Previously, slate was one of the most common roofing materials. With proper installation, it can serve for more than a decade, however, under the influence of external climatic and mechanical factors, it gradually collapses, which leads to the appearance of various defects on the surface. Some of them can be removed on site, while others may require a major overhaul of the roof.

Causes of defects

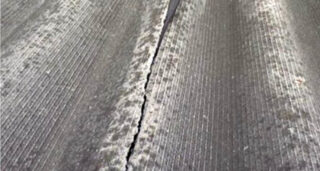

Theoretically, the service life of slate is more than 15 years, but in practice it requires repairs much earlier. After 10 years of operation, cracks, holes, deformations appear on the roofing sheets. The reasons:

- Low impact strength - damage to the slate can be caused by a branch falling from a nearby tree, a stone being thrown, or a person walking on a roof.

- Biohazard - atmospheric precipitation cannot damage the slate, however, it contributes to the rapid development of moss, fungus, lichen and other types of protozoan bioorganisms. Their colonies are firmly fixed on the rough surface of asbestos cement, while destroying the structure of the material and creating water congestion. This in turn increases the likelihood of leaks.

- Aging - slate is subject to these processes, like other building materials. For example, a slate roof can withstand about 30 cycles without changing the operational parameters, after which the water resistance and strength gradually begin to decrease.

- The installation of the roof was made with mistakes - the slate sheet can crack if it is too rigidly fastened to the crate. The appearance of cracks can also be caused by the wrong choice of fasteners - the use of ordinary nails instead of special roofing nails.

- Careless transportation and improper storage of slate leads to the appearance of microcracks that are difficult to notice. However, they can make themselves felt with any impact on the sheet.

- The wrong choice of the angle of inclination of the roof - slate sheets laid on the crate will experience excessive stress and eventually crack.

The roughness of the slate does not visually detect small defects on its surface, due to which the sheet can become unusable at any time. Therefore, they are looking for them by accompanying signs.

Defect search methodology

There are not so many visual ways to identify damaged slate sheets. There are places where defects occur most often:

- the edges of the cornice, which are clearly visible from below;

- the crest of a wave of a slate sheet, into which nails are driven.

The roof can be viewed from the attic side. Any damage to the slate manifests itself as a leak. On the inside of the leaf, wet dark spots are clearly visible in cracked places. If water drips from the slate sheet, this is a clear sign of a defect.

How to close up the cracks and holes in the slate

Before proceeding with the repair of the slate roof, you need to determine which defects can be eliminated, and which ones will require replacing the damaged sheet with a new one.

If the sheet is badly cracked in the transverse or longitudinal direction, it makes no sense to seal it up - after a while there will still be a leak.If a small defect is found, then it is repaired using one of the known methods.

On a slate roof, a special ladder or boards laid across the waves are used for movement.

Repair of slate begins after thorough cleaning of the damaged areas from debris and dirt.

Butyl rubber tape

The use of self-adhesive butyl rubber tape for sealing defects is considered one of the most effective ways to repair slate. This non-woven waterproof material is used when it is necessary to seal the joints of the roofing material with walls, pipes, etc.

Repair work procedure:

- The surface around the detected damage is degreased.

- A piece of tape is prepared, the dimensions of which will allow to overlap the contour of the damaged area by 5-10 cm.

- Gradually removing the plastic film that protects the adhesive layer, the sealing tape is carefully applied to the damaged area.

- After the tape closes the crack along its entire length, it is painted with a water-repellent paint.

Large cracks are additionally reinforced with a serpyanka tape made of fiberglass. In this case, a butyl rubber tape with a double-sided adhesive layer is used.

Repair process:

- Double-sided self-adhesive tape is applied along the entire length of the crack.

- Carefully peel off the protective film from the top adhesive layer.

- Lay the serpyanka tape.

- One-sided butyl rubber tape is glued on top.

The patch is painted with water-repellent paint.

Hot bitumen and bitumen mastic

Hot bitumen is used to seal cracks in slate. The best option is to lay two layers of roofing material with their preliminary coating with hot bitumen. The latter is also applied over the patch.

At present, bitumen mastic is more often used instead of hot bitumen. They do it as follows:

- After cleaning the damaged surface from dust and dirt, bitumen mastic is applied to it with a brush.

- A serpyanka tape is laid on top of the mastic layer and smeared with bituminous mastic.

- Apply two layers of roofing material, having previously coated them with bituminous mastic.

- Mastic is also applied to the top layer of roofing material.

If necessary, the number of layers of roofing material can be increased, but this contributes to the occurrence of water congestion.

Polyurethane foam and epoxy

Slate sealant in combination with polyurethane foam and epoxy resin allows to reliably seal the damaged part of the slate. However, this can only be achieved by observing the following sequence of work:

The edges of cracks or holes are filed, after which the damaged area is degreased.

From the side of the attic, the lining is laid under the damage and securely fixed. Insufficient fastening will lead to the fact that the expanding foam will push the latter and the seal will be broken.

- Fill the crack or hole with polyurethane foam.

- When the foam dries, the excess is carefully cut off.

- A slate sealant is applied to the damage, which should fill all the pores in the dried polyurethane foam.

- After the slate sealant has dried, epoxy is applied to the patch. At the same time, it should close the crack with itself, blocking its edges by 2-3 cm.

It is allowed to use special waterproofing compounds of the coating type for the repair of damaged slate, in the manufacture of which mixtures of cement and polymers are used.

Cement-sand mixture

To seal defects, use a mixture of fine sand and cement M500 in proportions 1: 2.

Repair a small crack or hole (hole) as follows:

- The slate surface around the damage is moistened with water.

- The damaged area is covered with the prepared repair mixture and leveled in thickness. A thick layer of grout can contribute to the formation of water mash.

- As soon as the "patch" dries, it is primed, and after drying, it is covered with waterproof paint.

If the area of damage is large enough, then it is necessary to lay the lining from the side of the attic, having previously given it a waveform.

Nitro-based moisture resistant adhesive

When using moisture-resistant nitric glue to seal defects on slate sheets, most of the work is done in the attic. The detected defective area is degreased, and the edges of the damage are coated with glue. Then they take a strip of fabric, the width of which exceeds the width of the damage by 10-12 cm, treat it with glue on both sides and apply it to the defective surface. After the slate glue has dried, the cracks and holes are covered with a sand-cement mixture from the side of the roof.

Asbestos-cement sheets are extremely sensitive to temperature changes, therefore, during repairs, high-temperature melts based on ceresin, resin and basalt powder cannot be used. It is also not recommended to use epoxy compounds and clean resins. In severe frosts, these materials become cracked and gradually peel out from the seams.

The roof of slate sheets is protected from destruction by applying a special primer, followed by painting the roof with rubber paint, which creates a layer of elastic waterproofing.