The bath is often built from a bar, and not from a log. It is not so easy to make a blockhouse: the logs need to be laid using a special technology. The building after erection gives a strong shrinkage. The beam is much easier to install and easier.

Varieties of timber

The beam for the bath is chosen carefully. Steam room, washing room, sauna - rooms that are exposed to extreme water and temperature changes. For such a complex, only a tree that is resistant to these factors is suitable.

Most often these are the following breeds:

- Oak is insensitive to water and steam, extremely strong and durable. However, this material is extremely expensive.

- Larch is the best ratio of durability and price. The tree is not prone to decay, does not dry out. The action of water only becomes harder and does not need constant care. Moreover, its cost is much lower than oak.

- Pine is a cheap option. Medium density wood, easy to process. The wood has few knots, is clean and beautiful. Pine is resistant to decay and mold due to the high content of resinous substances. You can build a sauna from pine, but you will have to decorate the interior from something else: linden, aspen, alder. In addition to pine, spruce, fir, and other conifers are also used.

- Cedar is resistant to water, steam, weather factors. When heated, it releases aromatic compounds that have a beneficial effect on the respiratory system. Expensive material.

In addition to the characteristics of the wood itself, other factors are also taken into account.

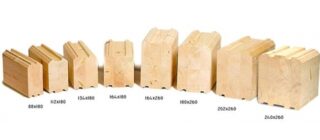

Section dimensions

What kind of timber for a bath and what size you need to buy depends on the size of the bath complex and the weather conditions in the region. A summer bathhouse, even in mid-latitudes, does not need additional insulation. For it, there are enough slats with a cross section of 100 * 100 mm, but if such a building is steamed in winter, it will be necessary to additionally insulate the complex or build from a thicker material.

The most popular solutions include:

- 100 * 150 mm - optimal for a summer building or for a bathhouse in the southern regions;

- 150 * 150 mm - suitable for all areas where the temperature in winter does not drop below -30 C;

- 200 * 200 mm - combines strength and thermal insulation properties.

The larger the cross-section, the higher the thermal insulation of the building the timber provides. But its cost also increases. In addition, the thicker the material, the heavier it is and the greater the load on the foundation.

Rectangular or square section

Which bar is better for a private bath - square or rectangular - is difficult to determine.

Rectangular, laid with the narrower side, forms a wall faster. That is, less such lumber is needed. However, the mechanical strength of the surface will be lower.

The square section is universal. So in the end, the choice comes down to the availability of material from the selected tree.

Features of using a bar in the construction of a bath

The types of timber for the construction of a bath are varied. Each option has its own pros and cons. What kind of timber is better to build your bathhouse from depends on a variety of factors, including the shape.

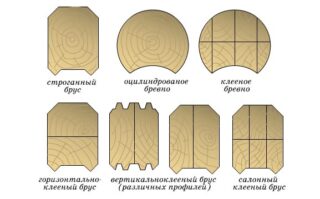

Unshaved timber

It is a log of natural moisture, which has been given a rectangular shape. It is convenient to install, since this configuration provides a tight fit of the elements and reduces the risk of cold bridges.

The main disadvantage is the high moisture content. Wood dries up already being a wall element. The beam shrinks, warps, cracks, the wall often deforms and loses its strength. The bath cannot be used after construction: it takes time for the tree to sit down. After shrinkage, the gaps that appear are additionally closed, and only then the bath is finished, windows and doors are installed.

Profiled timber

The material is expensive but more practical. It is made from dry wood and contains no more than 19% moisture. The material almost does not shrink and does not dry out. Secondly, grooves and protrusions are made on opposite sides of the elements. During installation, the elements are stacked on top of each other and connected. Such a building is much more durable. You can use the bath immediately after construction.

The downside is the rather high price.

Glued laminated timber

Made in an unusual way. The timber is obtained by splicing lamellas of different thickness and length. Since the fibers turn out to be oriented in different directions, this option does not lead to an increase in humidity, does not shrink, does not dry out and does not warp. The configuration of laminated veneer lumber does not change over time, even in the most severe climates.

In addition to its high cost, the material has another drawback. The tree is able to absorb excess moisture and bring it out. However, due to the manufacturing technology, the glued version of this property is deprived.

Comparison of materials

There are many materials that can be used to build a bath. You need to evaluate the merits and demerits of each option.

Beam or log

A log is a traditional material for a Russian bath. Such wood fully retains the advantages of the material: the highest heat saving, the ability to regulate the microclimate by removing moisture to the outside, exceptional durability and beauty.

However, the log shrinks a lot: the bath can be finished and glazed no earlier than 1 year after construction. And after that, she sits down a little every year. Stacking a log is very difficult. This requires high qualifications and experience. From time to time, the walls of the bath need to be caulked.

A log structure is inferior to a log house in terms of durability and comfort, but it is erected much faster. Many builders believe that it is easier to insulate a building from a bar than to fold it from a log.

Timber or brick

It is difficult to compare these materials as they have different properties. In general, brick and stone are not the best options for a bath, since brick is much heavier, has low vapor permeability and retains heat much worse.

But if a bath complex with guest rooms and a swimming pool is being built, brick may be the best solution.

Timber or blocks

Aerated concrete is the most budgetary option for construction. The blocks are much larger than ordinary bricks, the building is built much faster, the surface of most foam concrete is even, which allows the stone to join very tightly. Their thermal conductivity is much lower than that of ordinary concrete.

The disadvantage of cellular concrete is hygroscopicity. It is less for non-autoclaved foam concrete, for example, and more for aerated concrete blocks. Nevertheless, such walls must be carefully waterproofed, trimmed both inside and out. As a result, construction becomes more difficult, although it is cheaper than construction from laminated veneer lumber.

Beam or frame

From the point of view of thermal conductivity, the frame version, sheathed with heat-insulating sandwich panels, is the best option. In addition, the construction is very easy, it is assembled in just a couple of days. The sauna heats up quickly.

The main disadvantage is low vapor permeability.The steam room, washing room, dressing room will have to be equipped with artificial ventilation, which is not so cheap.

For a bath, you can take only sandwich panels with mineral wool as insulation.