Lightweight and durable polycarbonate has found application in the creation of awnings for terraces, gazebos or canopies of country houses. It has a presentable appearance, is resistant to weathering and is easy to install. When choosing a material, take into account its thickness and color performance.

Features of Polycarbonate Canopy

Building a veranda or terrace in a country house allows you to spend more time outdoors. Among the many extension designs, polycarbonate roof options are especially popular. This design lets in a lot of sunny color, looks light and stylish. The polycarbonate roof for the veranda and terrace is inexpensive and can be assembled by hand.

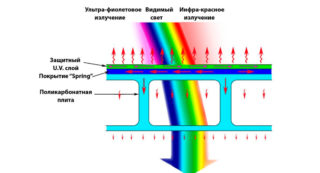

Polycarbonate sheet is a transparent plastic with increased strength and durability. To increase resistance to UV radiation, a special protective layer is applied during manufacture. In terms of light transmittance, the material is comparable to glass, but significantly surpasses it in strength. Polycarbonate is painted in various colors, which expands the design possibilities.

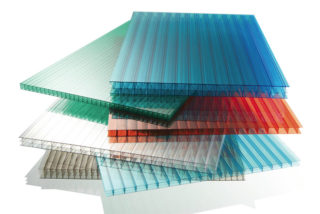

Varieties of material

As a coating for various structures, several types of plastic sheets are used, which differ in appearance and technical characteristics. To decide which polycarbonate is best for installing a canopy, it is worth knowing the features of each of them.

Cellular

Cellular or honeycomb polycarbonate is from two to five layers of polymer plates, between which stiffeners are located. Such a device increases the thickness of the sheet. Depending on the number of interlayers, it is 4-32 mm. The length of the products is 6 and 12 m, the width is 2.1 m. Thanks to the design with air spaces, the weight of the panels is reduced. The common shape of the cells is rectangular, but they are triangular, trapezoidal, etc. The stiffeners between the plastic layers are made straight and inclined. Material advantages:

- impact strength;

- light weight;

- low thermal conductivity;

- durability;

- resistance to weathering.

Air chambers inside the sheet provide sound insulation. When it rains, there will be no noise under the cellular polycarbonate roof. With improper installation, water flows into the internal voids, moisture from condensation can accumulate.

Monolithic

Plastic is similar to glass, it is a monolithic molded panel with varying degrees of transparency. The thickness of the products is 1-13 mm, the length is 605 mm, and the width is 205 mm. The material is difficult to break, so it is used for sheds at stops. Plastic panels are resistant to hail, wind gusts, and withstand snow cover. The flexibility of polycarbonate allows for rounded designs. Also, the advantages of the material include:

- moisture resistance;

- ease of processing;

- light weight;

- high light transmittance;

- the ability to operate at temperatures from -40 to + 120 ° C.

Monolithic panels are produced not only smooth, but also profiled. Corrugated sheets with stiffening ribs are more durable, do not require compensation for thermal expansion. They are made with bright colors, partially or completely transparent.Externally, the products are similar to slate, but have a more aesthetic appearance.

Polymer panels are fireproof products, they do not support combustion. When damaged, the material does not produce sharp fragments that can injure a person. Among the disadvantages of monolithic polycarbonate: instability to scratches and chemical compounds. When installing, it is important to take into account the thermal expansion of the sheets.

Thickness and size of polycarbonate

To determine the thickness of the material, it is necessary to take into account the purpose of the canopy and the expected load. Usually, the structure is installed to protect the porch and the front door from precipitation, serves as a shelter for a car and other household needs. The roof is mounted on supports or fixed to the wall of the building. The design is chosen as simple - single-slope or gable. For a flat roof, you cannot choose panels smaller than 10 mm, otherwise they may crack from the weight of the snow.

A visor with a small radius of curvature is arranged from a panel of 4 mm. For a canopy of a small area or a gazebo with a curved roof, sheets of monolithic polycarbonate 6-8 mm thick or honeycomb two-layer plastic 4-10 mm thick are suitable. The parameter will provide the necessary strength and allow the material to bend without problems to create a rounded structure. In conditions of high wind load and heavy snowfall, a reliable coverage of 10 mm or more is required.

Advantages and disadvantages

Plastic transparent panels are versatile in use. They are used in the construction of greenhouses, in the creation of awnings and in the decoration of facades. The material has many positive qualities:

- Impact resistance - thermoplastic polymer withstands increased stress in all operating conditions. Monolithic panels are anti-vandal coatings.

- Frost resistance - the material becomes brittle at low negative temperatures, but in real conditions such frosts are rare.

- Light transmission - performance parameters from 90 to 25%. You can choose polycarbonate with excellent sunlight transmission or an option with moderate (strong) shading.

- Light weight - the panel has a small load on the supporting structure, so its installation does not require high costs.

- Wide range of colors - a variety of colors and shades of plastic products allows you to create an original architectural image of a terrace or gazebo.

- The large size of the sheets and ease of processing allow for quick installation of the canopy.

The affordable cost and excellent performance of polycarbonate have made it a popular building material.

Disadvantages:

- Scratches easily appear on the surface from mechanical impact during transportation and installation.

- Monolithic polycarbonate is expensive.

The advantages of plastic panels are much greater than the disadvantages that any material has.

Color matching principles

The material is manufactured with different levels of light transmission. For awnings, experts advise taking translucent and opaque products.

First of all, the color depends on the purpose of the structure:

- The carport is chosen in dark shades (bronze, brown) this will prevent the metal from heating.

