it is produced with a push or pivot action.

Advantages of a homemade metal door

If the master welds a door from metal with his own hands, following the technology, he will be sure that the product is of high quality. Many manufacturers put steel thinner than the prescribed size, but declare compliance with the standard. It is impossible to verify this, therefore, hand-made production is reliable.

The quality of the steel for the blade also matters. For the entryway, the owner will take the metal of the specified thickness. The difference seems insignificant between 1.5 and 2.5 mm, but home burglars do not carry powerful tools with them, so every tenth of a millimeter will delay the destruction of the canvas. With his own hand-made production, the owner will not take steel thinner than 1.5 mm, since the sash is simply deformed, unable to withstand its own weight.

The advantages of making a metal door with your own hands:

- using only high quality materials;

- exact adherence to dimensions;

- creation of a unique decorative surface for the existing interior;

- cheaper compared to a ready-made design from a store.

Iron more than 3 mm will make the structure heavier and the canvas will be difficult to open. We'll have to install reinforcing parts, which will increase the cost of the door block.

Manufacturing of door frame and door leaf

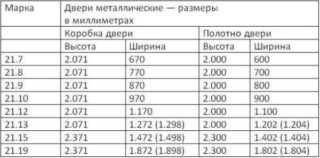

The frame is made after measurements of the opening at the installation site. Measure the height on both sides, then the width at the bottom, top and middle. They draw up a drawing of a metal door, where they put down the dimensions and find the optimal dimensions of the box. Gaps are also left between the canvas and the box, with the edges of the sheet protruding from the sides of the frame.

The dimensions of the block and the canvas are taken taking into account the following points:

- the product must have right angles and fit into the opening, even if it is slightly skewed;

- on each side, there should be a gap between the end and the lute of 1.5 - 2.5 cm;

- the seams on the canvas should be no longer than 4 cm, and the gap between them should be 20 cm.

A metal profile for the box is cut according to the established dimensions. Lay out the structure on the welding table. The corners can be joined at 45 ° or joined at right angles. It is important that the diagonals of the resulting frame rectangle match exactly up to 1 mm.

Further work order:

- Cutting the web is started after welding the loot. The internal dimension is measured and it is taken into account that the sash must fit into the box with a 1 cm gap around the perimeter.

- In the metal profile from the side of the lock, a slot is made at the installation level of the locking device.

- For the convenience of work, the profile where the hinges will be must be welded immediately with the hinges and the box. Measure the distance between the elements so that everything matches.

- Check the parallelism of the surface of the sash and the sash, then the sheet is put into the frame and the remaining strapping profile is welded. It is taken into account that the vestibule accounts for 10 mm on three sides, and 15 mm is left for this from the hinge part.

First, a part of the block is fastened, which is located on the side of the canopies from the reverse side of the sheet on the inside, then the strapping of the canvas is fixed along the entire perimeter. The porch in the form of a strip is attached to the back of the steel sheet. To prevent the sash from turning inside out, stiffeners are placed, which must be welded to both sides of the strapping frame of the canvas.

With the help of a grinder and a grinding wheel, they clean the surface of the seams, making them flush with the surface of the metal. Metal structures are painted in any case, even if decorative upholstery then follows.

DIY installation of door hinges and a lock

The lock is placed in the middle of the box along the block height. Mark its location and cut longitudinal grooves on the wide sides with a grinder. In narrow areas, a drill is used to drill a pair of holes. After that, break off the designated area with a hammer and chisel. Next, holes are drilled to fix the lock and keyhole. Do not forget about the holes for installing the decorative lock plate. In the box, you need to make mating recesses for the tongue.

The hinges are made of steel rods with a diameter of 2 cm, while the inlet and the counterpart from a pipe of a suitable section are welded simultaneously to the sash and the box.

Installation instructions for awnings:

- The canvas is placed in a box, a spacer (a couple of coins) is placed between them so that a gap of 4 mm remains. So the seal will fit perfectly, and the moving section of the loop will not rub against the strip.

- It is better to make the front door with the assembled awnings so that the axes of the three hinges coincide completely. If the condition is not met, the sash will open or close under its own weight. Another nuisance will be that the hinges will not be able to stand at the same time when the canvas is being hinged.

- The sheet is placed with the cut side to the hinges. It is not possible to obtain an ideal edge, so it is hidden from the sides of the canopies, where the cut will not be conspicuous.

The rod part of the canopy is placed from below, otherwise in the future it will not be possible to remove the blade from the hinges for maintenance. For convenience, a ball is placed in the rod - this will make it easier for the door to move.

Installing the door handle

Markings are made on the side of the door leaf and the end. On the pediment, they additionally find the center of the end and indicate the place of drilling for the latch of the latch type. On the side of the canvas, a mark is made for the opening of the square of the handle, this size is marked similarly on the surface of the sash. This results in two drilling locations.

Pen drills are used, for the end face 22 mm, and a straight hole is made with a 25 mm drill. The canvas is drilled from the front and back sides so as not to damage the decorative layer. Further installation consists in assembling the handle with a latch inside the door leaf. The latch is inserted from the end and fixed with self-tapping screws.

They check the operation of the latch so that it does not jam from metal dust that has got into its mechanism. Then the square is mounted - it is placed in the hole of the corresponding shape through the frontal slot. First, a handle is placed on the square from one side of the sash so as not to confuse the right and left handle. For fixing, use three self-tapping screws provided in the kit.

They also put a second handle, after which they check the functionality of the elements. The levers should rotate, and the latch, under their control, move along a given amplitude. Decorative caps are put on the handles to close the docking points, the countersunk fixing screw is tightened from below with a hex wrench.

Metal door finishing

Rubber is laid for sealing after welding metal, installing fittings, to finally make an iron door. Holes are drilled on the top and bottom of the box to accommodate the fastening anchors when installing the door block into the wall opening.

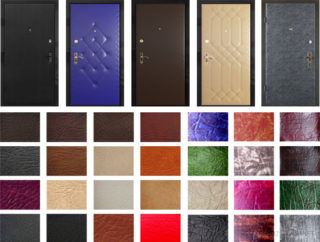

Finishing the outer and inner surfaces involves the use of different materials:

- artificial leather;

- PVC film;

- veneer;

- coloring.

The first option is popular and inexpensive. The surface, finished with artificial leather substitute, is almost maintenance-free, sufficiently durable against abrasion. The material is available in different colors and textures.For upholstery, self-tapping screws are used or the canvas is glued to the iron with special adhesives.

PVC film belongs to the group of quality coatings for steel doors. The material does not fade in the sun, it has a stable color. Such surfaces are easy to clean, do not deteriorate from alcohol, alkali, there are no components harmful to humans in their composition.

The veneered layer on the canvas is attributed to the original style, while the sash looks like it is made of wood. A thin layer of wood can be of different colors, therefore it is selected for interior styling. This finish is more expensive than films and artificial leather, but looks better.

Spray varnishes, acrylic enamels are used for painting. The surface is preliminarily treated with sandpaper, then putty (automotive) is applied in places where there are minor scratches or irregularities. After drying, sanded with fine-grained emery and primed before painting.