For repair work and other manipulations with the car, good lighting in the garage is necessary. The choice of lamps and wiring diagram is necessary taking into account the layout of the room and the power source used.

Selecting the type of lighting fixtures

To decide which is the best to put lamps in the garage, you need to understand the difference between them. The devices differ in the principle of operation and the amount of light flux per 1 W of electricity.

Incandescent and halogen lamps

Incandescent lamps are a budget option. They function due to the ability of the tungsten filament to generate heat when an electric current flows, due to the high resistivity of the material. As a result, the thread heats up and emits a warm light. The advantages of such products, in addition to their price, are the ability to work at different ambient temperatures, the absence of blinking, the ability to turn on the light bulb a large number of times. Cons - significant energy consumption (40-80 W) and not too long service life (up to a thousand hours).

The sealed flasks of the halogen models are filled with gas, which increases the temperature of the thread. This design extends the service life of the product up to 5-12 thousand hours, while they consume less energy, but the bulb gets very hot during operation.

Neon lights

In terms of performance, this is one of the best garage lighting options. LED strips and lamps are often used in non-residential areas and can provide both warm and cold light. They are immune to subzero temperatures, humid air, voltage drops. Installing such lamps in the garage will cost more than other options, but they consume little energy (5-14 W) and can work up to 25,000 hours.

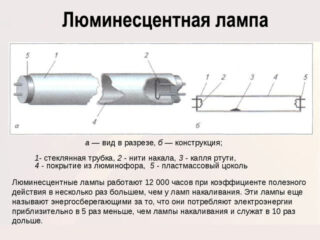

Fluorescent lamps

The most whimsical option for garage lamps. They have a low power consumption (10-20 W), but the choice of them as the main light source is not considered correct. This is due to its high susceptibility to frost, dampness and power surges. If the room is not heated, such devices are duplicated by LEDs or incandescent lamps. In addition, products must not be disposed of with general waste.

Choosing a scheme

Overhead lighting fixtures are suitable for general garage maintenance. They are easy to mount on a ceiling or wall. The following requirements are imposed on devices:

- closed design with high-strength protective glass;

- a metal grill mounted on top (placed on products placed below a meter from the floor);

- a diffuser is installed in the path of the luminous flux;

- devices should be evenly spaced over the area of the room.

The local system helps to illuminate specific areas - a table, a workbench, certain parts of a car. Devices must be securely fastened in a given position and not interfere with operation. If there is only one lamp, you can choose a portable product.

They begin to equip garage lighting with the selection of lamps: their type, number, power and determination of installation points.It is important that most instruments are directed to work areas.

A simple lighting scheme for a garage includes a voltage-reducing transformer for LED devices (you cannot use a 220 V network), automatic machines (input, for sockets and power), wires, RCDs and consuming components. The input to the distribution box must be grounded, while the resistance should not exceed 4 ohms. When the wiring is not connected to the home network, an electricity meter is used. The sockets are installed at least 0.8 m from the floor. A quick and economical option to illuminate a room without power is a rechargeable luminaire.

For a garage with dimensions of 4x6 m, the serviced area will be 24 m², so the required illumination rate will be 24 * 20 = 4800 lm. Knowing the light output data of the bulbs that will be used for the circuit, you can determine their number.

Local lighting can be achieved using a tripod-mounted spotlight, a portable flashlight, or a light bulb placed above the table. Devices that are part of a common network are often installed on the ceiling or at the joints of wall planes that form corners. Sometimes they are placed on the walls themselves.

Installation work

For work, you will need an electric drill and a hammer drill with a set of drills suitable for the material from which the walls are made, as well as a screwdriver. You also need to purchase a multimeter. The screwdriver and gloves must be electrically insulated. You also need to prepare a level and pliers. The cross-section of the cables used for wiring is selected according to the tables, taking into account the rated electric current and power.

The walls are marked with the places where the devices, junction box, switches and sockets will be located. Then they check that the wiring fits comfortably in the path of the planned laying, and put the car in the garage. If the arrangement of the system elements is comfortable, the car is taken out and holes are drilled for the installation of the main components. Then the walls are grooved, a box is attached to them and a cable is threaded into it. When the introductory board is installed, the wires are connected to the machines. It is necessary to check that the input devices and the RCD are connected correctly. After the installation of sockets and lighting fixtures, the system is tested for performance.

The input device is mounted next to the entrance to the room. If there is a viewing hole, it is allowed to put your shield in it. These devices themselves are type-setting. In a regular garage, 3 output machines are mounted, in a pit equipped - 4.

A low-voltage circuit is required for the inspection pit, since high humidity creates corresponding safety requirements. Permissible maximum DC current - 24 V, AC - 36. Power is supplied by the system from a transformer, stabilizer and rectifier. The light stream should be directed to the underside of the vehicle. Automotive transformers cannot be used.