- For the veranda, opaque opaque panels of milky, smoky, silver or other cold shades are chosen. The material will absorb some of the sun's rays.

- The best option for covering an outdoor pool is blue or turquoise.

- The disadvantage of completely transparent sheets is the strong heating of the space, they can be installed as small canopies above the entrance.

- When installing red, yellow or green polycarbonate, it is worth considering that all objects under such a roof will acquire the appropriate shade.

A special coating protects the plastic from UV rays and helps to partially dissipate them.The color of the coating should be in harmony with the overall architectural appearance. It is desirable that it matches the shade of the roof of the house.

Possibilities of replacing polycarbonate with other materials

Other types of plastic can be used to create a light-transmitting roof.

- Transparent glass fiber reinforced polyester slate can replace polycarbonate in roofing applications. The material is lightweight, moisture resistant, not afraid of temperature jumps. It is offered in rolls with a width of 2-3 m and a length of 40 m. The special shape of the fabric allows you to create a coating with a minimum number of seams. Light transmittance depends on the dyeing of the polyester and is 90-50%. The material can be flat, wavy or profiled.

- Transparent acrylic or plexiglass is a material that is 2.5 times lighter and 5 times stronger than ordinary glass. The plastic is resistant to biological effects, water and frost. It is easily processed, does not turn yellow from ultraviolet radiation. Plexiglas is made transparent or colored with different saturation of shades. The material is inferior in strength to polycarbonate, but it will be cheaper.

An alternative option to plastic for the canopy will be corrugated board. Profiled metal sheets with an outer polymer layer make it possible to create a strong and reliable roof with a long service life. Such a canopy provides protection from the sun and precipitation, and is easy to install. The disadvantages of the material include high noise during rain. The corrugated board does not transmit light, therefore, a shadow forms under such a canopy. Plastic and metal sheets create designs that are completely different in terms of aesthetic perception. The polycarbonate roof is transparent and light, the metal profiled sheet gives a feeling of solidity and reliability. Both coatings have good performance characteristics, so you follow your own preference when choosing a material.

Rules for choosing polycarbonate for a canopy

- Spraying is the least reliable option, its layer is gradually wearing off.

- Extrusion - the coating is soldered to the plastic.

- Adding during production - the stabilizer enters the polycarbonate at the granule stage, evenly mixing with the plastic. This option is the most reliable and expensive.

When deciding which polycarbonate to choose for the roof of a terrace or canopy, several factors are considered:

- sheet specifications;

- design features of the frame;

- wind and snow load in the region.

If the owner wants a roof that resembles glass as much as possible, use monolithic polycarbonate for the canopy. The material is highly durable and is recommended for areas with difficult weather conditions. It bends easily, therefore it is popular for creating curved structures. Cellular polycarbonate is lighter and cheaper, but inferior in strength and service life.

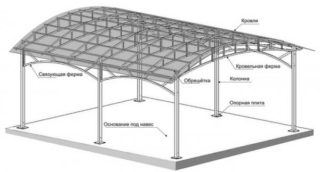

Installation rules

Various types of canopies are built with polycarbonate cover:

- visor over the balcony or front door;

- a structure that protects the car from precipitation and burnout of the skin;

- covering of a terrace, gazebo or veranda, which increases the comfort of rest;

- pool canopy to prevent rain and leaves from entering the water.

By the type of construction, canopies are adjacent to the wall of the house and are free-standing. In terms of shape, a single-pitched or gable, domed or arched roof is most often chosen. Before the start of construction, a drawing of the canopy with all dimensions is drawn.

The frame for the canopy is made of a metal profile or wood. To work with metal, you will need a special tool and a welding machine.A beam with a thickness of 100 × 100 mm is used as supports, for a lathing of 100 × 50 or 70 × 40 mm. After assembling the frame, proceed to the installation of plastic panels. Work requires compliance with the following rules:

- To connect the sheets, a special profile with a threaded connection and a snap-on cover is used.

- The ends of the panels are closed with punched tape, and then with an end profile in the shape of the letter "P". This will give the structure a neat look, and the cellular polycarbonate protects against moisture penetration inside.

- The plastic is fixed with self-tapping screws with a thermal washer. The fasteners are loosely tightened, a gap of 1-2 mm is required for thermal expansion of the material. The self-tapping screw is screwed in strictly perpendicularly, without squeezing the material.

- The hole for the fasteners cuts 2-3 mm larger than the diameter of the self-tapping screw in order to neutralize the change in the parameters of the plastic with temperature drops. A rubber washer closes the hole and ensures a tight seal.

- On polycarbonate sheets, it has a film that protects a layer that protects against ultraviolet radiation. It must be outside during installation. It is removed after the end of installation. During work, they are partially pushed back to secure the sheet.

- When installing a pitched roof, a slope of 6 ° is recommended so that the condensation inside the cellular polycarbonate can drain outward. To remove it, holes are made in the end profile.

A polycarbonate canopy with a proper choice of thickness and professional installation will last more than 10-15 years. The material is easy to care for, keeping it clean and attractive. Due to its lightness, heat and sound insulation characteristics, plastic will be the best choice for covering terraces and gazebos.

Good hail and this cover skiff

I have negative experience, maximum 5-7 years and that's it, hail, and also birds, plus specials. Washers start to leak. I have 8mm on a flat roof. I will take pictures. Change to metal, if polycarbonate, then only monolithic wavy.