The degree of sound insulation of the door depends on the properties of the leaf material and the finishing layer. The noise should remain on the street or in the adjacent room for the person to feel comfortable. Soundproofing doors together with the installation of false gaskets helps to reduce the penetration of sounds by 30 - 40%, but the work must be done in compliance with the technology. Improper shielding will only increase acoustic and impact noise.

Reasons for poor sound insulation of doors

If the door leaf is made of wood, the sound is retained by the massive of the leaf, since wood has a low sound conductivity. Hollow canvases, made of a frame with plywood or fiberboard sheathing, transmit noise more. Metal planes almost do not block the background noise.

There should be a strip under the canvas that reduces the ingress of external sounds, therefore, noise insulation of interior doors without a threshold is performed especially carefully. Special tapes made of elastic materials are used.

Impact sound is transmitted to the door unit from moving objects, steps, striking walls or floors. The canvas perceives din through the air, humming in ventilation ducts, mines, reflects echoes in empty rooms. An unprotected door does not stop loud music and voices, dog barking.

Features of soundproofing door leaves

A simple and common method is door padding with soft insulation padding. The amount of protection in this case depends on the thickness of the layer. If the surface is upholstered with chipboard sheets or wood, the change in the weight of the sash is taken into account and additional awnings are installed, the box is strengthened.

The option of installing a double door with a vestibule design is allowed. The air gap will reduce the level of unwanted sound. Seals are used between the sash and the lute so that a protrusion is obtained that covers the gap for the passage of sound and cold.

In the finished iron blocks, there is already insulation, which is also considered as soundproofing the front door. Budget versions of canvases are produced hollow, therefore, they require the installation of a protective layer.

The double sheet metal structure can amplify the sound as it acts like a drum.

Material selection

Lightweight materials are used that tightly fill the gaps between the stiffeners inside the panel.

Insulator properties to pay attention to:

- low rate of sound conduction;

- light weight;

- incombustibility;

- resistance to temperature extremes (for entrance groups).

Sound insulating material should have a fine-mesh structure, randomly located threads to absorb sound bursts from outside. The cost of the insulating layer and the presence of an adhesive coating on its surface matter.

Artificial leather is used as upholstery; it can be on a natural or synthetic basis. They use lining, MDF panels, plastic. The material must be resistant to abrasion, weathering and degradation.

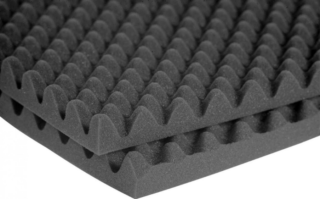

Foam rubber

Soft porous material reduces the energy of the sound wave, partially absorbs it. Foam rubber will help insulate the entrance door and the indoor unit.

Rules for working with the material:

- During installation, it is not recommended to deform the slab, crush it, push it into an unsuitable space.

- The material is attached to the base with adhesive double-sided tape or special glue is used to prevent the insulating panel from dropping over time.

- The insulation is protected from external influences by the casing so that it does not collapse.

Foam rubber is supplied with rectangular mats, the thickness varies from 10 to 20 cm. Plates are produced with a wavy or even surface.

The disadvantages include the ability to become saturated with dust. Foam rubber serves as a refuge for harmful domestic insects.

Sintepon

An insulator belongs to the group of non-woven materials in the form of threads or fibers, combined with each other in a wide web. Sintepon is a collective category of unnatural heaters with soundproofing qualities.

Different raw materials are taken for production:

- Polyester yarns. Wool or cotton fibers are added to them. The material contains several layers that are parallel to each other. The mechanized process allows you to join the threads in a multidirectional method, which increases the quality.

- Secondary raw materials. Use household plastic, bags, disposable tableware to reduce the cost. Such material does not withstand numerous mechanical influences (washing), but its use is quite appropriate for soundproofing doors.

The synthetic winterizer is resistant to moisture, does not cause allergies, elastic, durable.

Mineral wool

The material is obtained by melting metal slag and rocks. The first option deteriorates quickly, while the second is a good quality non-flammable layer. Mineral wool differs in the structure of the fibers, depending on the characteristics of the raw materials.

Distinguish material by structure:

- horizontal layers;

- vertical layers;

- with spatial fibers;

- with corrugated threads.

The fibers are connected to each other using formaldehyde resins, so such layers require mandatory sheathing on the outside. Wool made from ceramic refractory fibers or fiberglass is considered less dangerous.

Mineral wool soundproofing material must be protected from the formation of condensation, since getting wet reduces its properties.

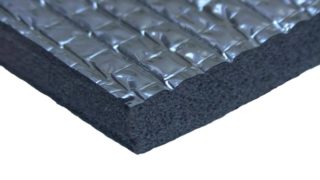

Izolon

It is a foamed polyethylene foam. The production process includes spraying the mixture with hydrocarbon gas, propane, as a result of solidification, elastic panels are obtained. They are sold in the form of bundles, rolled cloth, and shells.

Isolon qualities:

- high soundproof characteristics;

- strength;

- ease of installation;

- small thickness, light weight.

Non-stitched and stitched material is produced. The output parameters for density and thickness depend on the use of technological modifiers. The surface of the sheets is even, inside there are closed small pores. Differs in environmental safety, does not emit harmful components into the surrounding space. Wear resistance is determined by the amount of deformation under a point effect - the smaller the punching shear, the higher the indicator.

