A well-equipped storage system from the shelves in the barn saves space and helps to store a large number of things. The manufacturing technology is simple, so anyone can mount the rack in the barn with their own hands. There are many options for fixing shelves, with different materials used, so there is always a choice.

Materials for making

Most often, lumber of various sections is used, but iron welded structures are possible. New building materials are not necessarily used, you can take improvised racks, plywood that has already been in use, unedged board.

Requirements for materials:

- strength, integrity;

- ability to withstand low temperatures in winter;

- ease of processing, assembly.

Materials work well in combination with each other. Wooden shelves can be placed on the metal frame. Planks on the walls are placed on metal brackets. Wood and metal are painted with sewn compounds, and before installation, they are treated with anti-corrosion agents, antiseptics, and agents against the rapid fire of wood.

Wooden shelving

Models made of wood are distinguished by their low weight, high strength indicators. Wood works well in compression and resists bending and torsional forces. It is better to make shelves in a barn from hard wood, although they are difficult to cut and drill. Such varieties hold self-tapping screws well, the fasteners in them do not loosen.

Benefits of wood:

- low cost;

- simple and fast assembly;

- convenient to service;

- aesthetic appeal, environmental friendliness;

- long service life with regular repair and processing.

The disadvantage is susceptibility to rotting, the wood is spoiled by bugs, as a result, dust is obtained. But such complexities are easily defeated by preprocessing. A simple way is to impregnate wood with drying oil heated to + 60 ° C for 2 times.

Metal shelves

The perfect solution for heavy and bulky items. Each shelf on the support can support 100 - 120 kg, the reinforced structure with stiffeners can easily hold up to 250 kg.

The material is also inexpensive, you can use old corners, channels, brands. Iron pipes of round, rectangular cross-section are suitable. It is easier to join a profiled pipe with rectangular walls.

Metal advantages:

- simple assembly using welding equipment;

- durability, stability, strength;

- unlimited number of tiers;

- the possibility of re-equipment, adding length, height.

If movable rollers are welded to the bottom of the racks, the racks can be moved to another place in the shed. At the same time, there should not be too heavy objects on them.

The metal is treated with anti-rust agents, then painted with oil, acrylic, latex compounds, and varnished.

Tools for the job

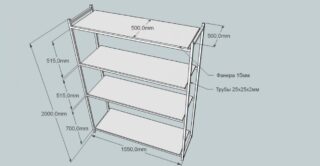

For the manufacture of shelves from chipboard plates on a wooden frame, panels with a thickness of at least 20 mm are taken. For racks and crossbars, lumber (timber) with a section of 70 x 60 mm is used. The elements of the rack are connected with self-tapping screws (80 - 100 mm frame, 40 mm shelves); steel overhead corners are used for stability.

You will need tools:

- circular saw, jigsaw, wood saw;

- building level, tape measure, pencil, carpentry square;

- screwdriver, drill, pliers, screwdriver, knife;

- machine for fastening emery.

For painting, choose pentaphthalic enamels, latex or acrylic compounds. Get an antiseptic and a protective primer against moisture. Emery paper is used in size 120, 200.

Different designs

The construction and assembly scheme is chosen depending on the storage requirements. The design provides for open shelves, racks, the space is designed in the form of plug-in cabinets, drawers are used.

In the rack layout, an area is placed for storing tools with long handles, for example, shovels, a rake - wall clamps are mounted in this area. In the lower part, a niche is left for storing car tires, large items.

Shelves are made in different heights depending on the needs. Separate hanging shelves are also placed at a level that is convenient for use.

Wall options

Hanging structures are placed directly above the workbench, or installed under the roof of the shed. They adapt the shelves in the utility block for large items, or store all kinds of trifles.

Materials used:

- bars, galvanized and steel profiles for strapping;

- for horizontal surfaces - boards, plywood, sheet steel and their combinations.

The wall support consists of an oblique strip and two pieces at right angles. Such elements are made of wood or metal. Steel stops are welded and fixed to the wall with anchors. On jibs, plywood or a board can be attached without strapping from a bar.

Hanging shelves made entirely of wood are easier to make, since no welding equipment is needed. The material is dense wood. For not too loaded structures, pine is used, spruce, which are cheaper, are easier to process.

Multilevel shelving

The sections are made free-standing or the racks are fixed to the wall. In the first case, a full-fledged frame is assembled that can be moved. The vertical elements are interconnected by transverse crossbars, on which boards or plywood are subsequently attached.

In the second case, rectangular sidewalls are made from sheer racks and crossbars. These blanks are mounted to the wall using dowels, anchors. Shelves are placed between them, the ends of which are supported on the transverse rails of the sidewalls. This rack cannot be moved if necessary.

Shelves occupy the plane of a whole wall or part of it, but many items can be placed on such a structure. The sections look organically in any shed, visually do not overload the space. The gap from the floor surface to the first shelf is the largest in size to accommodate heavy and large things.

Manufacturing process

Mark the position of the racks on the wall, floor and ceiling. Then the required lengths are cut from the bar.

The further process includes operations:

- Wall posts are fixed to the wall, ceiling and floor, trying to maintain verticality. They are attached to the wall with anchors; metal corners are used for fixing on the floor and ceiling.

- The racks, which are spaced from the wall, are fixed only to the ceiling and the floor with corners.

- The distance for the crossbars is measured between the posts. They are cut out of the timber and fastened to the end with self-tapping screws. You can use corners.

Plywood is cut according to the dimensions of the spans, squares are cut out in the corners for installation on the frame. They are fixed to wooden beams with self-tapping screws, screws or nails.

Choosing a location

Shelves take up less space than racks, so they are installed in different places where you need access to tools and hardware to perform work. The height from the table or workbench is chosen so that it is convenient to reach with an outstretched hand.

Racks are best placed against a free wall or part of it.The design assumes a height from floor to ceiling, so in this area of the shed there should be no other pieces of furniture, fences, cabinets. If the structures of shelves or racks are in the darkened part, then lighting is made to see the stored items.

Successful examples

You can arrange a warehouse for little-used items under the ceiling of the barn. Hinged shelves are made around the perimeter in accessible places on the wall. To use you need to have a small stepladder. Storage of long items, such as fishing rods, is organized under the ceiling. The bearing capacity of such shelves is chosen depending on the weight of the items.

The idea of a corner shelving unit is quite relevant if there is little space in the shed. For manufacturing, three racks are used, one of which is placed in the corner, and the others are fixed to adjacent walls. The shelves will be triangular in shape. Small things and tools are kept here.