Railings are installed on the stairs, porch, balcony, around light summer pavilions. The purpose of the fences is convenient and safe movement, creating additional support. We should not forget about the aesthetic side of the issue. If you make solid and beautiful railings with your own hands, they will organically and effectively complement the interior, give it a certain style and presentability. This task is quite difficult, but quite feasible, provided that the technology for handling materials and the rules for their installation is observed.

Structural elements and requirements

In order to properly design and make high-quality handrails for the stairs with your own hands, you should understand their structure, size and purpose of each element.

Structurally, stair railings consist of the following parts:

- Pedestals. Support legs to ensure the stability of the entire structure. Must withstand lateral pressure of 100 kg or more. Installed at the beginning, end and at turns of marches.

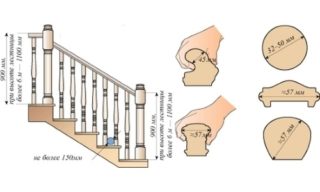

- Handrails. Longitudinal profiles along the entire length of the flights of stairs. Serves to support hands and help with lifting. The optimal height is 90-120 cm.If there are children and people of small stature in the house, a second line is made with a height of 60-80 cm.

- Balusters. They are columns on which the handrails rest. They are installed with a certain interval of 15-80 cm.

- Filling. Panels, grilles, longitudinal profiles located between pedestals and balusters.

The decision in favor of spans without fences is spectacular, fashionable, but impractical from a practical point of view. The absence of a railing is fraught with a fall from a height, injury, disability and even death.

Railing materials

According to their purpose, the stairs are divided into several categories. They can be ceremonial, spare, fire, attic, temporary and removable. Place structures inside and outside buildings. Based on this, a list of requirements and restrictions for each type of structure and their composition is formed.

The following materials can be used for the manufacture of handrails:

- Wood. The natural substance has an attractive appearance and can be easily processed with hand tools. It is easy to give blanks to any shape, to make them round, square, polygonal. Products are painted, varnished, covered with stain. Oak, spruce, pine, beech and ash are used to make railings for a wooden staircase. Carving and firing are used as decoration. Fastening of parts is carried out with glue in the grooves.

- Metal. The structures are distinguished by their high strength and durability. To make a handrail from a profile pipe with your own hands, you must have experience with a welding machine. Such structures are inexpensive but require regular corrosion protection. There are fewer problems with stainless steel and aluminum, but their price will be several times higher. An excellent solution is forging, which acts as a barrier and decoration.

- Glass. Transparent panels add lightness and airiness to the spans, while effectively protecting people from falling between the balusters. The production uses tempered and laminated glass, monolithic and honeycomb polycarbonate. Sheets are inserted into frames or fixed in brackets with bolts. Panels can be transparent, colored, matte and stained glass.You can even make racks and railings out of glass, but you have to work hard to give them the desired configuration.

- Plastic. Polymer structures are corrosion resistant, lightweight, durable and biologically inert. A hand-held PVC tape is put on a steel frame, decorative polyurethane or foam balusters are attached to a metal or wooden rod.

- Concrete. The products are highly durable and resistant to environmental conditions. They are mainly installed outdoors, but fit well into classic and industrial style rooms. Bollards and balusters are cast in molds and then fixed in place with anchor bolts.

- Combined. The combination of materials of different properties allows you to achieve a combination of the required qualities in the building envelope. If you assemble a handrail for a staircase made of wood with your own hands, the racks can be made of metal, the handrails are made of plastic, and the filling is made of glass.

When planning construction, it is necessary to provide for the type of design of the railings so that they correspond to the general design solution of the room.

Necessary tools and materials for work

To make a handrail from wood, concrete or metal with your own hands, in most cases, there are enough devices and devices that are in the pantry of every homeowner.

The extended universal set includes the following tools:

- cutter;

- hacksaw;

- chisels, incisors;

- grinder, drill with drills and mixer, belt grinder, perforator;

- tape measure, square, level;

- hammer, mallet;

- construction hair dryer;

- paint brush;

- pencil.

The content and size of the list of materials depends on the type and style of the future design.

To build a combined railings you will need:

- impregnation, primer, antiseptic;

- sandpaper;

- paint, stain;

- hydrophobic agent, fire retardant;

- hardware (bolts, nails, screws, anchors);

- sandpaper;

- crushed stone, sand and cement for concrete preparation;

- steel profile;

- improvised materials (boards, logs, firewood, old pipes and fittings).

You should consider your own safety issues. You need to work in goggles and gloves, use safety devices at a height.

Work order

Construction begins with competent and accurate planning.

Several sketches are made, then a detailed drawing is drawn up based on the best option. It focuses on such aspects as ease of movement, safety and conformity with the design of the surrounding interior.

A step-by-step instruction is compiled, which indicates the sequence of all actions and their detailed description.

The order of work in the manufacture of metal structures

- Marking. The locations for the installation of supporting and supporting structures are outlined. Control points are applied relative to the centers of the products or along their outer contours.

- Production of pedestals and balusters in accordance with the project. It should be borne in mind that the supporting products should be 2-3 times thicker than the intermediate ones. When casting concrete blanks, it is advisable to install mortgages for the convenience of subsequent fastening to the base.

- Steel frame assembly. It is done in cases where the iron frame serves as the basis for attaching the polymer or the minimalism style is used in the project. First of all, the skeleton is assembled in the form of a parallelogram. For this, a profile pipe or strips with a width of 5-8 cm and a thickness of 4-8 mm are used. For the convenience of joining, parts are trimmed at the corners. Welding is done pointwise, after checking the quality of the result, the final seam is made.

- Attaching balusters. The workpieces are applied to the frame and a cutting line is drawn on them.After that, the excess metal is cut off with a grinder. The joint is cleaned and the balusters are welded to the frame.

- Attachment to the lower corners of the frame of posts with base plates. They are needed to attach the railing to the steps. Holes are drilled in the plate corresponding to the outer diameter of the fasteners.

- The finished structure is cleaned of sagging, scale and rust. It is treated with an anti-corrosion agent and painted. It is better to do all this on a separate site so as not to burn the stairs with sparks and not to splash paint.

- The railings are screwed into place. Final alignment and fixation is performed.

- Attachment to the handrail lining. For this, a bar, a handrail or a ready-made PVC profile is used.

Over time or immediately, you can fill the gaps between the balusters with glass, panels, gratings or forging. This will give the design an even more sophisticated and sophisticated look.

The assembly of wooden structures is carried out in a slightly different way. The frame is not done, pedestals and balusters are installed directly on the steps. The spikes for the grooves are cut at an appropriate angle, after which the handrail is mounted on the supports. Pre-docking parts are abundantly greased with wood glue. Excess leaks are removed immediately. In conclusion, preventive treatment and decoration of the structure is carried out.