Heating units can heat the building for a long time after one fuel filling. Four to five kilograms of firewood do not burn, but smolder and emit gas, which additionally burns and gives heat. House owners build a long-burning stove with their own hands, drawings of the most effective model can be found on the Internet, ordered by specialists in the installation of heating equipment.

- Description and types of long burning furnaces

- Classic oven

- Shaft furnace

- Hearth furnace

- Gas generating furnaces

- Design features and principle of operation

- Materials and tools

- Calculation of basic parameters

- Furnace size

- Material thickness

- Steel pancake parameters

- Outlet pipe parameters

- Dimensions of the air supply pipe

- Preparation for work

- DIY oven

- Bubafonya stove from a gas cylinder

- Long burning brick oven

- How to upgrade the oven

- Modernization of the "bubafonya" oven

- Modernization of a brick oven

- Features of operation

Description and types of long burning furnaces

The unit is convenient to use, because after loading, you may not open the furnace for a long time. In the process of burning wood or coal, combustible gas is released, which is collected in the chamber, where it burns out and releases energy.

Such devices are used in private houses, summer cottages, garages, enterprises.

In terms of functionality, the stoves are divided into equipment for heating, cooking, combined options are used. The material is metal, cast iron, brick. For year-round use, it is better to choose a brick hearth of combined action. A homemade bubafonya stove from a gas cylinder would be a good option.

Classic oven

The complex design assumes the presence of an internal coal combustion chamber. It is equipped with a chamber connected to the hood for the afterburning of the emitted gases.

The fuel is ignited from below, the gases enter the bell and burn out. The classic manifests itself in pushing combustible gases through a mass of fuel into a chamber where air is supplied. These types include stoves: buleryan, Butakov's stove.

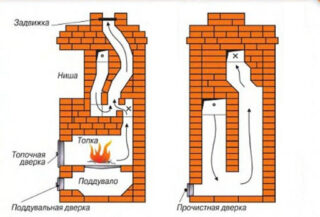

Shaft furnace

The composition includes:

- kokoshnik for loading the charge, exhausting gases;

- oven shaft;

- bugle;

- lance for gas supply.

The equipment has a high efficiency ratio and great productivity.

Hearth furnace

In it, fuel is ignited from above, the fire moves down. Air is supplied under the burnt layer through special channels. The simple and effective design is developed in a variety of models that are easy to make with your own hands.

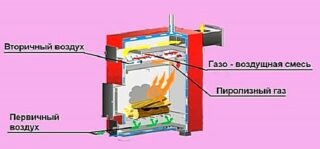

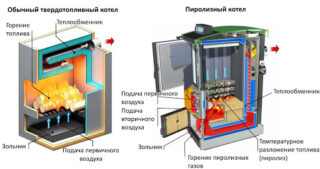

Gas generating furnaces

Provides for slow combustion of gases separated on the basis of pyrolysis. Wood fuel burns out under the influence of heat and a small amount of oxygen, and flammable gases are emitted. The unit must have a heat exchanger. Suitable for heating with one or two circuits.

Design features and principle of operation

The advantages of the equipment are high efficiency, lack of complex automation, energy independence, safety in comparison with boilers using gas and liquid fuel. Pyrolysis units give a useful figure of 90%. Long-burning furnaces show a result of 75 - 80% due to the interaction of the body with the water pipes of the heat exchanger.

The disadvantage is the high cost of finished units.

Wood fuel is put into the firebox, which burns out quickly.A period of intense combustion (1 hour) is needed to heat the boiler, chimney. Then the stove is loaded to the top with fuel, the door is tightly closed, the gate valve is closed to minimize the air supply and draft. Under these conditions, good combustion is ensured with the release of flammable gas.

A smart stove runs on coal or brown coal, peat, you can use firewood of various species and waste from wood processing. Granules and briquettes are made from sawdust, shavings. They use modern types in the form of pallets and eurowoods. There are boilers converted for liquid fuel.

Materials and tools

They use iron barrels, gas cylinders (50 - 100 liters). The air supply channel is made of a steel pipe, the smoke exhaust channel is made of iron or ceramic. For the cover, take sheet steel 3 - 5 mm. Prepare the door and hinges for it. The water circuit is made of sheet iron and two threaded pipes.

For work you need welding, grinder, drill, file, hammer, anvil, measuring tool.

Calculation of basic parameters

Indicators are chosen for the effective use of the firewood loading area, ash collection chamber. The parameters determine that the area of afterburning of the evolved gases works effectively. The correct metal thickness is selected for the case in order to extend the service life.

Furnace size

The height of the furnace is made no more than 1.0 m, the operating time of the equipment depends on this indicator. It is inconvenient to load briquettes into a tall structure, it does not provide effective traction, and combustion dies out.

