The usual swing garage doors are gradually becoming a thing of the past, giving way to more perfect, convenient and ergonomic systems. Their cost is slightly higher, but you can save money by doing the installation yourself. Installation of Alutech gates is a laborious, responsible, but quite feasible process. To achieve a high-quality result, you need to familiarize yourself with the features of the product, carry out calculations, choose the right equipment and install it in accordance with the manufacturer's instructions.

Advantages of Alutech doors

Structures are purchased in standard sizes or made to order.

Users note the following advantages of ALUTECH sectional doors:

- High strength, providing reliable protection against burglary, accidental and deliberate mechanical stress.

- Resistant to corrosion. All parts are made of stainless steel or coated with zinc, varnish, polymer spraying.

- Presentable appearance. The products look expensive, flashy and prestigious.

- Long service life. The products are designed for 25,000 cycles, which with daily use is 15-20 years.

- A wide range of design options. With the standard 10 colors, there are over 200 shades. In addition, models with windows and wickets can be purchased.

- Excellent thermal conductivity. With a leaf thickness of 45 mm, it corresponds to a brick wall of 60 cm.

- Safety. The gate is securely held in sliding guides, protection against pinching of fingers is provided.

- Tightness. The sections are equipped with petals and seals to prevent moisture, dust and drafts from entering the garage.

- Silence. The operation of double rollers with rolling bearings is virtually silent.

- Possibility of self-assembly of Alutech doors. Detailed instructions make this event as simple as possible.

An important factor in favor of choosing a gate is its cost. It is quite affordable for people with an average income level.

Varieties of gates

The developers of the Belarusian company have designed and created a reliable, functional and at the same time accessible entrance system that meets almost all the requirements and wishes of users.

Depending on the quality of the materials used, the complexity of execution and configuration, the following models are produced:

- Prestige;

- Classic;

- Trend.

A choice of designs is presented according to the lifting height:

- standard;

- high;

- low.

Gate control is carried out manually or with an electric drive, with or without automatic equipment. The balancing mechanism of the canvases is selected for specific conditions. Selectable tension spring system or torsion block.

Preparatory work

A person who has basic skills in working with household tools can assemble Alutech sectional garage doors. The main problem is not the assembly procedure, but the foundation. There are two criteria here - the correctness of geometry and density, since almost all garages today are built from aerated concrete.

Do-it-yourself step-by-step process for preparing for installation:

- Measure vertically, horizontally and diagonally. Indicators along the corresponding lines should not differ by more than 5 mm.

- If the walls are thick and made of dense material, level them with cement mortar using beacons and a rule.

- If necessary, if the supporting structures are thin, uneven and fragile, weld the frame structure from the outer and inner contours. Secure it with extended length anchor bolts.

- Fill gaps with cement mortar or zero expansion foam.

Garage doors are 40-45 mm thick, so they do not freeze. Based on this, it is necessary to get rid of the lateral gaps. The structure itself will be adapted to the existing opening if it is not made to the standard.

For the manufacture of the frame, you must use a profile pipe with a wall thickness of at least 6 mm. The apparent lightness of the structure, the feeling arises from the ease of its movement, which is provided by the balancing mechanisms.

How to fix guides

Installation instructions for Alutech doors give a detailed description of the work, indicating the smallest details, nuances and even the category of tools. The first step is to install the guides.

The procedure is carried out in the following sequence:

- Checking the completeness of the product, its compliance with the dimensions of the opening.

- Marking. Drilling holes for anchor bolts.

- Fastening the guides to the bases. First, the vertical profiles are attached, then the ceiling profiles. This will require the help of several people to lift, fix and screw the structures.

At the end of the work, the compliance of the dimensions with the diagram attached to the kit is checked. Deviations within 2-3 mm are allowed. If more, you need to remove profiles, install gaskets and take other measures to eliminate defects.

How to install panels

The web is assembled from sections, hinges, rollers and fasteners. The advantage of Alutech gates is that the rollers are initially aligned with the hinges.

Installation sequence:

- Installation of the first section on the floor of the room. Bringing out the horizontal line of its top edge.

- Attaching the roller block to the panel. The connection of the wheels with the guide from the top and then from the bottom. Fixing parts with bolts.

- Docking of the second section. It is placed on top of the first and connected to it with loops. If the canvas is wide, two or more loops are added. This will strengthen the structure and prevent it from sagging.

- The rest of the panels are connected in a similar way. There are usually four of them.

- Checking for miscalculations. If they remain, then they can later be eliminated by installing the seal on the canvas or supporting frame.

The Alutech gate system is so simple and well thought-out at the same time that the assembly process takes no more than an hour.

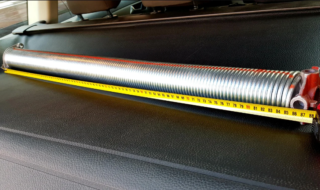

Installation of springs

In modern Alutech models, a double spring is used, which replaces the torsion shaft. It has a complex structure and its cost is several times higher than that of other gate manufacturers, and its repair and straightening is impossible. Therefore, this stage must be approached with the utmost responsibility and accuracy.

- Screwing the handle to the holes specially made for it.

- Installation of spring valves on the second and third sections.

- Fastening the cable with one end to the roller loops, and the other to the upper protrusion on the guide.

- Establishing a cable to the spring, adjusting it, fixing the desired position with bolts.

Finally, a web retainer is installed. The gate rises, the place on the upper rail is marked where they end and the retainer is screwed on there.