The fireplace is an open stove where heat is generated directly in the combustion zone of the fuel. Brick fireplaces are built with a combined workflow and heat production area. An open firebox limits space heating due to heat conduction and convection, but increases the temperature around it due to wave heat transfer of a certain range.

Types of brick fireplaces

Modern devices mounted in an apartment or a room in a country house are not like similar structures that are installed in large mansions. You can afford to build a massive stone fireplace only if space permits.

Today, the decisive role is given to saving space, therefore there are 2 types of structures:

- built-in;

- attached.

There are decorative fireplaces that do not take up much space, projects include corner models. A distinction is made between a brick fireplace with an open, closed and semi-open heating chamber. Closed types are often combined with built-in options, when the chimney and wood-burning stove are in the wall of the room.

Built-in

Original designs are built with a firebox at the bottom of the wall or place it at a certain height from the base. The difficulty is that the depth of the hearth itself is about 60 cm, and the internal partitions are not so thick, so part of the firebox goes into the adjacent room.

The solution comes in the form of two options:

- decor for the back wall of the fireplace in the adjacent room;

- the device of a fireplace with a double-sided firebox.

The advantage of a structure with two hearths is that the fireplace has 2 glasses in different rooms or in different planes. This solution allows you to increase the functionality and quality of heating in cottages, apartments and country houses.

Corner structures are built in the process of building a house, since then it is problematic to build a fireplace into a corner. The supporting structures of supports and beams need to be rebuilt

Wall-mounted

The most common type, since it is not always possible to build not only a fireplace, but also a chimney into the wall. The cost of materials and work for the attached model is much lower, so there is a real cost savings. The room is heated more efficiently due to the side surfaces.

Such models are installed in living rooms where it is not possible to install a fireplace in the center of the room or in a suspended version. The traditional type has standard sizes, for which ready-made fireplace portals are suitable, for example, for an interior in the style of Gothic, classic, country.

A wall-mounted fireplace for a brick country house is easy to lay out in an already finished room. The main part is located not in the wall, but near it, so redevelopment is not required. The masonry of the fireplace portal can be of the same width over the entire height, taper towards the top, or triangular models can be made.

Fireplace device

Heating a room is caused by infrared heating, in which the surrounding objects receive energy, then transfer it into the air. Open fireplaces give little heat, and devices with a closed internal firebox heat a small house, a summer cottage.

In some buildings, an internal fan is installed to enhance convection currents and make heating even.

There are elements in the design:

- firebox - space for fire;

- chimney with a smoke chamber for collecting gases;

- fireplace base;

- portal.

The efficiency of an open fireplace is about 15%, and a closed firebox gives an efficiency of 60 - 70%. A wide chimney eliminates the suction of smoke into the room. The thrust is strong, the flow velocity in the pipe reaches 4-8 m / s.

Toplivnik

It is possible to build a fireplace with an open or enclosed area for fuel combustion. The firebox can be of various shapes, it is better to fold a rectangular or square structure. Dimensional parameters are calculated by heating engineers for typical projects or for individual construction.

The firebox is characterized by the following parameters:

- volume;

- power of the generated heat;

- fuel composition;

- the amount of ash generated.

Open fireboxes are part of the fireplace, they do not have a door. In closed ones, removable screens or a door for loading firewood are installed. Such elements are installed during the reconstruction of an old fireplace. When building a new one, ready-made furnaces made of steel and cast iron of a closed type are often mounted. They use firewood, coal, biofuels and gas, there are electrical models.

Chimney

It is an engineering system in the form of a vertical pipe with certain technical parameters for smoke extraction and traction. The combustion products are removed using the natural pressure difference in the lower and upper sections, or fans are used for forced movement.

Chimneys can be laid from materials:

- ceramic brick (walls 120 mm thick);

- heat-resistant concrete (walls - 65 mm);

- asbestos-cement pipes only for a temperature not exceeding + 30 ° С;

- steel pipes as sandwiches.

Modern channels are made of enameled collectors, vermiculite concrete, pipes made of glass and composite materials are installed. The height and section of the chimney is determined by the power of the furnace, taking into account safety. Technical requirements and standards are taken into account.

Base

The base is located between the firebox and the foundation. It is made in different shapes and designs, depending on the level of the combustion chamber. For better heating of the room, a low location of the hearth is used so that the heat source is almost level with the floor. Such a profitable option is not always possible.

Problems arise if a fireplace is built in a finished house, because you need to cut out a section of a reinforced concrete slab or take part of the basement space for the foundation of the structure. The technology requires that there is a gap under the base plate for ash collection and air flow with access for maintenance.

The base is chosen according to the thickness of the fireplace walls; it is often made in 4-5 bricks in height. The depth of the base depends on the dimensions of the firebox.

Portal

This is a decorated front with a firebox frame. Portals are made with different materials, for example, facing brick, natural stone. Decorations are widespread in the form of carving, stylistic elements that focus on the interior of the room.

Requirements for the construction of portals:

- Safety in terms of fires, therefore non-combustible materials are used.

- No risk to human health - casing with low heat conduction is used, so as not to get burned when touched. Also, the cladding should not emit toxic and harmful components when heated.

In the classics with monumental architecture, Gothic, fireplaces are decorated in spacious halls. For small ones, they use ethnic country. Medium rooms are equipped with high-tech, minimalism, romanticism hearths.

The shape and size of a brick fireplace

The shape of the fireplace depends on the preferences of the owner. There are no universal proportions of the structure, the parameters depend on the quadrature of the room, the recommendations of the engineers and the standard size of the elements of the masonry material.

