Most of the heat escapes through the garage door, since the canvases are made of metal with a high coefficient of thermal conductivity. They put a car in the garage, carry out repair work, store household items, tools, spare parts. They provide an acceptable microclimate in the room, protect from the cold, insulate garage doors with penoplex, mineral wool.

- What is garage door insulation for?

- The choice of insulation

- Extruded polystyrene foam (penoplex)

- Polyurethane foam

- Polyfoam with crate

- Mineral wool

- Required tools

- Lathing for insulating garage doors

- Stage-by-stage manufacture of lathing

- Surface preparation

- Waterproofing and laying insulation

- Insulation of gaps

- Sash sealing

- Professional advice

What is garage door insulation for?

According to SNiP 21.02 - 1999, the temperature in the garage should not be lower than + 5 ° C. In winter, the room should be frost-free in order to extend the life of the rubber gaskets of the machine, to prevent corrosion and condensation in the cavities inside the machine.

A protective layer becomes necessary not only in winter, but also in summer. In the heat, the metal flap heats up, transfers heat to the internal air, and heats up so that it becomes difficult to stay inside. In the garage, they sometimes store vegetables, so insulation from the cold contributes to the creation of the required temperature regime.

The choice of insulation

To insulate garage doors, the material is chosen taking into account the thermal conductivity coefficient and the ability to absorb water. If the layer gets wet, it immediately loses its protective properties. For such types, it is necessary to additionally install waterproofing, leave a ventilation gap between the layers.

For thermal insulation are used:

- extruded polystyrene foam (penoplex);

- polyurethane foam;

- Styrofoam;

- mineral wool.

The effectiveness of protection increases with increasing layer thickness. For garage doors, an average of 5 cm is used.

Extruded polystyrene foam (penoplex)

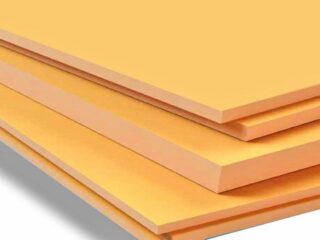

Insulation of garage doors with penoplex will allow you not to think about heat loss for about 50 years, while the panels have a low ability to absorb water. Plates are lightweight, they are produced with a density of 20 - 50 kg / m³. Chemically resistant to atmospheric acids, alkalis, wind protection.

Polyurethane foam

The foam has good adhesion to the vertical surface of any shape of the sash. Additionally, it protects the door surface from corrosion, since it resists the effects of alkalis and acids. Ultraviolet light has a destructive effect on the material, therefore, such spraying must be painted to protect it from the sun, or sheathed on the outside with OSB plates, profiled sheets, plywood.

Polyfoam with crate

Garage doors are insulated with polystyrene foam using a lathing made of wooden battens or an iron galvanized profile. Elements are placed along the perimeter, bottom and top so that the sizes of the cells coincide with the dimensions of the panel and do not have to be cut.

Mineral wool

Mineral wool is sold in rolls and slabs, there are varieties on the market:

- glass wool;

- stone wool;

- slag.

Insulation is produced with a density of 75 - 200 kg / m³. The layer additionally serves as protection against noise, high density sheets protect against fire.

Required tools

The markings for the fastening of the profile, rails, insulation plates are carried out using a tape measure, the length of which should be more than 5 m. Right angles are checked with a construction square.

Prepare tools for work:

- electric drill, screwdriver with a set of drills for metal;

- hammer, pliers, metal brush;

- screwdrivers and a knife on g / cardboard;

- a hacksaw for wooden slats or a grinder for an iron profile;

- primer brush or roller.

You can cut the elements for the lathing with an electric jigsaw with nail files for metal or wood.

Lathing for insulating garage doors

The frame elements are attached to the door frame, for which the details of the crate are cut to size. Wooden slats are treated with an antiseptic, water repellents, so that they are not led away from condensation. The fittings on the sash are trimmed with a profile along the perimeter.

Choose a dry tree, the section of the parts is 20 x 40 mm. The lathing elements are fixed to the canvas frame with self-tapping screws for metal of the required length. A hole is drilled in the iron 0.5 mm less than the diameter of the hardware before tightening the self-tapping screw.

Stage-by-stage manufacture of lathing

Before insulating the gate in the garage with your own hands, mark the squares. Their dimensions are taken according to the size of the insulator sheets. The minimum slat pitch is 400 mm. The elements should not protrude much beyond the plane of the sash so that the canvas has an easy movement. Sometimes the installation diagram of the rails or a drawing helps.

Along the length of the slats, the screws are fixed in increments of 20 cm. To align the plane of the frame, use a lace that is pulled over the extreme elements. Self-tapping screws are tightened with a screwdriver with a cross head.

Surface preparation

The plane of the canvas is cleaned of old layers of paint, the coating is removed from sheet materials, if any. Before work, dismantle locks, handles, bolts, if they are not welded to the canvas. Sometimes there are ventilation holes in the gate, which are sheathed around the perimeter with insulation and a forced ventilation device is installed.

The surface is cleaned from rust using brushes with metal teeth or a grinder with a grinding disc is used. The canvas is treated with anticorrosive agents, then primed with solvent-based compositions.

Waterproofing and laying insulation

To protect against moisture, the door leaf and the frame are coated with molten resin or polymer mastics based on bitumen. Another option is to use a waterproofing film layer. Most often, they put a polyethylene membrane or acquire a material with micropores for the passage of vapors.

Insulation can be laid directly on the canvas, put on the frame. For gluing plates of polystyrene, expanded polystyrene, special glue is used, which is applied to the surface of the plate with dots. The panel is pressed against the sash, it is glued. It remains to fill the seams with polyurethane foam for outdoor use.

Insulation of gaps

It is possible to close the door gaps when insulating between the leaf and the door frame with the help of profile strips. On the sides and on top, metal porches are used, and at the bottom they put a threshold with a protruding shelf. Details protect from wind, dust, snow coat, prevent rodents from entering the garage.

The strips are fixed to the box by welding or self-tapping screws for metal. Lower and upper limiters are placed on the vestibule.

Sash sealing

Seals made of various materials are mounted on the strips from the inside. They are compressed when the sash is closed, closing the minimum gaps.

Types of seals:

- Rubber. A common type, it is inexpensive, differs in a variety of shapes and sections.

- Silicone. It is produced in the form of a tape, it adheres well to various materials, for example, wood, metal, stone.

- Brush. Most often used for sliding gates. The material is treated with a special compound to increase wear resistance.

The polyurethane foam insulator takes on the required shape after installation, so all the cracks are tightly closed for cold and wind.

Professional advice

If there are no ventilation vents in the garage, complete tightness should not be achieved. Lack of fresh air flows will lead to stagnation of the internal atmosphere, the appearance of unpleasant odors, and the formation of condensation.

Instead of a sprayed layer of polyurethane foam, for which you need to rent equipment, use ordinary foam from spray cans. The insulator retains heat just as effectively under the finishing layer.

To maintain a comfortable microclimate, not only the gates are insulated, but also the walls, floor, and coating.