The diameter is selected following a proportionality ratio from 1: 3 to 1: 5 (height, section, respectively). The furnace with a diameter of about 0.3 m works optimally. Narrow chambers are not recommended, since the air from them is drawn into the pipe, which reduces the power of the homemade product.

Material thickness

The criterion is important, since thin metal of the case will burn out faster. Choose steel for the furnace walls not less than 5 mm thick. This parameter is especially important for the boiler version with a water heat exchanger.

Thin walls up to 5 mm contribute to a loss of power, a drop in temperature, and a decrease in the intensity of gas afterburning. As a result, the generation of heat decreases.

Steel pancake parameters

The iron element simultaneously serves as a partition and a heating platform for the ignition of pyrolysis gases. The optimal size is when the gap from the outer edge to the inner surface of the unit is 5% of the total diameter.

Outlet pipe parameters

More often they are made of a steel pipe of circular cross-section for removal of products of combustion of fuel and gases, removal of condensate. Avoid using square sections to reduce soot build-up.

The diameter of the outlet pipe is taken at the level of 80 - 100 mm.

Dimensions of the air supply pipe

For a homemade stove design, a metal pipe is used, the diameter of which exceeds 50 mm. Most often they put 70 - 80 mm. The pipe is welded in the middle of the steel circle, matching with its hole. As a result, an element is obtained, which is called a piston.

Preparation for work

Pre-cut iron blanks according to the sketch, prepare the details of the handles, grates. A stand is made of brick, the section of which is 30 cm larger than the body. A metal lining is made by welding corners or rods to the cylinder.

The stove is placed no closer than 1.0 m to the wall, while taking into account the need for thermal insulation of the case.

DIY oven

Use any steel container with the required wall thickness. Metal is used most often, sometimes craftsmen build ovens from bricks. Iron structures have the advantage that they can be rearranged as needed.

Bubafonya stove from a gas cylinder

The top of the container is cut off with a grinder at the point where the walls of the cylinder are rounded, the part is used as a cover. A strip of iron is welded to the cut for its stability.

For the pressure piston, a circle is cut out of steel so that it can pass inside the cylinder, a 5 cm hole is formed in the middle. The supply air pipe is welded to the hole. A channel is welded to the reverse side crosswise. A chimney is installed at the top and on the side, the cut seams are cleaned with a grinder. A do-it-yourself long-burning stove from a gas cylinder is ready.

Long burning brick oven

Such a furnace looks the most advantageous, but it requires a lot of labor during construction and more time.

A solid foundation is built regardless of the base of the house; its dimensions exceed the dimensions of the stove by 20 cm on each side. A sand-gravel bedding is made under the sole, a layer of roofing material is laid.

After concreting, you can put the oven on for 28 days. The top of the foundation is isolated from the masonry with roofing material in 3 layers, a heat-resistant coating of asbestos and glass-ceramic materials is placed.

The layout of the bricks in each row is needed to ensure the effective work of the structure. Ordering drawings can be found on the Internet, where the method of laying each tier is indicated.

Gases inside move not only vertically, but also pass horizontally. Correct laying of rows increases the plane of contact between smoke and bricks, and increases the return of thermal energy.

How to upgrade the oven

Modernization is about usability. An iron stove weighs a lot (150 - 160 kg), and to clean it from ash, it must be turned over. The improvement consists in the installation of doors through which combustion residues can be removed.

Modernization of the "bubafonya" oven

The peculiarity of the unit is the absence of gaps and tightness, therefore, when installing the doors, insulation must be done. First, iron sides are welded in the opening, then heat-resistant seals are used.

The cruciform sections of the channel under the piston base are replaced with metal plates to improve air flow. So the flow will not swirl, but will be rhythmically distributed in the furnace chamber.

Modernization of a brick oven

A triangular stove is made to be installed in the corner of the room. Less brick will be spent on masonry, which will save the owner's money.

The second option is to install a dividing flap for switching between summer and winter use.

Features of operation

Reduce the amount of air supplied to reduce the rate at which the wood burns out. Condensation can be avoided by making fewer turns of the chimney duct.

The moisture content of the loaded fuel should not exceed 25%. Do not open the door during combustion to keep carbon monoxide out of the room.

Twice a month it is necessary to heat the unit at maximum mode in order to burn off slag deposits on the inner walls. The efficiency of the stove will be higher if you use large-sized firewood.

Cool oven, and neatly made, and everything is correct

But what about the stoves approved by Gosstroy? And what about the Grum-Grzhimailo ovens? After all, before gasification, people lived with stoves and there was no such problem with heating.

the oven is great