Brick fence posts combine practicality with a presentable look. They provide reliable and durable support for the fence, do not require maintenance during operation. When choosing a building material, it is necessary to take into account the brick manufacturing technology and decorative characteristics.

Features of types of bricks according to manufacturing technology

High-quality brick has high strength, durability, frost and moisture resistance. All these qualities are necessary for a material that is constantly exposed to weather conditions. Product performance is dependent on manufacturing technology. The following types can be used in the construction of fences:

Ceramic

The most popular building material is made from clay, acquiring a characteristic reddish-brown hue after firing. It is produced by semi-dry pressing or plastic molding. There are two types of bricks:

- Corpulent - used for masonry of load-bearing structures, voids do not exceed 13% of the volume. The blocks are highly resistant to frost and bending strength.

- Hollow (slotted) - voids reduce the weight of the block and its cost, increase the thermal insulation properties. The downside is the decrease in strength.

The advantages of ceramic blocks are: environmental friendliness, resistance to frost and mechanical damage, low water absorption, a variety of sizes, ease of masonry.

Silicate

White fence bricks are autoclaved from a mixture of quartz sand and lime. It does not differ in size from ceramic, it can be single, one-and-a-half and double. The material has a high density and strength characteristics, compatible with any masonry mortar.

With the help of pigments, silicate blocks are painted in various colors, they can have a smooth front side or with a textured relief. When facing work, the best option is products with rounded edges. In terms of moisture absorption and frost resistance, the material is inferior to ceramic bricks, but it is cheaper. A sand-lime brick fence is not recommended to be installed in regions with high humidity and frequent temperature changes.

Hyperpressed

Artificial stone is popular for construction and cladding work. It is made from a mixture of granite screening, limestone (shell rock) and cement. The solution without firing is pressed in molds under a pressure of 20 MPa, it takes the form of a monolithic block of high density. In terms of its performance characteristics, it surpasses the silicate and ceramic counterparts:

- strength M150-400;

- frost resistance - F50-200;

- water absorption - 5-8%.

The parameters of hyper-pressed bricks are close to those of natural stone. It has excellent adhesion to the mortar, allowing you to create reliable structures. One of the features is the variety of the front surface, among the models there are many options for torn and chipped stone.

The disadvantages of the material include significant weight, the possibility of cracks due to thermal expansion and color fading.

Clinker

When choosing which brick is best to use for fence posts, many home owners prefer the clinker option. The material is made from special refractory clay, the products have various rich shades of red, cream and brown. Its advantages are:

- increased brand strength;

- frost resistance up to 150 freezing cycles;

- the minimum indicator of water absorption.

The clinker is made with different decoration of the front side. It can be smooth matte or glazed, with a relief application by the gunning method. Buildings from clinker blocks do not lose their attractiveness for up to 100 years. The only drawback of clinker is its high cost, but a small amount of material is required to build the pillars.

How to choose a brick for a fence

At the stage of selection, the decorative and operational characteristics of the material are taken into account. A thoughtful approach allows you to create a beautiful and durable fence at an optimal cost.

The material is building and facing. In the first case, slight chips on the surface are allowed. Ordinary brick can withstand a high load, but it does not differ in external attractiveness. It is used in the construction of pillars, but the masonry needs to be plastered to give it a neat look and protect it from moisture. This material is recommended for a limited budget.

Facing blocks do not require additional finishing. Products are produced with clear geometry and have excellent decorative properties. Any type of brick can be used for facing: ceramic, clinker, silicate or hyper-pressed. The material is divided into two types:

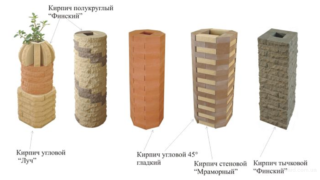

- textured - with a standard form, it receives a relief surface;

- shaped - blocks of complex configuration.

The nature of the front surface of the products is selected based on the requirements for the architectural appearance of the fence. It can be smooth, rusticated, chipped, torn, grooved. The most popular texture options: marble, wild stone, rock, chipped. Decorative bricks for the fence are offered in a wide range of colors.

Another criterion is solid or hollow brick. A monolithic block is more reliable, but at the same time heavier. The version with technical voids has a sufficient margin of safety for the construction of a pillar. Its advantage is less weight, respectively, the load on the foundation is less.

A variety of options allows you to find material for creating a harmonious architectural composition of the house and the fence.

Signs of quality bricks

In order for the fence to serve for decades without losing its attractiveness, it is necessary to choose high-quality material. It is recommended to purchase bricks from manufacturers' factories, where quality standards are monitored. German companies rank first in the rating of clinker brick manufacturers. It is better to buy ceramic and silicate blocks from domestic manufacturers. Any seller should ask for a certificate of conformity for the product. It is necessary to independently check the offered products. What to look for:

- When buying ceramic bricks, the blocks are inspected for cracks formed during firing. The smaller their number, the better the product is. It is also worth taking a closer look at possible inclusions of lime. They are grayish in color and are visible on a red surface. The inclusions react with water to form ruptures. The color of the products is also important: a pale color indicates insufficient firing, and the dark brick was overexposed in the oven. The traditional way to check quality is to hit the block - if the sound is ringing - good, deaf - the technology is broken.

- Sand-lime bricks should have even edges and corners, and the sides should be free of cracks and chips. On the surface, defects, inclusions of unextinguished silicate mixture are not allowed.

Quality material is the basis for the durability of any building.It is easy to work with, the minimum amount of solution is consumed, the result obtained meets expectations.

Calculation of the amount of material

At the design stage of the fence, its plan is drawn, where the key elements are marked: pillars, spans, foundation. A common base option is a monolithic tape. For the installation of spans, a metal profile is suitable. To calculate the fence brick, you need the following data:

- post height;

- the number of posts in the fence;

- type of masonry - one and a half or two bricks.

The height of the pillar is chosen according to the general design solution of the fence, usually it is 2-2.5 m. For one row, when laying in one and a half blocks, 4 pieces are required, in two - 6 pieces. Calculation example for a 2 m post:

- 2: 0.065 (standard brick height 65 mm) = 30.7 rows

There are 1 cm seams between the rows, their total number is subtracted from the design height of the post:

- 2-0.3 = 1.7 m

Number of brick rows:

- 1,7:0,065=26

Knowing that there are 4 or 6 blocks in one row, we get:

- 26 × 4 = 104 pieces

- 26 × 6 = 156 pieces

It remains to multiply the amount of material for one pillar by the amount provided for the construction of the fence.

Decorative brick posts are a versatile option for a stylish and reliable fence. They are harmoniously combined with various options for filling the spans: forged elements, euro bars, corrugated board, board. When choosing a building material, it is worth considering its performance and the climatic conditions of the region.