The method of construction of residential buildings and ancillary real estate from porous materials is at the peak of its popularity today. At the same time, most of the craftsmen choose pitched types of roofs for their structures. This design is distinguished by a presentable appearance, the best efficiency in terms of wind and snow resistance. The construction of a roof involves the arrangement of a rafter system, which requires strong and reliable support. Such is the Mauerlat, made from a wooden bar. The part takes on vertical loads and distributes them evenly along the walls. During the construction process, you can save a lot and reduce time if you attach the roof to the gas block without preliminary installation of the armored belt. To do this, you need to familiarize yourself with the technology and rules of such a solution.

What is the Mauerlat and its device for?

The Mauerlat is an integral part of the roof structure when the rafter system is used. Inclined beams need support, and for this, walls are not suitable, since they do not have the necessary strength to hold fasteners under high pressure. In addition, the timber installed along the perimeter of the structure provides uniform pressure along its entire length. This prevents individual masonry stones from breaking or breaking. Competently designed and correctly executed laying of the Mauerlat on aerated concrete blocks ensures the stable position of the walls, preventing them from moving apart under the pressure of the rafters.

In the case of erecting a frame made of wood, the Mauerlat is made from a bar with a cross section of 100x100 mm to 200x300 mm, depending on the thickness of the walls and the structure of the roof frame. Docking is carried out by a lock connection with the fastening of the nodes with nails, pins or self-tapping screws. The wood is laid on roofing material after treatment with an antiseptic and a hydrophobic agent.

If the rafters are made of metal, a channel, rail or I-beam is installed under them. The joints are connected by welding, followed by the overlay of fittings with through fixation with bolts.

Properties of aerated concrete

Foam concrete blocks have a wide range of applications in residential and industrial construction. This is due to the unique properties of the material, which combines the positive properties of brick and wood. Aerated concrete has its own advantages and disadvantages, which must be taken into account, both when erecting walls and when arranging a roof.

Blocks have the following features:

- large dimensions, due to which the laying is carried out accurately and quickly;

- perfectly smooth edges and planes, which makes it possible to save on glue;

- low thermal conductivity, close to coniferous wood;

- lightness of the material that does not exert a significant load on the foundation;

- hygroscopicity - high-quality waterproofing is required;

- fragility, instability to vertical and horizontal loads.

Given these properties, many craftsmen prefer to lay the Mauerlat on a gas block with an armored belt, thereby eliminating any complications. However, there are precedents when deadlines are running out or there are not enough funds to manufacture a reinforced concrete contour.In such cases, you can use one of the proven methods by which it is allowed to mount the Mauerlat to a brick wall without an armored belt.

Features of the armopoyas design

Armopoyas is a kind of reinforced concrete foundation for the roofing system. This structure is heavy and is subject to strong wind, snow and tensile loads. Based on this, the roof needs a strong, powerful and stable support that can withstand the influence of external factors for decades.

Armopoyas has the following device:

- Formwork. It is made removable or non-removable. The first option involves the arrangement of a cold attic, in the second, insulation (polystyrene, basalt wool) is used as a formwork.

- Steel frame. Provides contour integrity and flexibility. Consists of fittings, square frames and corner pieces. The parts are fastened using a knitting wire.

- Concrete. Gives the structure strength and form constancy. It is made of crushed stone, sand and cement in a ratio of 3: 3: 1.

- Embedded parts. Serve for mounting the Mauerlat. Pins or studs are used.

The width of the armopoyas corresponds to the parameters of the wall or is taken 5 cm narrower. The minimum height is 15 cm.

Methods for attaching the Mauerlat to aerated concrete

Mauerlat on aerated concrete without an armored belt can be fixed in several ways. Each of them has its own characteristics and order of implementation.

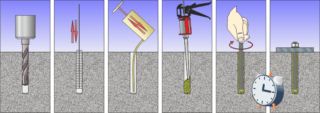

The most common are the following:

- With the use of wire. A twisted wire with a thickness of at least 6 mm is used. The opa is attached to the wall to be erected before laying the last two rows. The step is half the distance between the rafters. After placing the support bar, the wire is wrapped around it, and subsequently around the rafters.

- Fastening with hairpins. Products with a length of at least 80 cm are used. Holes are drilled in the blocks in accordance with the pitch of the rafter legs. Then they are filled with glue and the studs are immersed. The next step is to carry out measurements, make through holes in the Mauerlat and install it on the walls. Finally, the support bar is attracted to the base with nuts.

- Chemical anchors. Here, to fix the studs, a liquid injection mass is used, capable of impregnating aerated concrete to a great depth. Thanks to this, holes in the walls are made for just one block with a small grip of the previous one. The grooves are filled with glue, studs are inserted. Crystallization occurs in 20 minutes after which waterproofing and installation of the support bar can be carried out.

- Anchor bolts. Products of a standard spacer design are used with a length of at least 60 cm.First, the Mauerlat is laid, then holes are made through it with immersion into the wall by at least 50 cm.Then anchor bolts are inserted into them and tightened. The advantage of this method is its speed and affordable cost.

When choosing a mounting method, factors such as wall thickness, weight and type of rafter system, and expected wind and snow loads should be taken into account.

Mounting the Mauerlat on aerated concrete without an armored belt is possible when arranging a pitched roof, where there is no bursting load on the walls. You can also abandon the armopoyas in the case of using hanging rafters in the roofing system. Structures of this type create only vertical loads, which the Mauerlat distributes evenly along the perimeter of the building.

Do-it-yourself technology

Installation of a support bar on foam blocks is carried out in the following sequence:

- Carrying out measurements, drawing up a project, estimates, purchasing materials.

- Manufacturing of a fastening system between the wall and the Mauerlat.

- Arrangement of waterproofing.

- Installing a support bar and carrying out its processing from dampness.

When laying the Mauerlat, you need to pay attention to the joints, they must match the fasteners in the wall.

Probably they wanted to say when using layered rafters. Because the dangling ones have a thrust.

Forgot about plastic dowels to hold very well in the gas block

How many last rows of expanded clay block (structure 6x8 in half a block) must be tied to the Mauerlat so that the roof is not subsequently blown away like a sail? The roof is gable with an angle of 30-40 degrees.

Take a drill, about 32mm (not critical) and drill to a depth of three blocks. Then flush the hole from the gas silicate dust with a hose, dipping it into the hole and wait for the water to be absorbed or make a small side hole for drainage. Tighten a few nuts on the hairpin. Pour in liquid solution and immerse the stud with nuts. After drying, tear off only with a meter-long piece of the wall.