Despite the wide selection of modern flooring, wood continues to be at the height of its popularity. The material of natural origin has a lot of positive characteristics. Both solid board and parquet are distinguished by presentability, low thermal conductivity, pleasant tactile sensations, ease of installation and maintenance. However, the tree is susceptible to external factors. Due to vertical pressure, temperature and humidity changes, it changes volume and deforms. Such phenomena often occur, but are not a reason for replacing the coating. There are many ways with which you can level a wooden floor in a private house with your own hands.

Determination of the condition of the floor in a wooden house

The reasons for repairing plank flooring can be very varied. Most often, owners of private real estate have to deal with creaks and knocks, curvature of floorboards in length and width, height differences between fragments, cutting the eye with a multi-layer paint and varnish coating.

In all cases, the work must be carefully planned and prepared.

The necessary information can be obtained by conducting diagnostics, which includes the following activities:

- Visual inspection. Determination of the condition of the topcoat, the possibility of its further operation.

- Measurement of differences in height and degree of curvature of floorboards. If the indicators exceed 2 cm, it is necessary to level the surface. The ledges will interfere with the movement of furniture on casters and tear the socks.

- Checking the condition of the array of boards and logs. The reasons for the overhaul are areas of rot, mold and mildew, the presence of moves made by parasites.

To get a complete picture, you will have to remove some of the coverage. This must be done carefully in order to return it to its place without any problems.

Alignment methods

Uneven flooring negatively affects the presentability of the room. In the presence of serious hidden defects, the panels can break at any time under a person or under an element of the interior. Therefore, there is no need to delay with the restoration of the boardwalk.

Depending on the results of the survey, one of the following methods is selected:

- Looping. The option is used if the wood has not undergone pathological changes, there are bulges, several layers of paint, but there is no need to disassemble and change the overlap. The essence of the procedure consists in removing the top layer, followed by filling the cracks and finishing polishing. It is carried out using manual or professional equipment that can be rented.

- Sheet material. It is used when the surface is flat, but the coating is so deformed that its restoration is impossible or economically impractical. In such cases, the old flooring is used as a rough base, but it is pre-strengthened in order to exclude later knocks and squeaks. Materials such as OSB, chipboard, cement-bonded particle boards and gypsum fiber sheets are used as coatings. The fastening is carried out rigidly - on long self-tapping screws. After covering the entire surface, the gaps are closed and polished.

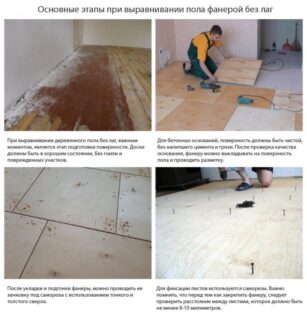

- Plywood on logs. This technology is used when there are strong drops in excess of 2 cm.In such cases, the old flooring is used as a foundation for new masonry. Initially, the zero level is determined, lags are set on it. The thinner the plywood, the smaller the interval between them. It is better to cut it into squares so that there are more joints that provide thermal expansion of the material. A backing should be glued between the lags and the coating to avoid extraneous sounds.

- Screed. The decision to pour the mortar over the flooring is made when it sags so much that all that remains is to tear off the floorboards, logs and carry out a complete overhaul. It is long, expensive, it is easier to solve the issue locally - to fill the bent place with a gypsum or polymer mixture. First, you need to close up the cracks and clean the coating from dirt.

If the boards are free of defects, you do not need to level and remove them, you can restrict yourself to putty. Used compositions of factory or self-made. To make the flooring look uniform, a dye of the appropriate shade is added to the grout.

Required tools and materials

Leveling the floor in a wooden house can be carried out in various ways, which is associated with the peculiarities of both the coating itself and the conditions of its operation. Based on this, you need to be prepared for the fact that you will have to purchase a full set of equipment for all types of restoration work.

To restore uneven floors, you will need tools:

- scraper (planer, belt grinder) machine;

- level;

- roulette;

- electric drill;

- puncher;

- nail puller;

- a hammer;

- silicone spatula;

- screwdriver;

- paint brush.

From the materials you need to purchase:

- sandpaper;

- substrate;

- glue;

- antiseptic;

- primer;

- grout for joints;

- containers for mixing the solution and washing tools;

- paint.

To maintain safety precautions and prevent injury, work with gloves, glasses and a gauze bandage.

Features of leveling the floor

If an uneven floor is restored by scraping, you should pay attention to the following points:

- All protruding metal parts must be removed or sunk below the level of the flooring by 2-3 mm.

- You should purchase several attachments with different grain sizes in advance. The largest ones remove the top layer of the coating and make it smooth, the smallest ones bring gloss.

- The first run with the machine must be done in the direction along the fibers. The stripes are made with an overlay one third of the previous one. Then the direction changes and the device must be moved across the floorboards.

- It is recommended to change the nozzles regularly, as they wear out. Erased fragments reduce work efficiency.

- When manipulating the equipment, it is necessary to observe the smoothness of movements, avoid sudden jerks, accelerations and downtime.

Recommendations for high-quality leveling of the floor in a wooden house with sheet material:

- Use rigid boards with a minimum thickness of 12 mm. Soft materials such as hardboard and foam are not suitable, as they take the shape of the base. If only thin plywood is available, it is laid in 2-3 layers, each offset by a third of a square.

- Self-tapping screws should be used to fasten the new flooring. Nails can split the slab and cause cracks.

- It is possible to form a new level with the help of fields made of screws screwed in one zero level at a time.

- The base must be made in the form of a lattice so that there is support for all the edges of the plywood squares.

- It is recommended that the used spacers be nailed to the joists and the floor so that they do not move during the installation process.

- It is necessary to leave a gap of 3-5 mm between the boards for thermal expansion. The cracks are rubbed with silicone sealant.

When self-leveling mixtures are used, the following factors are taken into account:

- Gypsum is lighter, dries faster, but cement compositions are much stronger, the layer can be made thinner, although their hardening period is longer.

- The reinforcing mesh is nailed to the floor in such a way that it is from its surface at a height of 3-8 mm, depending on the thickness of the screed.

- Even a smart self-leveling screed needs to be rolled with a needle roller to remove air bubbles from it.

- The use of impregnation strengthens the composition, prevents dust formation and improves adhesion to the finish.

With the correct organization of work, it will not be difficult to level the old boardwalk without expensive procedures for dismantling and replacing it. It is only necessary to conduct a competent analysis of the situation, choose the optimal technology, carefully and without haste to perform all the necessary actions.