Noise in an apartment is an unpleasant phenomenon that interferes with normal sleep and rest. This factor is annoying to humans. Soundproofing the floor in addition to wall decoration in a multi-storey building will help get rid of the problem. However, before starting the work, you need to consider the methods for carrying them out, as well as choose the right material.

Ways to implement noise isolation

No insulator can completely eliminate noise in an ordinary apartment. However, modern materials can significantly reduce its intensity.

Soft floor

Soundproofing the floor in the apartment can be done with soft floor coverings. These include carpet, felt-based linoleum. The presented materials are easy to install, relatively inexpensive, and have excellent decorative properties. The only drawback of this method of sound insulation is that it cannot be used when laying underfloor heating systems.

Using soundproofing pads

Soundproofing of the floor is carried out with special substrates. They are used for the installation of hard floor coverings. Cork materials, foamed polyethylene are more often used. Substrates reduce noise levels and eliminate minor irregularities in the subfloor. Choose a product depending on the type of flooring material, its density and weight.

Floating floor

With a floating floor, the intensity of impact noise can be reduced. In this case, the floor material and the floor are not connected in any way. This prevents the transmission of sound vibrations. This design is the most efficient.

There are several types of floating floor: concrete or dry screed, prefabricated structure. In any case, this method of insulation is multilayer.

Modern materials

To protect the house from unnecessary noise, you can use roll, slab products and liquid formulations, which crystallize and create an insulating layer. Wood-based materials are no less popular.

Polymer and plastic

The group of polymeric products for soundproofing the floor under the screed includes polystyrene, reflectors, liquid polymers. These materials have the following features:

- Styrofoam. As an insulator, it is better to use the most dense varieties. It will not break or shrink. For effective noise absorption, slabs with a thickness of 5 cm or more are required. Additionally, the foam provides insulation of the base, protects against moisture. It is characterized by a long service life. Extruded polystyrene foam copes best with sound insulation.

- Penoplex. The material is characterized by high strength and high density. It does not deform even under high mechanical stress. Plates are not susceptible to corrosion and damage by rodents, they are resistant to moisture, the development of fungi, mold. Penoplex is easy to install. In addition to noise suppression, the slabs provide thermal insulation.

- Liquid polymers. They are applied to the floor surface with a layer 3 cm thick.After curing, the material has a bumpy surface, therefore, the base is leveled before laying the floor covering.

- Reflective. Special materials for noise control.

The choice of material depends on the type of noise and the requirements of the room.

Mineral

Sound insulation on the floor is made of mineral wool, expanded clay or sand, cement compositions. The first option is used more often than the others. Cotton wool is produced in rolls or mats. It can be used for any kind of substrate. A crate is required for laying the product. Mineral wool has a small mass, is affordable, even an inexperienced master can handle the installation.

This insulator does not contain formaldehyde or other chemicals that are harmful to health. However, when laying the product, you need to take care of reliable waterproofing. Long-term exposure to moisture leads to the gradual destruction of the material.

Expanded clay is more used as insulation. Clay gravel is used to reduce the noise level. Moreover, its fraction should not be less than 4 cm. Sand also absorbs unnecessary sounds well. However, this material makes the base heavier. For isolation, special cement mortars are also used, which contain polymer additives.

Wood-shaving

You can soundproof the floor with plywood, sawdust or wood chip boards. The most demanded material is cork backing. It is laid on a concrete screed and on wooden logs. The material is environmentally friendly, hypoallergenic. The advantage of sheets is that with a thickness of 1 cm, they reduce the noise level by 20-22 dB.

Silicate

Glass wool contains synthetic fibers that are randomly arranged. The material does not burn, is lightweight. The disadvantage of such an insulator is that it must be placed in protective clothing, gloves and goggles. A respirator must be used to protect the respiratory tract.

It is allowed to install glass wool even on metal pipes, since it does not cause corrosion.

The choice of sound insulator depending on the floor covering

The choice of soundproofing material depends on what kind of flooring will be used for the finishing.

Laminate

Sound insulation under the laminate is laid taking into account its properties. Since the product has a dense structure, unnecessary sounds occur even when walking on the floor. The problem can be avoided by using such substrates:

- polyethylene foam;

- cork;

- expanded polystyrene;

- based on wood.

The thickness of the insulating layer ranges from 2 to 7 mm. The more massive the laminate planks, the more backing is required. Sound insulation should provide a perfectly flat base.

Parquet

Each package of material indicates on which substrate it should be laid. For parquet, artificial or natural products are used. The first group includes polyethylene foam, polystyrene and bitumen. Needles or leaf cork are popular among natural substrates. When choosing an insulator, take into account the following features:

- thickness no more than 3 mm;

- long service life.

You need to be careful with the choice of artificial materials, as they provoke rotting processes in the wood.

Linoleum

Soundproofing material for linoleum must be strong enough to withstand mechanical stress, resistant to moisture. The best option is a cork backing. Sound absorbing membranes are also popular.

Wood

When choosing an insulator, preference should be given to materials that provide a high level of noise absorption.It is better to use fibrous mats: mineral or stone wool, silicate products. If the floor is equipped with logs, additional protection against unnecessary sounds can be achieved using a rough base made of plywood or OSB. The maximum result will be obtained by combining insulating materials.

The main requirement for the material is resistance to moisture, ensuring good air exchange. To reduce the noise level, felt is stuffed to the wooden beams.

Tile

Tiles are most often laid in kitchens and bathrooms, so the sound insulator must be resistant to moisture. In this case, expanded clay or extruded polystyrene foam is suitable. After installation, the screed must be poured.

Shumoplast or zvukoizol do not require additional protection from moisture, since they are processed at the production stage.

Do-it-yourself floor soundproofing

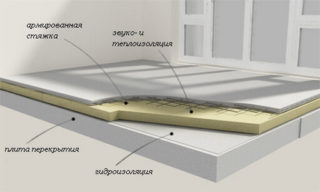

To put soundproofing under a laminate or other floor covering, it is necessary to follow the sequence of work, depending on the chosen installation method. If you plan to install a wet screed, the instruction provides for the following stages of work:

- Preparation of the base. It is cleaned of debris and dust. There should be no furniture in the room.

- Installing a damper tape. Its width exceeds the height of the screed.

- Waterproofing flooring. The film should go over the walls. The canvases are overlapped between themselves, and the joints are connected with construction tape. At the same stage, a sound insulator is laid over the entire surface of the base.

- Reinforcing mesh laying.

- Installation of lighthouses. They are equipped with metal profiles.

- Pouring cement mortar with polymer additives that provide sound insulation. The total thickness of the screed is 4 cm. After that, the solution is leveled with a rule. After its hardening, the surface is polished.

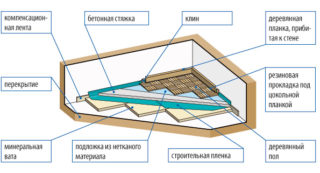

Insulation of wooden floors is carried out in a slightly different way. To avoid the appearance of noise bridges, the material is laid between the floor beam and the joists. A sound insulator is mounted throughout the space created by the beams. The second layer is laid on the logs. In this case, a foamed polymer or synthetic felt is used. The latter option is costly. Last of all, screw the subfloor from OSB.