Materials for building a house are chosen based on the preferences of the owner and his financial capabilities, while taking into account the technical characteristics. Vertical fences must resist the transfer of heat, provide the required humidity and temperature conditions in the house.

The main qualities of the material for the house when choosing

Walls determine the durability of the house, their appearance speaks of the status of the owner, therefore, the choice of material is taken responsibly. Lightweight and porous stones do not require waterproofing, insulation, a profitable foundation is made for them, therefore, the cost of building a house is reduced. But for such walls, reinforcement with metal rods is used and a monolithic reinforced concrete belt is mounted before installing the floor.

When choosing building materials for walls, factors are taken into account:

- unit cost;

- heat insulating properties;

- labor costs for laying;

- the amount of funds for subsequent finishing;

- bearing capacity of the finished structure;

- fire hazard;

- moisture resistance;

- ecological cleanliness.

It takes more time to lay a brick wall than to build walls from gas or foam blocks. For large stones, the amount of mortar in the joints decreases. Appearance also plays a role. For example, ceramic or sand-lime bricks do not require external finishing, and shell rock, foam concrete have an unattractive appearance.

Stone walls are durable, but they do not protect well from the cold, therefore they require an insulation layer outside. The vertical elements of the house are fireproof, do not rot like wood, but the cost of the material is high. They use the technology of assembling a house from ready-made elements based on a metal or wooden frame.

House requirements for permanent residence

Continuous dwellings should be classified as permanent structures.

You can build a house for permanent residence with the following requirements:

- the building has communications in accordance with safety requirements, there is heating and ventilation;

- the house is located on a solid foundation, it has reliable vertical fences without cracks or damage;

- walls, roof, floor are insulated so that there is no mold, mildew on the surface, and the temperature in the room is + 18 °;

- natural lighting at the level of 0.5%, humidity does not exceed 80%;

- the minimum ceiling height in rooms is 2.4 m, and in attics or corridors - 2.1 m.

The area of the house and its overall height must comply with the urban planning standards adopted in the region. Technology and building materials are chosen so as not to repair structural elements every season. A cozy microclimate inside should be achieved without much effort and the use of complex life support systems.

The structure for permanent habitation serves for a long time, the service life exceeds 2 - 3 decades. The walls are insulated from noise and inside it should be at a level of 40 - 55 dBA during the day, 30 - 45 dBA at night. On the site, a residential building is located taking into account all the norms of indentation from outbuildings and neighboring houses.

Comparison of different materials

When choosing, building materials are compared according to certain characteristics, while taking into account moisture resistance, flammability, the possibility of releasing harmful components into the environment. They take into account durability, thermal conductivity, masonry speed, as well as load-bearing characteristics.

Comparative properties of some wall materials:

- The ceramic block belongs to reliable and durable materials with an average construction speed; it is used as a lightweight replacement for red brick. The stones are 380 mm thick, the material is fragile, water absorption is up to 15%.

- Aerated concrete is used for the construction of lightweight houses, while the walls do not require reinforcement, since the stones have the required density. The hygroscopic material allows water to pass through, therefore it requires a thorough waterproofing on the outside and a vapor barrier on the inside.

- Foam concrete is used to build a house for permanent residence without an insulation layer. The material has closed cells inside and is not saturated with moisture. It is necessary to do the reinforcement of weak points and the installation of a monolithic belt before laying the beams.

- Shell rock is of natural origin, therefore it is classified as environmentally friendly construction products. It is recommended for the construction of one-story houses due to its low strength.

The fire resistance of the walls should correspond to the norm of 60 minutes. This means that for such a time the wall must withstand open fire without reducing its bearing qualities. Such properties are inherent in bricks and foam concrete. The downside is that the metal frame loses its quality earlier than wooden structures, since in a fire the steel begins to soften and loses its strength.

Advantages and disadvantages of materials for building a house

Materials, the walls of which have served more than one generation of residents, have always been appreciated. This group includes ceramic blocks, bricks, stones. Modern options include foam concrete and aerated concrete, cement-bonded particle boards for cladding frame buildings. Earthen walls and adobe are a thing of the past long ago and are not used for the construction of walls, since the construction of such structures is distinguished by high labor costs, and buildings have more disadvantages than advantages.

Walls made of aerated concrete blocks protect the interior space well from cold, while a wall in one block has the same thermal insulation qualities as a thick wall (3 times wider) made of bricks. Aerated concrete does not deteriorate from time to time, since it belongs to materials with an unlimited service life. The blocks are distinguished by perfect geometry, so little glue or cement mortar is used in the masonry and there are almost no cold bridges. The disadvantage of aerated concrete is that during production, communicating internal cells are obtained and the material is saturated with moisture.

