Entrance doors to any type of premises are made of materials such as plastic, wood or alloy steel. Plastic and wooden doors are most often installed in protected areas (hotels, office buildings, etc.), steel doors are purchased by the owners of private houses, summer cottages. The installation of metal doors in the apartments of urban high-rise buildings has become popular.

Advantages and disadvantages

Steel doors are able to prevent unauthorized entry into a home and thereby ensure the safety of material values and the safety of people inside.

Metal entrance doors are made of two steel sheets, between which there is a thick layer of heat and sound insulation, which allows you to reliably protect the room from extraneous noise and cold. Also inherent in metal doors:

- strength;

- durability;

- operational reliability;

- versatility - they are mounted in the doorways of houses built of concrete, brick, wood.

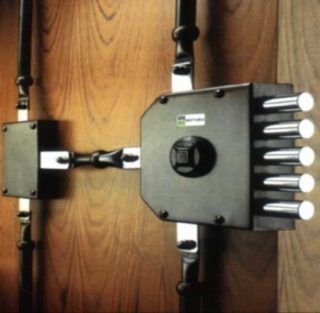

To exclude the possibility of burglary, the doors can be equipped with:

- high stability locks;

- multilevel locking mechanisms;

- adjustable hinges;

- eyes with an extended viewing angle and other accessories.

The door installed in accordance with all the rules will not require repair for a long time. Its surfaces can be decorated in any way available to the owner - veneer, natural wood, stone inlay or elements of artistic forging.

The main disadvantage of metal doors is their heavy weight. A quality alloy steel entrance door can weigh from 60 to 120 kg. This significantly complicates transportation and installation.

The remaining disadvantages relate to cheap thin metal products:

- A door made of thin metal is easy to pierce even with a can opener. The thin and soft material is indicated by the presence of stamped relief elements, which will immediately attract the attention of intruders. Special armored pads protecting the lock will not help - they can be easily cut out.

- A box made of thin metal, which is filled with polyurethane foam for insulation, can deform.

- Poorly made doors rarely open and close smoothly. To eliminate this defect, you will need to install porches.

- In the presence of metal parts common to the inner and outer parts of the door (cold bridges), the leaf and the box will freeze in winter, and the box will be cold even indoors, and the outer part of the door leaf can be covered with frost or ice.

Thin metal entrance doors can be used to equip the vestibule.

Mounting methods

Entrance metal doors are fixed in the wall opening in two ways:

- using special mounting plates;

- in-wall method.

Door frames with 4 metal plates welded on the sides are used to install entrance doors to apartments in multi-storey buildings, where the thickness of the walls of the doorways is less than 20 cm.

In-wall boxes are used when the wall thickness exceeds 20 cm, for example, in private houses. In them, the mounting holes are located directly in the walls of the box.

Do-it-yourself installation of metal entrance doors

For installation work, you will need the following tools and materials:

- Bulgarian;

- scrap;

- rack level;

- puncher;

- a hammer;

- roulette;

- anchor bolts;

- polyurethane foam;

- wooden wedges.

A hacksaw and a sledgehammer will also do the trick.

Before installing a metal door, you need to prepare a wall opening:

- Dismantle the old door leaf and hinges.

- Using a grinder or a hacksaw, an old door frame is cut into the wood.

- Using a crowbar, break down the door frame.

- Grinder and perforator remove the remnants of mortar and plaster.

At the end of the work, they remove the debris and inspect the threshold - it should be flush with the floor. The old timber must be removed.

The next step is adjusting the wall opening to the dimensions of the new door frame. If the opening is already a box, it is expanded with a punch and grinder. If wider, they narrow it, applying a layer of cement mortar in the right places.

Installing a steel door in a wall opening will not be difficult if two people are involved in the process. The work must be carried out in a strict sequence:

- The box is put in its place. To prevent it from falling, open the door 90 ° and substitute a support.

- With the help of a rack level, the door frame is fixed in such a way that all its planes take a clear position relative to the vertical. The procedure begins with the part of the door on which the hinges are located. If necessary, wooden wedges and blocks are substituted under the lower opposite edge of the box. If the door is assembled with high quality, all other planes should be positioned correctly.

