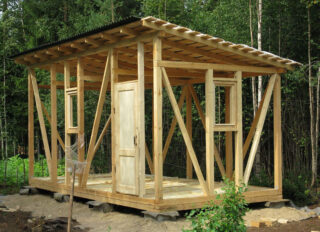

Temporary structures are erected on the basis of a wooden or steel frame. The parameters of the skeleton depend on the functionality of the room, materials of manufacture, the possibility of re-equipment for other purposes in the future. The frame of the change house is made strong, stable so that it can withstand not only the weight of the coating, the overlap, but also take the wind and snow load without deformation.

Professional and amateur buildings

A change house is an auxiliary structure that temporarily provides the general household needs of workers at a construction site, a summer residence. The room is used for short-term residence, storage of items, tools, materials.

Change houses for professional activities are erected taking into account the regulatory provisions of GOST 22.853 - 1986, GOST 25.957 - 1983, GOST 23.345 - 1984. For the internal arrangement, building SNiP standards are used.

The docs list:

- manufacturing specifications;

- definitions and terms;

- types of permissible structures, taking into account state standards.

Professional buildings range from mobile container buildings to prefabricated and sectional buildings up to two levels. Amateur buildings in private plots are built on a frame, sheathed with suitable material. Design decisions usually depend on the owner's budget.

Amateur frame-panel options differ from ready-made factory blocks in a short term of use and relative cheapness.

A frame shed in the courtyard of a housing under construction later turns into a bathhouse, equips itself for guests and servants. Its structure is chosen so as to painlessly carry out modernization after the end of construction.

Advantages and disadvantages of frame cabins

Owners often make wooden and metal skeletons for household buildings with their own hands, which leads to significant savings in wages for specialists. Frame houses are built using proven technology; standardized structures, elements and details are used for them.

Other advantages of timber and metal framing:

- the possibility of re-equipment and further use for residential or economic needs;

- the erection does not require lifting mechanisms, since the installation is carried out sequentially, each small-sized element rises after the installation of the previous one;

- just do the disassembly of walls, skeleton or dismantling;

- metal or wood is used for construction - environmentally friendly materials;

- the disassembled structure can be transported to another location.

The wooden or metal frame of the building change house has disadvantages. For example, a spatial solution of a certain type is limited by structural elements, so it will not be possible to significantly change its layout. You can only increase the dimensions of the building itself.

Wood absorbs water, from which it subsequently collapses and rots. Steel also corrodes when exposed to moisture. Both materials require pre-treatment prior to installation. After the assembly is completed, they are coated with paints or varnishes to extend their service life.

Types of cabins and frames

Country cabins are built from better materials, they pay attention to the appearance and internal arrangement. The owner can live in them for up to 15 years.

Change houses are:

- stationary;

- portable with dismantling;

- portable from factory block modules.

Stationary ones are placed as living quarters, which are used for living in a summer cottage in the summer. Sewerage and water supply are supplied to them, the premises are heated if necessary. For installation, they build a foundation, attach sheds, rest areas, such cabins can have 2 floors.

Projects for construction change houses are based on a frame made of materials:

- iron profiles;

- wood;

- combinations of metal frame and panel sheathing.

The structures can be moved, but for this you need to remove the sheets on the walls, dismantle the insulation, the roofing system. Therefore, modular schemes of ready-made factory blocks are used, which are towed by tractors, mounted using construction cranes.

Such products have openings, coverings, internal wiring of communications, ventilation. After installation, external collectors are connected to all outputs to provide the building with water, electricity, gas.

Modular cabins can be installed where there is a road for a tractor and a crane.

Construction of a frame made of metal and wood

Modern cabins are being built using new technologies, while the standards of the recent past are gradually disappearing. The buildings provide all the conveniences with air conditioning, ventilation system with recuperation and additional air purification. Inside there is a bathroom with a hot shower and a cooking area.

Frame construction is suitable for the implementation of such volumetric solutions:

- inside a large structure, the space is divided using frame elements, which are subsequently sewn up and play the role of walls;

- for the device of partitions between the functional sections of the change house, the creation of a foundation is not required;

- internal walls are erected quickly, since there is no need to lay walls made of small-sized bricks, blocks;

- insulation and sound insulation are performed during the construction process, and not on the surface of finished partitions.

The metal frame of the change house and the frame of wood are built using different technologies. The assembly method matters. For example, timber lumber is collected on bolts, pins, and joined using special samples in the body of the timber. The joints of steel structures are often welded, therefore they are classified as non-separable type. If the metal frame is also assembled on bolts, then such a structure can be easily disassembled.

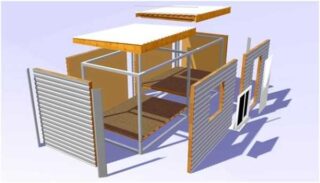

Prefabricated metal frame for the change house

Such models are produced at the factory, so there is a corresponding instruction and a drawing for the docking of individual nodes and connections for assembly.

There are points that are not noted in the manual, so you should pay attention to them:

- site preparation, leveling and removal of the fertile layer;

- installation of a foundation for the support posts of the building;

- after the installation of the frame, the hinge of the sandwich panels for the walls;

- arrangement of window and door openings, installation of frames;

- installation of a roof, roofing system.

Prefabricated reinforced concrete blocks are placed as a foundation, which are mounted under each rack or placed in the form of a strip base. The individual elements are connected with beams so that when the soil heaves they do not diverge to the sides.

It is allowed to concrete the supporting parts of the frame, each in its own pit. At the bottom, crushed stone is added, then the underground part of the rack is treated with molten bitumen 3 times, waiting for each layer to dry.

Welded metal frame for change houses

For such a structure, a mandatory drawing is required, since all the details must be cut off with your own hands. The quality of the building depends on the accuracy of cutting. Pay attention to the base of the frame, for which a professional pipe with a section of 40 x 60 mm is used.

Step by step guide:

- the pipe is cut, then the lower edging of the structure is welded in the form of a rectangle;

- you need two straps to put at the base of the frame and at the top;

- the same pipes are welded inside a rectangle for floor rigidity;

- they put racks in the form of supports at the corners of the change house (section 40 x 40) and on the line of the walls with a certain step (usually - 1 meter);

- the upper beam belt is welded;

- for a pitched roof, rafter girders are placed, supported by one end on larger racks than on the other side;

- the gable is welded from the trusses, the structures are assembled individually at a height or they are raised ready-made from the ground, if there is a crane.

During installation, a building level and a plumb line are used to coordinate the accuracy of the installation of the metal frame for the change house. Wall slabs of OSB, chipboard, sandwiches have right angles, therefore, discrepancies during installation will lead to size mismatches. The uprights are welded along the perimeter of the section to the bottom elements until they can stand upright without supports.

Stiffeners are welded between the racks, diagonal and angular struts are mounted. These elements will also serve as a support when hanging wall panels.

Recommendations for the assembly of modular rooms

Prefabricated modular containers are designed to be sturdy enough to be installed without a foundation. Their equipment is designed for different climatic regions. The products comply with sanitary, technical and fire safety requirements.

The assembly technology is determined taking into account the type of blocks used. There are modules that are delivered and installed ready-made. Alternatively, the individual parts are transported in packaging, then they are joined at the construction site. Panels in a collapsible model have built-in windows, doors, and other positions.

For connection, use special hooks, steel studs with nuts, bolts. Place corners at rectangular joints with holes on the plate and profile for correct fixation. For internal cladding, MDF, PVC panels, chipboards with moisture-repellent impregnation are used.