The building structures of the bath are regularly exposed to aggressive moisture and high temperatures. Bath insulation significantly reduces or completely prevents unpleasant consequences, and also improves the quality of use of the building. For each room, different protection options are chosen, which you need to know about before starting the interior decoration.

Functions of heat-insulating and moisture-proof materials

The normal microclimate conditions in the steam room of a Russian bath are considered to be temperatures from 40 to 70 ° C with a humidity of about 80%. In the sauna, the air is heated to 120 °.

There are two types of insulation: internal and external. Which way to go when doing work independently depends on the tasks to be solved and the skills of the owner.

Internal thermal insulation for the bath helps:

- protect the building materials of walls, ceilings and floors from moisture, leading to the rapid onset of mold or mildew;

- to speed up the process of heating the steam room and utility rooms in order to save time and energy resources;

- keep the temperature acceptable for the procedures longer without resorting to additional heating of the furnace;

- save money on building materials - with high-quality thermal insulation, the walls of the bath can be made thinner, which also reduces the cost of the foundation.

Depending on the type of building, various insulation materials are chosen, taking into account the properties of the enclosing structures. Be sure to pay attention to the safety of insulation materials for the bath.

Types and characteristics of heaters

Manufacturers offer a large assortment of heaters, various in characteristics and materials used in the production.

Styrofoam

Under a general term, manufacturers combine the two types of material. Foamed polystyrene (polystyrene in everyday life) and extruded polystyrene (penoplex) have very low thermal conductivity - 5 cm of material retains heat in the same way as masonry in one and a half bricks. The sheets practically do not absorb moisture, therefore, they are suitable for insulating the bath inside on their own.

Do not use styrofoam in steam rooms and shower rooms. Condensation accumulates on the surface of the heat insulator and leads to rot, mold and mildew.

For thermal insulation of rest rooms, hallways, changing rooms, it is better to choose foam plastic, since it is 1.5 times cheaper than foam plastic with similar characteristics, so it makes no sense to overpay.

Mineral wool

Different types of heaters are called minvata due to the fact that natural substances are used in production, and the content of organic matter in products, as a rule, does not exceed 3-5%.

Mineral wool includes:

- glass wool, consisting of thin glass fibers;

- slag wool from metallurgical production waste;

- basalt insulation made of natural stone, which is melted during the production process and made the finest fibers woven into mats.

Only basalt insulation is suitable for insulating a wooden bath from the inside, being safe for humans at any temperature and humidity.

Material:

- moisture resistant;

- does not burn;

- does not rot;

- easy to install.

When installing, it is important to place a waterproofing layer between the interior finish and the mineral wool to prevent moisture (vapors) from entering the material.

The use for floors in damp rooms is limited, since in this case it is very difficult to protect the mineral wool from the flowing water.

Fibrolite

The heat insulator is made by pressing sawdust, and cement milk is used as a binder.

Fibrolite is safe, non-flammable, has high thermal insulation properties, is not subject to decay.

The material is used in any room to insulate walls, ceilings, floors.

Fibrolite is used for laying under the lining or finished with plaster.

Foam glass

Foam glass meets all the requirements for insulation. Produced by sintering silicon oxides, it is a porous material. Available in slabs of various sizes and thicknesses.

It is attached to the walls with glue or self-tapping screws through the drilled holes.

Withstands any temperature that may be in the bath. In addition to insulation, the material can be used to protect walls from the heat of the stove.

The disadvantage is the high price.

Ecowool

Natural material is used to insulate dry rooms. In a steam room or a washing room, it quickly becomes saturated with moisture, cakes, and loses its positive properties.

Available in rolls or sprayed using special equipment. The second option does not allow you to insulate the bath from the inside on your own.

Bung

The service life of the cork agglomerate reaches 50 years. The material does not crumble, does not lose its properties when exposed to high temperatures and moisture. Pressed sheets are used in any room of the bath, including the steam room and sauna.

Termolene

The material is completely natural and safe. Easily bends and wrinkles, therefore it is suitable for insulating uneven walls with grooves and protrusions.

Suitable for any premises.

Teploizol

Teploizol is a foamed polyethylene resistant to temperature and moisture. To insulate the steam room from the inside, choose a foil type of product.

The metallized layer completely reflects heat, preventing it from leaving the room. The foil prevents moisture from penetrating the walls, which reduces the risk of mold and mildew.

Penoizol is not gnawed by mice, insects do not settle in the material.

Bath insulation process

Depending on the material from which the enclosing structures are made (walls, floor, ceiling), different materials are chosen and various technologies are used.

Floor insulation

Bath floors are either concrete or wood.

The concrete floor in a separately located bath is made in the form of a pie of several layers.

