Using profiled sheet steel for cladding is a simple and inexpensive way to create a reliable fence. This design can last 20-30 years, reliably protecting the site from the gaze of strangers. In order for the fence to be durable and not to have to be repaired soon after installation, it is important to choose the right size of the profiled sheet for the fence.

What is corrugated board

The building material is made of galvanized steel and is produced in sheet form. It is intended for external cladding of surfaces, protection of premises from weather factors, arrangement of roofs and fences. On the roof, the products are laid on a lathing frame with an overlap. Stronger grades of corrugated board are also used to create interfloor floors.

In the production of the material, the technology of cold forming is used. As a result of this process, the surface of the products becomes wavy. The material is in great demand due to its strength, long service life and resistance to external environmental influences.

When planning to purchase steel sheets, it is necessary to determine the future size of the fence made of corrugated board, as well as the dimensions of the spans and other design features of the fence.

Parameters of corrugated board for a fence in accordance with GOST

The standard parameters of the sheet used for the installation of fences are given in GOST 24045-94, which regulates the most common standard sizes of products. It is also indicated there that the price of the product depends on the characteristics of the steel used for the production, the type of protective coating, as well as the thickness of the corrugated board.

One of the main parameters is the width of the profile sheet for the fence. In GOST, it is customary to indicate 2 values of the indicator. The first shows the usable width, the second shows the overall clearance.

Features when choosing a corrugated board

Profiles are often marked with the letters A or R. For the fence, the first type is better. It is painted on only one side. In addition, products are divided into the following categories according to their purpose:

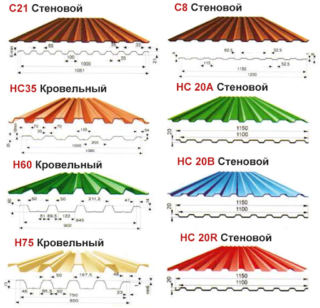

- Wall products are characterized by a small corrugation height (0.8-4.4 cm). They are used for the installation of fences, as well as for wall cladding and the creation of lightweight roofs. In the marking, belonging to this type is indicated by the letter C.

- The bearing profiles have a high corrugation (4.5 cm and more), and are also supplied with additional stiffeners. They are marked with the letter N. They are used to create awnings, roofs, interfloor floors, as well as for the installation of formwork, which is not planned to be removed after the concrete has hardened.

- An intermediate version, a universal profiled sheet, is marked with the letters НС. It has medium corrugation heights and can be used for various purposes, including the creation of roofs and fences.

In a region characterized by windy weather, it is better to choose a universal profiled sheet for fencing - it is more durable and stable than products with a low corrugation height. Another important parameter in such conditions is the thickness of the metal profile for the fence. The larger it is, the stronger the sheet holds. The minimum allowable indicator is 0.6-0.7 mm. It is not recommended to make a fence from thinner products. For windy areas, the thickness should be greater.

Basically, sheets are produced with two types of coating. Products made from galvanized steel will last 30 years.The service life of sheets with a polymer coating is even longer - it has every chance of standing for half a century.

Alphanumeric markings are printed on the product packaging to identify its characteristics. For example, the code C25-0.6-850-11000 stands for wall corrugated board with a corrugation height of 25 mm, a thickness of 0.6 mm, a width of 85 cm and a length of 11 m.

Dimensions of popular brands of metal profiles for a fence

Before buying sheets for fencing, you need to decide on the size of the fence from the profiled sheet. Most often, products with a length of 106, 120, 230 or 600 cm are found. Sometimes manufacturing companies can prepare a sheet of non-standard length if the customer makes such a request. The width of the product, as a rule, is at least one meter.

Fences are made from sheets of wall and universal types. Often brands C10, C20 and HC35 are purchased for this purpose. They are available with a polymer coating and galvanized. In this case, the pitch of the lathing can be equal to 120-150 cm. Wall profiles are cheaper, the lower the value of the first number in the marking, the lower the price will be.

C10 sheets usually have a working width of 115 cm and a total width of 120. The length of a sheet can vary from 4 to 6.87 m. For C20 sheets the widths are 110 and 115 cm, respectively. They are distinguished by high strength, but the cost of a running meter will be slightly higher than that of products labeled C10. HC35 sheets have a meter working width, and the total value will be 106 cm. Their thickness varies from 0.4 to 1 mm, while sheets thinner than 0.6 mm for installation should not be purchased. The length of such products can reach 980 cm.

What to consider during installation

To find out how many sheets are needed for the fence, you need to divide its perimeter by the working width of one product. It is advisable to purchase products with a stock of several units. Before installation, it is necessary to prepare a drawing showing a diagram of the structure, dimensions of the fence, the main elements of its structure (including a gate and a wicket). Then the site is marked, the pits are prepared and the support pillars are mounted. Thick metal profile pipes can be used for their manufacture.

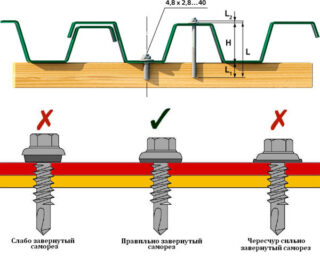

After pouring the pits with concrete, they are allowed to harden for a month. After that, the cross members are installed. For this, you can use brackets or a welding machine. Then metal sheets are attached to the lags using self-tapping screws.

It is best to carry out installation work in calm weather.