Arranging shelving in a cellar with your own hands is a simple solution for homely owners. Even a novice carpenter can handle the manufacture of structures for storing pickles and stocks for the winter. For the correct and convenient organization of the space, use the ideas presented and the step-by-step guide.

Options for shelves in the cellar

Various materials are suitable for creating shelves in the basement with your own hands. The stability and durability of the structure depends on the temperature and humidity in the room. For example, wood is a moody, albeit durable material. If there is dampness in the cellar, there is a risk of gradual destruction of the structure. The loading capacity of the shelves depends on the type of product.

- Prefabricated - this option has a strong frame and a long service life. Several types of materials can be used in the design. For example, a metal profile is used for the support, and boards for the base.

- Collapsible - compared to the previous version, these models are endowed with significant advantages. You can make a rack from any material. The structure is disassembled and assembled to disinfect the premises and dry the equipment.

- Radius - are round and with rounded edges. As a rule, they are placed at the corners of the main structure. This allows you to rationally use the free space by installing boxes for storing vegetables on them.

- Monolithic - a budget option for the efficient operation of the cellar. It is considered simple and inexpensive to perform, which is a big plus for home craftsmen.

To conveniently equip a basement for storing agricultural products, it is recommended to combine shelf materials and place racks in different areas of the room.

Material for the manufacture of shelves

The shelves in the basement are a salvation for thrifty owners who annually prepare pickles and canned fruits for the whole family. It is unrealistic to store all this wealth at home or in an apartment, so it is necessary to equip racks in the cellar or garage. What material to choose for their manufacture is up to the owner to decide.

Wood

The main enemy of lumber is high humidity. Wood rots and deforms when exposed to damp air. In the absence of high-quality ventilation in the basement, the destruction process occurs faster.

However, wooden shelving has its advantages:

- easy installation;

- minimum of tools;

- a novice carpenter will cope with the work;

- inexpensive material.

In order to avoid damage to the lumber structure, it is recommended to carry out treatment with antiseptics annually.

Plywood or plate

The materials have a low load-bearing capacity. Therefore, in the process of manufacturing such racks, the sheets are additionally strengthened. However, it is still recommended to use similar shelves for small cans.

Metal profile

Metal structures are distinguished by their reliability and long service life. In addition, such elements can be easily removed for drying. But the profile has drawbacks - at high humidity, rust appears. To use the structure longer, it is necessary to treat the surfaces with anti-corrosion agents.

Concrete

Concrete shelving is a great choice for arranging storage. Items of any weight can be placed on the shelves, since the structure is not subject to deformation. Such structures in the basement have been standing for centuries - it is enough to ventilate the room every year.

The downside of concrete is the time consuming process and the cost of the material.

Brick

In the manufacture of brick shelves, it is necessary to adhere to the masonry technology used in the construction of buildings. The advantages are long service life, reliability and easy maintenance. The disadvantages include the need for an assistant and the availability of appropriate skills.

Slate

This material is rarely used for making shelves in the cellar. As a rule, separate fragments are cut out of it. It is possible to make a rack in a cellar from flat slate, but it will not withstand a high load. The only option is to strengthen it with fastening corners along the entire perimeter in 0.5 meter increments.

Plastic

Plastic flooring is not subject to rust and deformation. Lightweight material with relative strength. The disadvantage is that it is unlikely to withstand a large number of three-liter cans of tomatoes.

Shelving instructions

Despite the large selection of materials for the manufacture of shelves, wood remains traditional. Below are step-by-step instructions on how to create PP racks and planks.

Technology

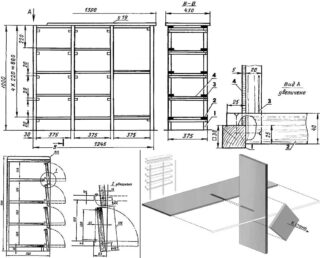

Wood structures are slightly more expensive than metal profiles. To save the budget, drawings are first made with exact dimensions before manufacturing, and then materials are purchased.

The scheme for making shelves in the cellar with your own hands from boards is as follows:

- Make notes on the diagram where the structure will be located. The parameters are selected individually - it depends on the free area. Treat lumber with antiseptic agents to protect against fungus.

- Secure the vertical planks along the entire length of the rack to form the base for the decking.

- Attach cross members to the bars to support the shelves. Process and fix the jumpers with self-tapping screws or bolted connections.

- Spread the boards out to the full length of the structure - these are the shelves for storing supplies for the winter.

- Close the gaps with narrow pieces. Metal corners can be used as an additional attachment.

The reliability and strength of the sections will be given by treatment with a stain or paint and varnish. These works are aimed at preserving the aesthetic structure of the wood. It is recommended to renew the coverage once a year.

Rack made of polypropylene pipes

Polypropylene pipes are a modern material that is actively used in summer cottages. Due to its composition, it is not afraid of temperature extremes, exposure to moisture, and is also easy to use.

The only difficulty lies in the possible lack of starting materials and special equipment. However, the tools can be rented, and the material can be purchased at a sale or at a stock price.

Algorithm for creating shelves in the basement for cans from a polypropylene pipe:

- Take measurements of future sections. Pipe # 32 is suitable for manufacturing. As connections for external fasteners are used - "tees", internal - "crosses".

- Fix the required number of pipes.

- Install the structure.

- The final step is laying the flooring. Any material is suitable here - plastic, plywood, wood, etc. It is noteworthy that polypropylene is organically combined with PVC window sills.

Pipe sections serve for many years, and it takes 2-3 hours to make them. At the same time, the design is not afraid of flooding and is easy to maintain. To reduce your financial burden, order recyclable materials.

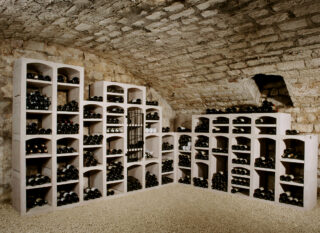

Organization of storage space

To increase the shelf life of vegetables and fruits and ensure the convenience of using the basement, it is recommended to arrange the space. Most of the premises are occupied by racks, on which cans and products are placed that do not require separate containers for storage. Install wide shelves near the entrance on one side, and boxes for vegetables and fruits on the other. It is better to make sections for the basement up to the ceiling in order to rationally use the space.

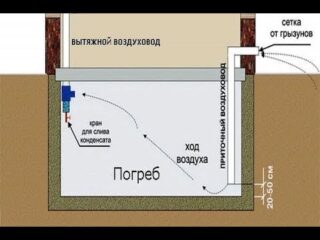

A well-made ventilation system in the cellar increases the service life of not only products, but also structures. Due to the constant air exchange in the room, the humidity will be within the normal range. This will provide protection against mold and rust formation.