To find the dimensions of the furnace, the area of the room is determined, the value is divided by 100. This is how the bottom of the furnace is squared. For example, a 30 m² room would require a 0.3 m² camera base. The depth is always made 1.5–2 times less than the width. For a 0.3 m² firebox, where the width is measured by three bricks (75 cm), the depth is 37.5 cm.

The height of the masonry walls of the combustion chamber is equal to the width multiplied by 1.5. For a width of 3 bricks, it is taken at the level of 15 masonry rows.

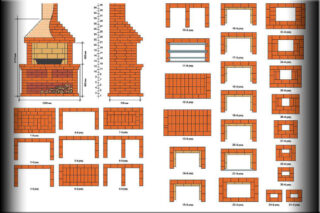

Drawings and orders

Homeowners are trying to build a fireplace with their own hands, they make drawings on their own or take standard designs.

The project includes:

- sketches;

- sizes of functional areas;

- localization;

- front, side views;

- fireplace cuts.

For construction, it is important to use orders. In each row, a certain layout of bricks is given, the effective operation of the structure depends on following the scheme. Full bricks, halves and small quarters are shown, embedded parts, width and height of joints are taken into account.

Brick and mortar

For masonry, they take ceramic bricks, which have low permeability to moisture. The material resists high temperatures well, does not degrade from the chemical ingredients of the smoke. White silicate bricks are not used due to their strong water absorption and lower strength.

Fireclay brick is used directly for the firebox, which resists heat more. Ceramics and chamotte have different coefficients of expansion when heated, so they are not tied together in the fireplace so that there are no cracks. The brick is cut by hand, or sawn with a grinder. In the first case, when cutting down a half, the second part of the brick will always be damaged.

They prepare a sandy-clay solution on their own, take clay of a fatty grade without the inclusion of another substance. Sand is used, which is sieved through a sieve with a mesh of 0.3 - 1.5 mm. Clay is kept in the open air, it is better if it will be in winter.

Before mixing the solution, the clay is soaked in water for 4-6 days, then the resulting dough is filtered, stones are selected. The proportion of clay to sand is 1: 1 - 1: 3, this is determined by the fat content of the former. An excess of clay will lead to fluidity and cracking, a deficiency will make the solution dry and immobile.

Sell ready-made dry mixes for laying stoves and fireplaces. They are packaged in bags, you need to add water to work.

Phased construction of a brick fireplace

Fire safety requirements are taken into account when choosing the location of the hearth. This is especially important in wooden houses. For this option, a separate hinged chimney is chosen, and when passing through the roof, good insulation is made. The pipe should not touch the structural elements of the roof, for example, rafters, beams, battens.

It is undesirable to put the heat source against walls where there are windows or an entrance door. The draft in the chimney of the fireplace is strong enough, so a draft will appear. But the flow of fresh air also needs to be organized so that the combustion is more intense. A rigid and solid base is required, since a brick fireplace has a significant weight.

Laying the foundation

The support is built so that there is no connection with the supporting base of the building. If the fireplace is arranged next to a loaded wall, a layer of sand with a thickness of at least 6 cm is made between the two foundations. The base is poured to such a height that the first bricks of the masonry become flush with the finishing of the floor.

A cushion of sand and gravel is made under the concrete, a layer of waterproofing is placed so that the edges cover the walls of the formwork. Concrete is prepared in a ratio of 1: 3: 5 (cement, sand, crushed stone, respectively). Reinforcement mesh is installed in the mass. The dimensions of the base make the bottom of the hearth more than 100 mm from each side. The formwork is removed at 8-10 days, and the laying begins after two weeks.

Brickwork masonry

The walls are driven out according to the ordering scheme.

DIY step-by-step instructions for a brick corner fireplace:

- make the laying of internal partitions from chamotte bricks;

- external walls are made of ceramic elements;

- on the corner joint, diagonal cuts are provided;

- a metal strip is placed in the twelfth row;

- in the area of the back wall, a brick is placed with a poke to form a vault from 13 to 16 rows;

- the narrowing of the smoke channel starts from the 15th row, and at 16 the damper is again expanded and mounted to clean the chimney.

Before starting work, the wall behind the hearth is insulated from heat with a steel sheet or thick foil, and wood partitions are impregnated with fire retardants. A metal covering is placed in front of the firebox door so that the floor does not catch fire from the fallen coals and sparks.

Chimney construction

The channel is made with a rectangular or square cross-section measuring 14 x 20 or 14 x 14 cm. The masonry is made with butt or spoon rows. Inside, it is not permissible to leave an influx of mortar, you need to fill the seams, and iron it until a smooth plane is obtained. The outer part of the chimney is plastered, but the inner part is left without such finishing.

Sometimes, inside the masonry, a mounted pipe is placed, the lower edge of which is mounted directly on the stove. Docking is accompanied by brick binding for reinforcement. The top of the chimney is brought out above the ridge of the roof by 0.5-1.0 m, so that there is a strong draft.

Mantel

Finished masonry is finished with tiles, marble, facing bricks, natural stones, tiles. Various shelves are made above the firebox, there is an option for placing a TV, a clock. First, the bottom of the fireplace is sheathed, tile adhesive is used.

Forged lattices or decorative metal elements, sculptures are used in the design. Wooden trim parts are insulated from heat, covered with protective compounds. The cladding must withstand high temperatures without deformation and peeling, the material must be easy to maintain, clean, and durable.