Brick

The walls will stand from 100 to 150 years, while external conditions or precipitation will not have a detrimental effect on the quality of the masonry. The technology of work is debugged to the smallest detail, because the material has been used since ancient times.

There are two types of building materials:

- ceramic red brick;

- white silicate.

The first type is produced by firing clay particles, so it is durable and does not harm health. Ceramic bricks are not afraid of temperature jumps and a humid climate. They produce solid (up to 13% of holes) and hollow (49% of voids) stones. The holes are made round, oval, rectangular or square in shape. With an increase in voidness, the thermal insulation properties increase.

The white silicate variety is produced from sand, lime with the addition of alkali-resistant or weather-resistant modifiers. Differs in high resistance to frost, surpasses lightweight concrete in this quality. It is dyed in different colors when manufactured using artificial pigments.

Both types of bricks are produced for the purpose of work:

- ordinary - building material for laying internal or external walls, which will be additionally decorated;

- front - facing elements of impeccable geometry and appearance without the slightest defects.

The disadvantages of bricks include the fact that the material has a significant weight and masonry requires labor and time. Massive walls are placed on a solid foundation for a large deepening. In areas with a cold climate, such houses require insulation.

Beams

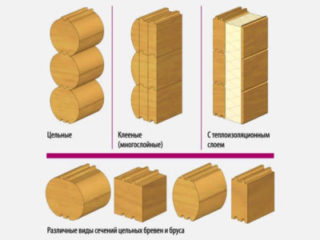

Types of timber for building a house:

- The sawn material has a moisture content of 50 - 70% and is used immediately after cutting. Undried timber shrinks during the first year of service by 7 - 10 cm, which leads to the appearance of cracks on the walls.

- Sliced timber is dried before use in an industrial environment, so the humidity is reduced to 20 - 25%. The lumber is cut off after drying, so the shrinkage of the structure is small.

- Glued laminated timber is made up of several layers of boards. Before that, they are dried to 6 - 10% moisture, combined under pressure. The resulting products are 7 - 30 cm thick, up to 12 m long. The walls made of laminated veneer lumber do not shrink over time.

The advantages of wood include a lower cost compared to brick. If factory logs are used, they are processed under production conditions. Profiled products have connecting grooves for a secure fit. Wooden houses are notable for their external beauty, so they are often not additionally finished.

Disadvantages are manifested in pre-treatment with fire retardants to protect against fire, antiseptics and other types of protection.

The shrinkage of a lumber house can last up to 3 to 4 years.

Foam concrete

Foam concrete is released from a solution of sand with cement. The mass is foamed, and it solidifies in this state. Air bubbles inside form closed pores that do not communicate with each other. Blocks are made by casting into molds or cut out from the solidified mass. Foam concrete is kept up to 28 days so that the material gets 100% strength.

A foaming agent of organic origin or synthetic production is introduced into the mass. Clay, binder fibers, ash can be added. Artificial foam formers are cheaper than organic ones, but produce low quality products. Protein blowing agents provide reliable quality and stronger baffles between pores.

Produce brands:

- D300 - D500 are used for thermal insulation, such stones are characterized by low strength, high protection from cold;

- construction of walls simultaneously with insulation - D500 - D900;

- structural version for the construction of load-bearing walls - D1000 - D1200, they have increased thermal energy conductivity.

They produce classic monoblocks in solid mass, produce hollow elements, and also produce innovative shapes in the form of Lego foam blocks with connecting side elements. There are foam blocks of 1, 2, 3 grades. The grade is taken into account if the outer surface of the wall is not planned to be finished; in other options, you can take the second grade.

The third grade of foam concrete is distinguished by many chips, irregular geometry, and the uniformity of the structure of the cells is disturbed. It is better not to use it to build a house for permanent residence.

Frame houses

You can build a house based on a steel or timber frame. The buildings are being built using accelerated assembly technology and save money on the purchase of building materials. The skeleton of the house consists of racks, struts, rafters, trusses, floor beams. The wall has a weight that is 5 - 10 times lower than a brick fence, because.the main filling between the bearing elements is their insulation.

Types of frame building:

- The frame-panel board is assembled from ready-made factory panels. They are connected to each other, then partitions are placed. The last step is to make the roof.

- Frame-frame type. A skeleton is assembled from logs, bars, which are installed on the foundation. The roof structure is made, then the gaps between the frame elements are filled with insulation with inner and outer sheathing.

The advantages of frame structures are that the walls do not allow the cold to pass through, and money is saved on heating. Internal additional finishing is not required, communications are carried out in the walls, which saves space. House remodeling is easy.

The disadvantages of frame houses include the low strength of the walls and a short service life compared to brick or block buildings. The facades are used standard, so the buildings are almost not distinguished by a variety of appearance. Inside, you need to do ventilation, since the insulation does not breathe and contributes to the creation of an uncomfortable microclimate.