The installation of aluminum windows is a popular activity in private and commercial construction. This is justified by a number of positive characteristics inherent in structures of this type. One of the selection criteria is the possibility of glazing the veranda with an aluminum profile with your own hands. To perform such a task efficiently, you should familiarize yourself with the varieties of existing structures, the rules and features of their selection and assembly.

Varieties of aluminum windows

Modern technologies have significantly expanded the possibilities of engineers and designers with regard to the form and content of aluminum window systems.

Products may have such a device:

- Folding. They are a sash that rotates on the lower hinges and moves away from the upper crossbar of the box at a certain distance. It is used for lighting and ventilation of confined spaces.

- Swivel. Classic model with one sheet. Fastening is carried out on the vertical posts of the jamb, swinging is carried out to the right or left.

- Swing-out. The frame can be rotated sideways or upward; most models have a micro-ventilation function. The most popular option in residential, utility, commercial and office buildings.

- Deaf. The frame is missing. The glass unit is attached directly to the box. In residential construction, they are installed in rooms with a large number of openings, attics, and other rooms where effective ventilation is installed.

- Multi-leaf. They are used to equip wide window openings with sashes with the same or different parameters. Each frame has its own opening mechanism.

- Sliding. They work on the "coupe" technology. Most often they are used for equipping narrow rooms, such as balconies, loggias, small kitchens.

According to the degree of thermal insulation, systems are divided into cold and warm. The former are used in rooms that are not heated. The second - inside houses, dachas and apartments.

Having experience in working with metal, it is possible to make frames not only rectangular, but also of a more complex shape.

Features of sliding systems

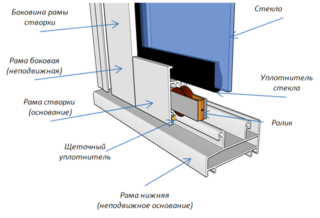

Externally, sliding systems practically do not differ from folding, hinged and deaf models. They have frames, double-glazed windows and handles. They are made from similar profiles. The only difference is the opening mechanism. Sliding structures move to the side along the rollers that move along the upper and lower guides.

Fasteners and runners, unlike hinges, experience the greatest dynamic load in the system, are exposed to moisture, temperature extremes and ultraviolet radiation. The strongest and most durable materials are used for their manufacture. To protect against corrosion, a polymer coating is applied to the metal.

Advantages and disadvantages

Aluminum profile sliding windows have a number of advantages that have not gone unnoticed by private developers and city apartment owners.

- Ease. Aluminum has a specific gravity three times less than that of iron. Frames made of this metal are lightweight, so there is no need to make massive guides and brackets supporting them.

- Excellent heat and sound insulation properties. A lightweight insulation with high performance characteristics is installed in the profile.

- Presentable look. The frames have a small width, which increases the degree of illumination of the premises.

- Saving usable space. When folded down, the sash takes up a minimum of space. This allows you to install cabinet furniture and makes it comfortable to move around the opening.

- Compatibility with blind flaps. One structure can consist of several movable frames.

- Resistant to corrosion, mold and mildew, active chemical reagents.

- No need for additional finishing and decor. Scuffs and scratches can be easily removed by yourself using commercially available products.

- Long service life with minimal and easy maintenance.

- Wide range of applications. It is possible to install aluminum windows in buildings of any purpose. The choice is made only in favor of one or another type of thermal insulation.

Non-ferrous metal products have weaknesses. First of all, the cost. In the absence of a high-quality coating, the surface fades and becomes porous under the influence of ultraviolet radiation. The strength of aluminum is lower than that of iron and this implies certain limitations in design and construction.

DIY installation technology

To carry out the installation of aluminum windows, it is necessary to prepare certain tools and materials:

- puncher, screwdriver;

- level, tape measure;

- hammer, nail puller;

- putty knife;

- ax;

- stationery knife;

- hacksaw for wood;

- hex keys;

- pliers;

- anchor bolts 10 mm;

- polyurethane foam;

- sand, cement.

To install an aluminum profile window, you need to do the following:

- Dismantle the old structure. If the opening is badly damaged, restore it and level it with cement mortar. If the frames removed are wooden, make wedges out of them.

- Disassemble the kit. Carefully remove the shutters and remove the glass from them. Drill 4 holes in the frame on the sides and 2 each at the top and bottom.

- Place the frame in the opening. Align the product vertically and horizontally using a level and wedges. Ensure that there is the same clearance on all sides of the box.

- Drill holes in the wall through the holes made in advance. Insert and tighten the anchor bolts without deforming the frame.

- Place spacers in the box and seal the seams with polyurethane foam. It is better to remove wooden wedges, as they expand from getting wet and can bend the frame of the window.

- Hang the sash, return the double-glazed windows to their places. Check the quality of opening and closing. If necessary, adjust the mechanisms.

It remains to install the window sill, slopes and ebb.

Features of the installation of sliding systems

The assembly of aluminum sliding windows is somewhat different from the installation procedure for pivot and blind structures. First of all, this is the absence of a rigid connection between the frame and the sash.

- Remove the old structure from the opening, repair, align and strengthen the walls.

- Remove the glass unit and the sash from the box, put them in a safe place. Drill the required number of holes in the jamb.

- Insert the frame into the opening, align, secure with wedges. Then drill holes in the wall, fasten the profile with anchor bolts.

- Fill the gaps on both sides with polyurethane foam. Pre-moisten them with water. Wait until it hardens completely, cut off the excess.

- Measure and cut out the guides, the length of which will ensure the full rollback of the sash. Finish the edges of the gutters.

- Attach the rails to the top and bottom of the frame with a screw pitch of at least 30 cm.

- Attach the rollers to the sash according to the instructions. This is usually done 5 cm from the edges.Fasten the seal around the sash.

- Place the window in the guides. First, insert the rollers into the upper part, and then lower them into the lower part.

- Insert the glass unit, fix it with glazing beads.

In conclusion, the product is adjusted using adjusting bolts.

Caring for aluminum windows will not cause serious trouble. Periodically, they must be cleaned of dirt and dust, avoiding the use of abrasive agents. Swivel joints and adjustment mechanisms should be lubricated every six months. Replace the seals and glass units as they wear out.