- Proceed to fasten the door frame. To do this, first drill a hole in the wall through the upper fixing hole on the side of the hinges and insert the anchor into it. Then repeat this procedure with all mounting holes located on this side of the box.

- They go to the opposite side of the door frame and repeat the process in the same way.

- Clamp the anchors installed from the side of the hinges, while clearly maintaining the vertical. The process is controlled by a level that will clearly show which anchor needs to be clamped and which one should be released. Having finished with one side of the door frame, they move to the other, repeating the process of tightening the anchors.

As a result of the work performed, the door block will hang in the space of the wall opening and sometimes it can even swing a little. This is not a defect, since it will finally be fixed during sealing.

Before sealing the door unit, it is necessary to check its functionality. To do this, close the door and watch how the lock clicks. If at the same time the bolts of the lock cling to the counter holes, the door block requires additional level adjustment. If everything is fine, proceed to the sealing process.

The door block is sealed with polyurethane foam, which is blown into the slots between the frame and the wall opening using a special pistol. The process starts from the sides, and then goes up. The foam is not blown out under the threshold - there the space is filled with mortar. This is due to the fact that the foam from constant loads collapses over time.

At the end of the work, do not use the door for at least 6 hours. This will allow you to securely fix it in the wall opening.

Installation of an iron door in a wooden house

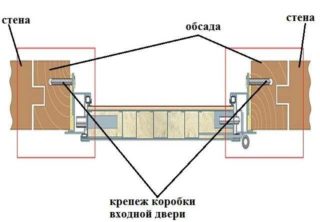

The algorithm for installing an iron door in a wooden house practically does not differ from the described process.The only difference is that the door block is installed in the casing, which will prevent the displacement of the logs, and in the future will take on most of the load.

The casing box is a simple design:

- side racks (2 pcs.);

- transverse top rail;

- threshold.

A gap of 5 to 7 cm is left between the upper edge of the doorway and the transverse rail, which is subsequently filled with insulation and closed with a casing. All parts of the casing are fastened with self-tapping screws with countersunk heads and a length that is 2 times the thickness of all rails. When choosing the dimensions of the casing, the dimensions of the door block must be taken into account. The gaps between the boxes should not be more than 4-6 mm on both sides. This design reliably protects the metal door block from the shrinkage of a wooden house.

- chisel;

- hacksaw for wood:

- drill;

- screwdriver.

The metal door frame is installed in the casing without a door leaf, which is hung after the completion of the installation work.

The design of a door block intended for installation in a wooden house must have increased rigidity. Therefore, the recommended thickness of the metal sheet from which the door is made cannot be less than 2 mm.

Errors when buying and installing metal door blocks

When purchasing entrance metal doors, you need to pay attention to its technical characteristics, which must necessarily correspond to the room. These parameters include:

- dimensions;

- weight;

- design.

The door leaf must be assembled from two solid steel sheets with a thickness of at least 2 mm each. A layer of sound and heat insulation is laid between these sheets. It is necessary that anti-removable pins are welded to the door leaf, and it itself has a total thickness of at least 40 mm. The hinges must be steel.

The entrance metal door must be equipped with an internal bolt and two different types of safe locks. In addition, the door lock must have at least two burglar-proof anchor pins.

If the measurements of the wall opening and / or its subsequent adjustment to the existing door block are made without taking into account the gaps that will be needed during installation and adjustment operations, distortions cannot be avoided. This, in turn, will lead to the destruction of the entire structure. Overestimated gaps will lead to a deterioration in security, since such a door block can be easily knocked out by intruders.

The distortions of the door block are possible in the following cases:

- The installation of the door block was carried out without using a building level.

- Anchor holes are drilled too close to the edge of the wall opening, causing the wall to collapse over time.

- Anchor holes are not drilled deep enough.

The installation of the iron door should be carried out using all the fastening points provided for by the design and specified in the instructions. Otherwise, reliable operation is not guaranteed.