The installation of a staircase is part of the arrangement of a house with two or more floors, equipped with a basement or attic room. Structures are made from different materials and are designed taking into account the purpose.

- Varieties of stairs

- Marching

- Screw

- Complex constructions

- Staircase fixing options

- To the floor

- To top floor slab or beam

- To intermarch sites

- To the walls

- Requirements for interfloor stairs

- The choice of material for the manufacture of stairs

- Wood

- Metal

- Concrete

- Required tools and materials

- DIY installation features

- Made of metal

- Made of wood

- Concrete

Varieties of stairs

There are several basic types of staircase structures. When choosing a suitable design, space constraints, as well as ease of use, are taken into account.

Marching

This is the most common option: the design can include one or more marches separated by platforms. In private houses built of wood, it is usually practiced to install stairs from the same material. A product with one flight can only be attached to the ceiling and floor. But sometimes additional fixation methods are used. When there are several marches, a platform is necessarily organized between them.

Screw

Due to their compactness, such products are installed in narrow openings. However, for certain categories of people (young children, people with a susceptible vestibular apparatus or with impaired functioning of the musculoskeletal system), they are highly likely to be uncomfortable. Stringers, post structures, bolts or bowstrings can act as supporting elements. Usually a combination of several options is used.

Complex constructions

This includes stairs with a fragmented structure, including sections with a different structure. This can be a combination of screw-like parts with flights, or several of the latter, which have an unequal value of the angle of rotation.

Staircase fixing options

The structure of the staircase involves a combination of several fixing methods, selected according to the design features.

To the floor

Any ladder other than an extension ladder will need to be nailed to the floor. The choice of fasteners depends on the materials from which the coating and the structure itself are made.

To top floor slab or beam

Fastening the stairs to the ceiling to the second floor is also a must. Most often, fixation is made to a reinforced concrete slab or to a ceiling equipped with wooden beams. Steel beams are not common in the private sector. A simple one-marching structure is attached from below to the floor, and from above to the ceiling.

To intermarch sites

This option is practiced if the staircase includes more than one flight or is a complex configuration consisting of several lifting areas connected by platforms. When designing the latter, it is important to correctly calculate their dimensions.

To the walls

Such anchoring is used as a supplement to the floor and ceiling connection. The supporting wall should be thick enough (at least 0.25 m) and made of durable material - brick, reinforced concrete or high-quality timber. In no case should the structure be fastened to a plasterboard or asbestos-cement wall. Masonry in one brick is also not suitable.Fixing to the wall necessarily requires screw structures, even if they are equipped with only one turn. If there are two of them, in addition to connections to the floor, ceiling and wall, an additional support in the form of a pillar is required.

Requirements for interfloor stairs

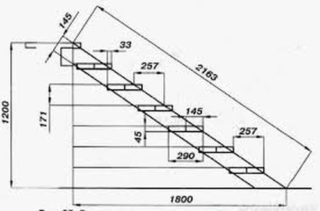

Before starting the installation work, you need to prepare a drawing of the future structure. It depicts all structural elements with their dimensions. The following requirements are imposed on the dimensions of individual parts:

- The width of the step should not be less than 25-27 cm, otherwise moving along the structure becomes traumatic.

- The minimum width of an interfloor staircase is 0.9 m. It is better if it is larger, especially if the homeowner plans to move large objects to the upper room.

- The steps should be 15-20 cm high.

- In residential premises, the slope can be 40-45 degrees, for mansard and attic it is more pronounced (60-70).

If the number of steps is four or more, you can equip the structure with a railing part. Its height should be at least 90 cm. All parts of the system (if they are not made of refractory raw materials) should be treated with flame retardant impregnations.

The choice of material for the manufacture of stairs

Often, the structure is made of the same material from which the walls of the building are made. Each type of raw material has certain restrictions on its use.

Wood

Installation of a wooden staircase is recommended for two-story private houses. It is also a good design option for descent into the basement (provided that the air in it is not very humid). Fire safety rules do not recommend installing wooden stairs in houses with more than two floors. This is due to the fact that in case of emergency incidents, it should be easy for residents to go downstairs before the structure burns out. It is recommended that all elements of the product be made of wood of the same grade and degree of processing - this will reduce the likelihood of squeak and deformation during operation. The raw materials used must be well dried. In order for the structure to serve for a long time, heaters should not be placed near it. It is also important to protect it from excessive moisture ingress.

Metal

The most suitable raw material for stairs is thick stainless steel. Other types of metals are also used, but they have disadvantages: cast iron is heavy, and chrome-plated steel does not last so long, although it has an expressive texture. Sometimes the surface is finished like marble using a special powder composition.

Concrete

Reinforced concrete structures are usually installed in buildings constructed from the same material. The surface of such a staircase can be finished with natural or artificial stone. However, some types of such coatings are slippery. In this case, a film is mounted on the steps, leveling this effect.

Required tools and materials

For a structure made of wood, you will need to prepare bars with a minimum thickness of 5 cm, from which the braids are made. Their length should cover the entire length of the march (two elements cannot be fastened together). You will also need boards for mounting steps. For the horizontal part, their thickness is 4 cm, for the vertical part - 3. It is important to prepare the parts for fasteners. Zinc-coated self-tapping screws, anchors and screws are commonly used.

A hammer and a chisel are prepared from the toolkit to create grooves, a plane and an electric drill. You should purchase a screwdriver, by means of which structural elements are fastened to each other.

DIY installation features

Before starting work, you need to decide where the structure will be fixed, and prepare suitable fittings. Drawings are also created indicating the dimensions of all elements.

Made of metal

First, a metal frame is created.By fixing it, you can install the stairs. If the base of the house is made of concrete, the lower supports of the stringers can be mounted directly in it. Fillets are made of corners, and kosoura are made of metal profiles with a square section. The steps are connected to the base by welding.

Made of wood

The beam used for the manufacture of stringers is cut to the planned length of the structure. A fragment with a tread thickness is removed from below. Further

- In the stringer, they cut a place for the steps using a square.

- Apply the workpiece to the installation site. The top should be flush with the finished second floor flooring. The lower part rests on that of the first.

- A second stringer is created on the basis of the workpiece. Then the details are carefully sanded.

- Cuts are made in the upper and lower parts, and the stringers are connected to the massive beam (and to the wall, if planned). At the same time, they are fixed to the anchor.

- The horizontal and vertical components of the steps are cut out of the boards. Then they are polished.

The blanks are attached to the base using self-tapping screws. After that, you can install the railing.

Concrete

Work begins with the preparation of a sand and crushed stone platform, where the stairs will be mounted. Then the formwork is installed. Reinforcement components are laid along the march and load-bearing transverse parts. Pour concrete mortar from the bottom step. It is allowed to remove the formwork after at least three days have passed since the end of the pouring.