Self-design of your own home is a complex process associated with the solution of many fundamental problems. The developer will have to decide what to make the floor of the house and what to use later as a finishing cladding. The choice is small - concrete or wood, but a lot depends on its feasibility: the microclimate in the premises, the strength and durability of the entire building, the need and frequency of major repairs. To approach this problem competently, you should familiarize yourself with the features, pros and cons of each technology.

Features of floors in a private house

In the overwhelming majority of cases, private developers, embarking on the construction of residential buildings, are experiencing an acute shortage of funds. At the same time, everyone wants their property to be beautiful, solid and comfortable. Independent construction can partially compensate for the financial shortage, since the services of hired workers are expensive. But in this situation, all responsibility falls on the owner of the land plot.

When designing, you should take into account the following nuances and features:

- With the ownership of the site, you can make the floor in the house from any material. Here, the owner does not have any restrictions that are regulated for apartments in multi-storey buildings. Both the floor and its finish can be of any weight, thickness and composition.

- If multi-storey buildings stand on a solid strip foundation, where there is a sealed and warm basement at the zero level, then under a private house there is land subject to heating, freezing, filling with ground and melt water, drying out and heaving. This means that the issues of thermal and waterproofing are as important as the performance of the structure.

- When deciding which floors are best done in a private house, wood or concrete, you need to focus on the advantages and disadvantages of each material. If you can save money in one place, then you will definitely have to invest in another.

To make the best decision, you need to compare the characteristic properties of each material.

Floor options

In private construction, the choice is based on several factors. Fundamental are the type of foundation, the type of soil and the expected load inside the premises.

There are floor options that differ in composition and manufacturing technology.

Concrete

Reinforced slabs have the following advantages:

- high compressive and tensile strength;

- complete waterproofness;

- mold and mildew resistance;

- long, practically unlimited service life;

- smooth outer surface, ready for finishing;

- the possibility of using it as a finishing floor after polishing.

Cons of this design:

- heavy weight requiring a strong foundation;

- high thermal conductivity, which is why thermal insulation is always required;

- the need for a long wait for the composition of full strength to be picked up;

- labor intensity, the need to apply great efforts during construction.

Hollow core slabs with low weight and good insulating properties can be the optimal solution.

Wooden

It is a traditional technology with centuries of successful application in a wide variety of conditions. The structures consist of timber, boards, layers of vapor barrier and insulation. Lags can be installed on a screw, strip and slab foundation.

Advantages of a wooden floor:

- ecological cleanliness;

- tactile warmth even at low temperatures;

- presentable appearance;

- excellent thermal insulation characteristics;

- the ability to regulate the level of humidity in the room;

- the possibility of self-assembly without the involvement of construction equipment;

- variability of finishing cladding;

- maintainability.

Disadvantages of the design:

- high requirements for moisture protection;

- reduction in useful volume due to stacking high lags;

- susceptibility to decay, mold and insect infestation;

- limited service life;

- tendency to dry out, deformation, the appearance of knocks and squeaks.

In private construction, underfloor heating technology can be used without restrictions. In concrete, cable, matt and water systems can be installed. In wood, given their insulating properties, it is only infrared.

Selection rules

The floor for a private house is a structure that is often hidden under the outer cladding, but nevertheless it has a rather large impact on the living conditions in the house.

The following gender selection criteria should be adhered to:

- strength;

- environmental Safety;

- soundproofing;

- resistance to dampness;

- absorption of noise;

- maintainability;

- durability;

- constancy of form;

- immunity to mold and mildew;

- the ability to do it yourself;

- applicability to a wide range of exterior finishes.

Particular attention to the quality of the overlap is given to living rooms, where people often move and stay for a long time. The requirements for the coverings of auxiliary premises are not so strict, there you can only dwell on strength, reliability and safety.

Required tools and materials

Arrangement of concrete and wood floors involves the use of different sets of tools and materials.

For the manufacture of concrete products you will need:

- concrete mixer;

- Bulgarian;

- level;

- rule;

- roulette;

- Crochet hook;

- putty knife.

List of materials:

- composition for concrete (sand, cement, crushed stone);

- fittings;

- knitting wire;

- primer.

To make wooden flooring, you need the following tools:

- hacksaw;

- a hammer;

- screwdriver;

- drill;

- plane;

- paint brush.

In all cases, protective goggles and gloves must be worn.

Step by step guide

The installation technology of each material is fundamentally different, both in the ways of implementation and in terms.

The concrete slab should be done in the following sequence:

- Manufacturing of formwork on the ground or boards on supports.

- Laying waterproofing.

- Installation of the reinforcement cage.

- Preparation and pouring of concrete.

- Leveling the surface.

- Holding the screed up to 28 days to gain strength.

- Final leveling and priming of the slab.

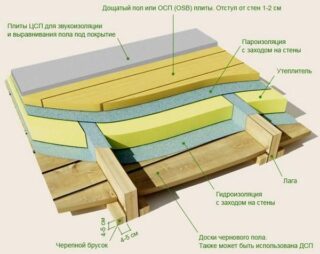

Wooden floor manufacturing method:

- Laying waterproofing on supports.

- Cutting log blanks, wood processing with antiseptic, fire retardant and hydrophobic impregnation.

- Laying and securing beams.

- Installation of the subfloor.

- Installation of waterproofing.

- Placement of insulation for honey with lags.

- Installation of the second layer of waterproofing.

- Installation of finishing coating. Carrying out its comprehensive processing.

In all cases, partitions should be provided in the middle of the floors. Both structures are prone to sagging, the partitions will be able to resist this.

Topcoat materials

The following materials are most popular:

- Tile and stone. The strongest and most durable option, resistant to moisture, chemicals and abrasion.

- Linoleum. High-quality models are characterized by increased reliability and durability. Can be laid directly on concrete or pre-leveled boardwalk.

- Laminate. The panels are assembled into a monolithic shield, they look beautiful and presentable, but a perfectly flat plane is required for installation.

- Carpet. The soft roll coating is pleasant to the touch and has excellent insulating properties. It is advisable to lay in places with low traffic.

In all cases, the choice of coverage is advisable if the location of its placement is correctly selected and the installation rules are followed.