Algorithm for thermal insulation of the sauna floor:

- Thoroughly clean the soil from construction debris, plant residues. The roots of perennial and woody plants are uprooted.

- Fill in a pillow of 10-15 cm of sand mixed with rubble, fill it with water and ram it.

- Lay a layer of waterproofing so that at a high level of groundwater, moisture does not leak into the room.

- A 15-centimeter layer of expanded clay is poured and leveled, which serves as a heater.

- Lay out a reinforcing mesh with a 10x10 cm cell.

- The finishing floor is poured using a cement-sand mixture.

- Laying ceramic tiles or porcelain stoneware.

A wooden floor on the ground is made according to a different scheme:

- Clean the surface.

- A 10 cm sand cushion is made.

- Pour the rough screed.

- Install wooden logs with a section of 5x10 cm or more.

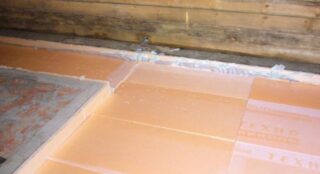

- They fill up expanded clay or insulate the floor with sheet materials - foam plastic, basalt sheets.

- The waterproofing layer is nailed using a counter-lattice bar.

- The finished floor is nailed onto the counter-lattice.

Another option is to arrange the floor on hanging logs:

- They attach the logs to the walls or lean on red brick or concrete posts.

- From the bottom to the logs, a rough floor is nailed from unplanned boards. To reduce the cost, it is allowed to use unedged timber.

- A layer of waterproofing is attached between the lags.

- Insulation is placed - polystyrene, mineral wool, penoizol, expanded clay.

- Next, the waterproofing, counter-lattice, finishing floor are nailed.

In shower rooms, they must carry out reliable waterproofing and arrange a floor with a slope for water to drain.

Wall insulation

Depending on the material of the walls, different methods of heat retention are chosen.

Log baths are appreciated not only for environmental friendliness, but also for their appearance. Therefore, they try not to add any additional elements.

The gaps between the logs are sealed with jute and flax. The operation is repeated as it shrinks, as well as in the spring and autumn periods.

A modern way to eliminate the gaps between rows of logs or beams is to use an inter-row insulation at the laying stage. The material is produced in the form of ribbons, but made from jute. The thickness of the strip is from 4 to 15 mm, which allows you to select the desired modification depending on the quality of processing of the building material.

Insulation of walls made of bricks or expanded clay concrete blocks is carried out from the inside.

Operating procedure:

- They clean the walls from the influx of masonry mortar, dirt and dust.

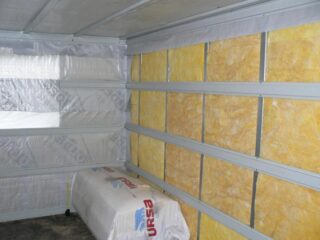

- The crate is nailed from wooden bars or galvanized steel profiles. Foam blocks are pre-plastered, as they actively absorb moisture.

- Sheets of thermal insulation are laid out and strengthened from various types of foam plastic, basalt wool, penoizol and other materials acceptable for a particular type of premises.

- A layer of waterproofing is nailed down. Foil-clad penoizol is considered an excellent option.

- A counter-lattice is attached to the base. It is necessary for air circulation between the thermal insulation and the topcoat.

- Sheathing the crate with wooden clapboard.

Finish the work with the installation of skirting boards and elements for finishing the inner and outer corners.

Ceiling insulation

According to the measurements carried out, up to 35% of the heat goes through the ceiling, since this is where warm air accumulates.

Builders distinguish three technology options:

- False ceiling. A vapor barrier layer is attached to the overlap from below. Mount lags. Place insulation. Cover the surface with waterproofing material. The lining is hemmed.

- Panel. From the side of the attic, logs are installed, forming a box. Laying waterproofing. Expanded clay is poured or panel heaters (polystyrene, basalt slabs) are used, which is closed with steam and hydro insulation.

- Grazing. The easiest option for small buildings. Roll materials are laid on top of the ceiling overlap from the attic side.

Thermal insulation for the sauna ceiling cannot be foam plastic due to hazardous emissions when heated.

Doors

Door frames are the thinnest element in the construction of a bath, a lot of heat is generated through it.

There are several ways to insulate the entrance door to the building:

- installation of an entrance group with two sequentially opening doors;

- warming the canvas with felt, ecowool, isolon;

- installation of the heating circuit on the door frame.

The door to the steam room, as a rule, is not insulated, since it is made of laminated veneer lumber or solid fire-resistant glass.

Correct insulation of the bath will help create a healthy microclimate and save on building materials. Good insulation conserves energy and contributes to long-term heat retention after stove operation.

The bathhouse can only be insulated from the outside.