Cooking on a fire allows you to get tasty and healthy food, which is especially important today when it is difficult to find organic products. An excellent solution for a summer residence is a do-it-yourself stove for a cauldron made of bricks. This is not an easy matter, but with a competent approach, even a beginner can do it.

Types of ovens under the cauldron

Your own plot gives you complete creative freedom in terms of designing a street hearth in terms of its size and configuration.

Stove options:

- Metallic. There are varieties of factory or self-made. Available in cast iron, black iron or stainless steel.

- Stone. They are erected from bricks, paving stones or cobblestones. Subdivided into combined and free-standing.

- Specialized. Serve exclusively for the use of a cauldron made for the preparation of several dishes.

- Universal. Designed for the use of multiple attachments, such as a smokehouse, grill, skewers.

The choice of building is determined by personal priorities and site design.

Features of brick stoves

Brick hearths are built using a special technology from a refractory material that maintains a constant shape regardless of temperature and humidity changes. Since the hearth is on the street, these qualities are at the forefront.

Classic designs are used only for cooking food in a cauldron. A recess of the corresponding shape is made under the container. There is a plate for fixing the rim, corners for the plate, inner walls through which heat is evenly transferred to the entire area of the dish. Everything else corresponds to the design of a standard hearth - a firebox, a blower, an ash pan and a chimney.

Universal complexes have separate fireboxes and outlets (plates) for each device, which can theoretically be used for cooking. To collect and remove combustion products, a common chimney is made in the form of an arch. It is expensive, difficult, but justified in terms of convenience and practicality.

Pros of using a brick structure for a cauldron

The decision to make a do-it-yourself stove for a cauldron of bricks is associated with a certain complexity in execution, but has many advantages.

- Even distribution of heat over the entire area of the bowl. Thanks to this, food is cooked much better and tastes better than in a pan or saucepan.

- Profitability. A lot of fuel is not required, it burns slowly, energy is transferred to the walls of the structure, which retain heat for a long time.

- Safety. Even during long-term cooking, the body practically does not heat up. The possibility of fire and burns is completely excluded.

- Uncomplicated construction technology, quite affordable for do-it-yourself implementation.

With the right approach to planning and construction, a structure can last for decades.

Fire safety requirements

A brick brazier is considered a safe object in terms of fire, since it does not use an open flame.

However, during its construction and operation, the following rules must be observed:

- do not place near flammable objects;

- not to be located above underground utilities, which may subsequently complicate their repair;

- do not use volatile compounds for ignition.

Do not leave objects on the stove that could catch fire from heating.

Material and tools

To build a hearth for a barbecue on the street, you need to have the following tools:

- shovel;

- Bulgarian;

- Master OK;

- mixer;

- welding machine;

- roulette;

- level;

- marker.

Materials required:

- brick red;

- fireclay brick;

- chimney pipe;

- ring plate;

- Sheet steel;

- doors for the firebox and blower;

- annealed nichrome wire;

- concrete mix;

- steel corners;

- fireclay clay.

Working with stone and metal is quite dangerous. It should be performed with goggles, gloves and a respirator.

The main stages of construction with your own hands

The process consists of the following stages:

- Planning, drawing up several options for sketches, drawings and estimates.

- Choosing a place for installation, marking.

- Purchase of materials, preparation of tools.

- Arrangement of the foundation.

- Laying out the hearth body.

- Installation of shelves, chimney, doors, accessories.

- Finishing with decorative material.

It is necessary to conduct construction in dry warm weather in order to ensure high-quality solidification of the solutions used.

First stage

The first phase of construction is the preparation of the workplace. On the territory, markings are made, vegetation, small adjacent objects are removed, communications necessary for operation are supplied - electricity, water, sewage. Packages or containers are prepared for the inevitable garbage in such cases. If necessary, a temporary or permanent shed is erected.

Erection of the foundation

The oven weighs from a ton or more, so it needs a stable base. To avoid possible distortions in the future, it is recommended to deepen the foundation below the level of soil freezing. The best option is a slab mounted on bored or screw piles. On stable soil, you can make a buried tape.

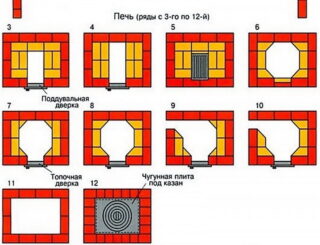

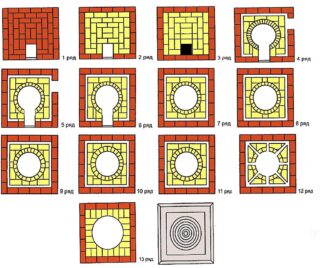

Furnace erection

The ordering is done with a height of 9-11 levels, which is considered optimal for a person of average height. During installation, a half-brick dressing is applied. The doors are suspended on a wire, which is fastened to a depth of 2-3 stones with bending along the levels. In the second row, a hole is left for the ash pan, and in 4-7 for the firebox. The grate is installed on the embedded corners. A steel sheet with a hole cut under the cauldron is installed on top.

Furnace options

The first version is a rectangular brick cabinet, where the firebox also has a rectangular shape. A more complex, but effective design, when the firebox is a cylinder lined with fireclay bricks. Such a stove ensures better cooking in a cauldron, since the bowl is heated more evenly in it, and it can be used for other purposes as well.