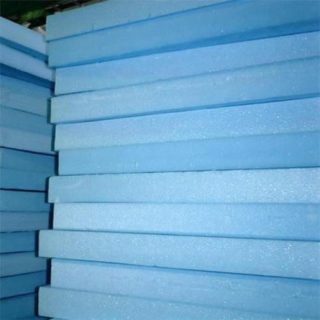

Polystyrene

The insulator has a porous structure, which is obtained by melting polystyrene grains, the holes are filled with natural gas. The fine-mesh structure provides good isolation from sounds and hum. The material can withstand sudden changes in temperature and wet conditions. The insulator simultaneously acts as a heater.

Extruded polystyrene is produced by passing and extruding from a unit, where it is subjected to mechanical and thermal pressure.The panels have a closed-cell structure, the pore diameter ranges from 0.1 to 0.25 mm.

The extrusion version has an increased degree of ignition, while carbon dioxide is added to conventional polystyrene with fire-fighting characteristics.

Styrofoam

Created by steaming plastic microparticles. The main volume in the mass of the material is occupied by gas, so a low-density insulator is obtained. The sound is retained in the structure of the foam, since the air cells extinguish it, and noise is distributed along their walls in an insignificant volume.

By the type of raw material, the types of foam are distinguished:

- polyurethane;

- polyvinyl chloride;

- urea-formaldehyde;

- phenol-formaldehyde;

- polystyrene.

When soundproofing a door with polystyrene foam, protection from environmental influences is required, since the layer deteriorates from contact with dichloroethane, benzene, acetone and their vapors.

Fungi and algae do not grow on the surface of the foam, the insulating layer is not of interest to rodents.

The material is cut with a hacksaw or hot wire, but the work is done in ventilated areas.

Factors affecting door sound insulation

Sound absorption depends on the structure of the frame and door leaf. Old technologies of the frame fabric do not contribute to the containment of sound, and some structures resonate, so noise bursts only increase. In modern doors, the interior space is filled with cardboard according to the principle of a honeycomb, the effect is better than that of wood.

Sound insulation of an entrance metal door requires attention, since steel has a high conductivity of sound waves. If only a frame is made of iron and filled with double glazing or a double-glazed unit with several chambers, the noise transmission will be significantly reduced.

Required tools and materials

The list of materials depends on the type of insulation and the way it is attached to the door. Sometimes a wooden frame is required, for example, for mineral wool with a waterproofing film. The slats are taken with a section of 20 x 40 mm, cellophane is used.

To soundproof the canvas, you will need tools:

- electric drill, screwdriver;

- a set of drills for wood or metal;

- a hacksaw for wood or a grinder with a circle on steel;

- knife, scissors, tape measure, square, hammer;

- stapler, Phillips screwdrivers.

For fastening the insulating material and cladding, hardware is prepared in the form of self-tapping screws with sweat, decorative finishing nails, and glue. In each case, the set of tools is different.

Procedure

Entrance doors should block more sounds than interior doors, so there are special rules for them. The outer surface is insulated, and the inner one is additionally sheathed with clapboard or lath, which also gives a sound-absorbing effect.

Not so strict requirements are imposed on internal doors. They protect the owner of the room from nearby household noise and ensure a comfortable stay. They are often insulated with spacers around the perimeter of the box, equipped with thresholds so that you can sleep without noise or watch TV.

Entrance door

The type of insulation depends on the sash material. A wooden door dampens more sounds than a steel one, so the entrance metal door is soundproofed from two sides.

Cladding procedure with laying of insulating material:

- remove accessories, a peephole, all protruding parts that interfere;

- degrease the surface with a solvent;

- foam plastic, polystyrene, isolon, foam rubber are glued, and mineral wool, felt, synthetic winterizer are nailed (wood) or screwed with self-tapping screws (metal).

A decorative layer, for example, leatherette, is nailed with finishing nails. A roller is formed from it along the perimeter of the canvas so that it extends beyond the perimeter, and when closed, closes the gap from the sound. Fittings are installed in place.

Interior canvas

Internal doors are soundproofed according to a similar principle with the use of a protective layer and decorative upholstery. If there is a room with increased noise, for example, for playing music, acoustic foam rubber is placed on the door. It must be glued on the side from which the sound originates, while the thickness should not interfere with the closure.

Isolation stages:

- sealing of mounting slots around the perimeter of the trap;

- degreasing the working area and gluing the filler from the noise side;

- stuffing of decorative cover.

There are special sound-absorbing panels up to 10 mm thick. They are glued onto mastic and covered with trim. A seal is mounted along the perimeter of the porch of the door leaf, rubber, foam rubber strips on an adhesive basis are used.

Sliding door

For such canvases, the sound insulation is too low due to the large gaps that are needed for the sash to move. There are doors that, when opened, hide inside the wall, others go outside along guide rails or awnings. The first option provides reliable protection against sounds, in the second case, the gap between the wall and the sash needs to be reduced.

Work order:

- change the skirting board in the work area to a thinner one;

- the upper part of the door is placed on special carriages;

- a brush-shaped seal is placed between the wall and the canvas.

- gaskets are glued to the casing or the panel covering the track.

There are ready-made sliding blocks made of sandwich panels with high noise insulation (about 50 dB). Structures are expensive and heavy.