A small brick wood-fired summer cottage is an excellent solution for periodically visited small buildings. Compact heaters take up little space, but at the same time perform a lot of useful functions. A small brick oven for a summer residence can heat a room, dry clothes and shoes, and be used for cooking and heating food. Improved models heat water in an amount sufficient for washing dishes and performing hygiene procedures. The products are absolutely safe, strong and durable. It is not difficult to make a small stove in the country house out of bricks with your own hands, but there are a number of nuances, knowledge and consideration of which is a condition for achieving a high-quality result.

Materials for the construction of a brick stove

The use of bricks is considered a classic, since this material has all the necessary qualities - strength, heat capacity, resistance to dampness and temperature extremes. Not every type of block can be used for laying a hearth.

For the manufacture of the firebox, it is allowed to use only fireclay bricks designed for heating up to 2000 degrees. Used stones do not have the most presentable appearance, but in terms of quality they are not inferior to new products. Red clay brick is quite suitable for laying the hull and chimney. It is inexpensive, there will be no problems finding it.

As a binding solution, a mixture of clay and sand is used for the furnace and with the addition of cement for parts of the hearth that are not heated above 50 degrees.

A brick stove for a summer residence is completed with a fairly large number of metal parts.

For assembly you will need:

- refractory wire;

- cast iron furnace doors;

- doors for cleaning smoke channels;

- grate;

- cooking deck with rings;

- steel sheet for the hot water tank;

- handles and latches.

If you plan to make a niche for the fireplace, you will need tempered glass, better tinted.

Varieties of furnace designs

Home stone hearths differ in several design features that characterize their functionality and performance.

The following classification has been adopted regarding the design of furnaces:

- For heating. Initially, they are intended for heating a room, in most cases they also serve as a decorative element. Smooth walls are decorated with tiles, clinker or tiles.

- With a hob. In addition to heating, such devices make it possible to cook in warmth and comfort, and not in a blown summer kitchen. The downside is that the hearth quickly cools down through the stove without realizing the potential heat capacity.

- Combined models. The constructions have a complex design and several tiers of options, which include an oven, fireplace, stove, heating screens on the floors located above. A water heating tank is provided.

- Multifunctional ovens. In addition to a variety of cooking and heating devices, they are complemented by sun loungers, niches and shelves. Two or more furnaces are made with separate blowers, ash pans and chimneys.

When designing a heating structure, permanent and temporary systems are selected, direct-flow, channel and bell-type, indoor and outdoor.

Furnace device for giving and its features

The device of a compact wood-burning stove does not fundamentally differ from its larger counterparts.

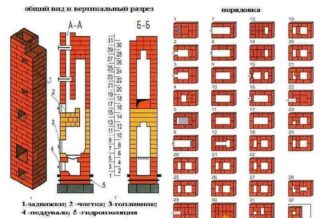

Products consist of the following parts:

- Foundation. Serves to give stability to the structure during operation.

- Body (body). Designed to accommodate objects that determine the performance, safety and functionality of the product.

- Smoke ducts. They are made for more efficient use and distribution of thermal energy released during fuel combustion.

- Firebox. A compartment designed to accommodate fuel. Equipped with a grate and a smoke outlet.

- Chimney. Serves to remove combustion products from the furnace and create the necessary draft.

- It blew. Air intake for burning the logs. Combines with ash container.

All other options are derivatives and complement the basic design.

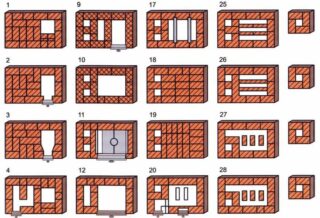

Varieties of orders

Novice craftsmen can use one of the well-proven small hearth projects:

- With a single burner panel. It is done literally within one working day. The body rises to a height of 80 cm, a plate is placed on top, a grate is inserted inside, a steel pipe is led out into the street through the wall.

- For heating adjacent rooms. The hearth is equipped with a register with pipes, a radiator and an expansion tank. The circulation of the liquid is carried out due to the difference in the mass of the heated and cold media.

- With a shield and a low trestle bed. A heating device where the generated heat energy is almost completely used. From the firebox, smoke enters the channels under the lounger, and only then heats the flap on the chimney located on the second floor.

The choice of order should be done immediately, since the dismantling and alteration of a brick oven is a very difficult undertaking.

Calculation of basic parameters

If the chimney is also laid out, it takes 56 pieces per linear meter of height. Clay needs 30 kg, and cement 70 kg per 100 pieces.

Metal parts are purchased according to the size and quantity of the project.

Required materials and tools

For work you will need:

- Bulgarian;

- hand drill;

- roulette;

- shovel;

- rammer;

- mallet;

- Master OK;

- a stepladder if the structure is taller than 150 cm;

- protective equipment - glasses, helmet, respirator, gloves.

Materials must be purchased in accordance with design calculations, paying attention to their quality. You should take 10-15% more bricks than the need, adjusted for battle and errors.

Do-it-yourself oven masonry

It is better to make a hearth at the stage of building a house, but there is nothing to worry about if you do this after its completion.

The following step-by-step instructions are recommended:

- Erection of the foundation. The depth of the laying should be below the level of freezing of the soil without being tied to the base of the house. To reduce costs, you can use pile or bored technology.

- Furnace masonry. First, dry fitting, trimming and fitting of blocks is carried out. Then the waterproofing is laid, the solution is prepared and the laying is done. Difficulties will not arise if you follow the order exactly. Seams between stones should be made with a thickness of 5-7 mm, controlling the dimensional accuracy.

- Chimney outlet through the roof. A hole is made in the ceiling between the beams, a sleeve with a basalt wool filler is inserted into it. A similar structure is installed on the roof covering.

- Facing the structure. Here the choice is made in accordance with the priorities of the hosts. You can limit yourself to painting or whitewashing, or you can fork out for expensive clinker or tiles.

The first kindling of the stove is carried out after two weeks of drying. First, newspapers, grass and branches are burned, then after two hours the fire is brought to maximum and maintained for at least four hours.

good day! was on your site and saw the oven at the very beginning. could you tell me the name of this oven, its calculation of the main parameters and order