Garage doors can be hinged, sliding or lifting. Of the latter, sectional models assembled from sandwich panels are especially popular. They are very practical, comfortable and do not take up space when opened. However, installing this kind of garage door is difficult and requires skill.

What you need to know about sectional doors

This model got its name because of its design. In the usual case, the sash is a solid rigid sheet. Sectional structures are assembled from elements. The fastening between them is solid, but not rigid. Such a canvas is able to bend and even roll up into a roll - for example, roller shutter models.

Most often, the sections are a variant of the sandwich panel. This is a slab made of polyurethane foam - a heat insulator with a high level of heat saving, and protected on both sides by galvanized steel sheets. The composite is lightweight and durable, but also warm. They produce panels with finishing not only from steel, but also from chipboard material or lining.

Sandwich panels are most often used in the design of lifting gates, since this is where all the advantages of the material manifest themselves most strongly. When opening, such a model does not swing open, but rises along the guides, changing the angle of inclination, and stops in a horizontal position. The lifting height depends on the purpose of the garage - for cars, trucks, buses. In this case, the door leaf does not take up space in the opening or near the wall.

Installation of sectional overhead doors in the garage will allow:

- save space;

- insulate the garage, as sandwich panels will prevent heat loss;

- stabilize the temperature and humidity conditions inside the room.

The lifting gates are allowed to be opened manually. But more often they are equipped with an electric drive and are controlled from the remote control.

Varieties of sectional door designs

Sectional models are distinguished by purpose:

- Garages are small in size, as they are designed for private garages or parking spaces in shopping centers. Ceiling mount. The sections are made of different types of sandwich panels, as they provide thermal insulation for the box. The models are very attractive. Often they imitate wood paneling, they can have an unusual embossed texture. They are controlled manually or automatically.

- Industrial - designed for use in harsh conditions. They are not always insulated, but they provide the maximum level of protection against chemically aggressive substances, provide high tightness when closing and most often act as an element of sound insulation. The sizes are various. Industrial gates are necessarily equipped with an electric drive, as well as a reinforced chain system, which allows you to open a heavy sash in case of a power outage.

- Models with a wicket are an expensive variety. The wicket is installed directly in the leaf of the sash. It consists of sections and bends, therefore it has a complex structure. However, for a private house or small business, this option is the most convenient.

Sectional doors are produced by many Russian and foreign companies.

Requirements for the opening and its preparation

Installation of sectional overhead doors is a complex job that requires high precision.The opening mechanism assumes free displacement of the sash along an arc, during which the sections change the angle of inclination to each other. Difficulties at any stage lead to the fact that the flaps stop opening.

The most important part of preparation is size.

It is necessary to accurately determine the dimensions of the opening itself and the garage.

- The height of the opening is determined. This is not an absolute value, but the height required for the vehicle to pass. According to the rules, the distance between the roof of the car and the ceiling, in this case the sash from above, must be at least 30 cm.

- The lintel is measured.

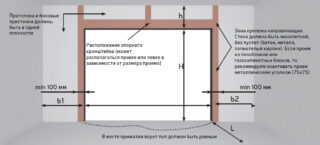

- Determine the width of the opening. When installing garage overhead doors, 2 cm are left on both sides of the working opening for installation. The required value is the sum of the width and 4 cm.

- To service and install the frame, some space is required - 8 cm on each side.

- The depth of the garage must exceed the height of the door leaf in order for the sash to fit horizontally in the room.

The measurement results are transferred to the manufacturer's workshop, and the dimensions of the system are calculated from them.

Wall material - gas silicate block, foam concrete, aerated concrete, corrugated board, timber - does not affect the dimensions of sectional models. But it matters for the design and installation of the frame.

Preparation for installation of sectional doors

Do-it-yourself installation of sectional doors begins with preparation. The step-by-step instructions include the following steps.

- The walls and ceiling are trimmed, if this has not been done. Most often they are plastered, since this material allows you to level the surfaces.

- Check the plane of the walls relative to each other. The frame can be mounted on curved surfaces, but this requires special fasteners and makes the entire structure unreliable.

- The partition and the lintel are closed up with a metal corner.

If the overhead gates are installed in the finished garage, replacing the swing doors, other measures are also included in the preparatory work. You need to move the ceiling lights, take care of the electrical wiring, remove the heat gun if this is how the garage is heated.

Tools and materials

To assemble a sectional garage door, you will need:

- electric drill or screwdriver;

- hammer drill with victorious drills;

- fasteners - usually included;

- level, tape measure, plumb line.

If you do not have a lot of experience in the installation of complex building structures, it is better to entrust the assembly to professionals.

Installation steps

Collecting panels between each other is a very difficult and painstaking job. Therefore, ready-made models are more often purchased. Installation of a garage door is carried out as follows.

- Mark the wall under the frame. Places for suspensions are determined on the ceiling.

- Install vertical elements and check with a plumb line. Fastened with mounting screws.

- Horizontal beams are mounted. In relation to the verticals, they are placed strictly at 90 degrees. They are fixed horizontally with hangers - to the ceiling or beams.

- Collect panels if the canvas is not purchased ready-made.

- They ensure the tightness of the closing - a rubber seal is attached to the lower edge of the sash, and a rubber seal is attached to the sides and top.

- Insert the web into the guides and check the progress. It is necessary to ensure that the sections are tightly pressed against the upper sash.

- Install controls: handles, locks. Then balance springs are installed.

- Limiters are mounted. If the doors are automatic, connect the electric drive.

The metal box may be too light for such a model. The walls and lintel are reinforced with a pipe frame before installation.

Checking the operation of the gate

After the installation of the doors, their functionality will be checked:

- The canvas is raised and lowered several times in automatic mode and in manual mode. It should move smoothly, without effort or jerking.

- When lifting and lowering, there should be no gaps between the sections. This indicates a loose joint between the panels.

- Press on the bottom and top panels of the web. No gaps should appear between the sash and the opening.

- They do not raise the canvas completely and stop it - the gate should be milled in this position, and not moved by the force of inertia.

If the work was carried out by a team, it is necessary to make sure that the panels are intact, that there are no scratches, chips and dents.