Wood heating is popular among summer residents and owners of private houses. Effective heat transfer allows you to warm up the house, so there is no need to purchase expensive gas equipment. The owner chooses the best wood-burning stove for home heating, taking into account the power, appearance, material of manufacture. The cost of installing a hearth pays off quickly.

- Benefits of heating with wood

- Features of wood stoves

- Varieties of ovens

- Stove-potbelly stove

- Cast iron units

- Pyrolysis units

- Fireplace types of hearths

- Furnaces for the water circuit

- Ovens with hob

- Long burning oven

- Choosing a wood-burning hearth for your home

- By power

- By type of fuel

- By furnace material

- By design

- Homemade devices

- By functionality

Benefits of heating with wood

The quality of firewood is directly proportional to the heat emission coefficient and the density of the wood. As a result, the specific heat of combustion and heating efficiency are increased.

In stand-alone systems, wood-fired boilers occupy high positions due to the advantages:

- ease of maintenance;

- ecological cleanliness;

- economical work;

- long time of operation.

Wood stoves are placed in any room from the garage to the fireplace room. You can make such a stove for a country house with your own hands.

Features of wood stoves

Wood-fired heating units show efficiency at the level of 85 - 90% during operation. This means that the stove heats up the room, the water circuit with almost no heat loss. The disadvantage of such installations is the long heating time.

Modern heaters combine several functions:

- cooking and baking food;

- drying, provision with hot water;

- connection of the circuit with radiators.

There are units that can simultaneously operate in the mode of a fireplace and a long-burning heater. Other versatile models have a built-in generator to convert heat into electricity.

Varieties of ovens

Wood-burning heating devices are presented in a large number of models. In the rating of modern stoves and fireplaces, there are options for which brick, steel, cast iron serves as the material.

All types of stoves have standard components:

- firebox;

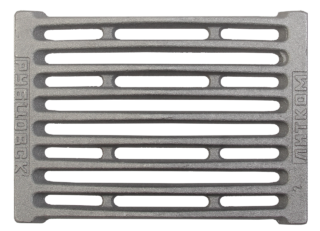

- grates;

- blew;

- chimney.

In houses, for heating on wood, cast-iron boilers, pyrolysis units, fireplaces, Kuznetsov's long-burning stoves, and potbelly stoves are used. Hobs, water circuits, hot water tanks, ovens are built into the structure.

Stove-potbelly stove

It is a kind of inertialess stove - it starts heating the room immediately after kindling, but also cools down quickly after it burns out. It is relevant for temporary premises, for example, workshops, garages, change houses.

Features of burzhuikas:

- the body, the chimney of the furnace are made of iron;

- are distinguished by an increased fire hazard;

- can be easily made by yourself.

The shops have a selection of modern models with a beautiful appearance. The stove surface is covered with persistent colored enamels, glass doors made of heat-resistant glass are installed.

Cast iron units

They have been used in residential buildings since the beginning of the 19th century; units have undergone many modifications and improvements during this period.

Cast iron stoves are characterized by indicators:

- high heat dissipation;

- durability of work up to 35 years with proper maintenance;

- long heat retention;

- corrosion resistance, durability.

The disadvantages of cast iron include fragility and high weight. Modern cast iron units are included in the top 10 budget stoves for summer cottages, since they are easily transported disassembled. It is easy to install them for a person without qualifications.

Pyrolysis units

It is based on the principle of thermal decomposition of wood (combustion) with the release of gases that are generated with a lack of oxygen. After the air is supplied, the gases quickly burn out and generate additional heat.

The advantage of pyrolysis units:

- two-chamber combustion of substances allows you to fully benefit from firewood;

- the amount of fuel used is reduced.

Uniform heating of the room is ensured, a constant temperature is maintained.

Fireplace types of hearths

The open hearth fireplace is popular for its ease of use, heat-up speed and a particularly cozy atmosphere. The chimney sends combustion products outside the premises, providing the necessary draft.

Models developed:

- built into the wall;

- attached views.

There are fireplaces with open, closed and half-open combustion chambers. Open fireplaces show low efficiency (at the level of 30%), closed fireplaces increase this indicator up to 50%.

Furnaces for the water circuit

A metal heat exchanger is built into a wood-fired unit, which supplies a liquid coolant to a system of pipes and radiators to heat other rooms in the house.

For such a distribution, structures of various types are used:

- brick simple and long burning;

- metal and cast iron machines;

- pyrolysis boilers.

The circulation of the energy carrier is carried out in a natural or forced way with the help of electricity. Despite the complexity of installation, such ovens operate and maintain simply.

Ovens with hob

Wood-burning stoves for heating a summer cottage with a stove solve the issue of heating at the same time as cooking. Often a built-in oven is added to the hob, located above the firebox through special brick gaskets.

Models provide devices for convenience:

- department for drying products;

- a chamber for maintaining the temperature of food;

- compartment for warming up plates before serving.

Modern designs are produced in a complex design. For example, one oven runs on wood, the second on electricity, and gas burners are provided for cooking from above.

Long burning oven

The peculiarity of the Kuznetsov bell-type furnace is that the smoke circulates not only through the channels inside the structure. It enters special compartments, where it lingers, and additionally heats the brick structure. After cooling, the gases are directed into the chimney and discharged outside.

The thrust is obtained due to the internal void under the hood, so less bricks are used for construction. There is a possibility of combining with a DHW and hot water heating circuit. Minus of the furnace in complex masonry, which can be performed by a specialist.

Choosing a wood-burning hearth for your home

Massive stoves require foundation laying, therefore this fact is taken into account when determining the type of heating unit. In some houses, for example, with a basement, it is problematic to install such a structure.

The efficiency depends on the chimney. Consider the possibility of installing removable pipes or connecting to built-in ducts inside the walls. Fireplaces take away part of the room, therefore, they consider built-in models with two fireboxes in adjacent rooms, install corner or suspended options.

By power

A source of too much force causes the same number of problems compared to an under-powered unit.Reducing the burning rate to reduce heat transfer leads to increased soot formation.

Recommended power parameters:

- housing area 30 m2 will require a boiler power of 4 kW;

- 50 m² - 6.5 kW;

- 80 m² - 10 kW;

- 100 m² - 12 kW;

- 200 m² - 25 kW.

When choosing a stove for a summer residence, take into account the functionality of the hearth, the presence of additional heat sources, the degree of thermal insulation of the walls, roof and floor of the house.

By type of fuel

Models are in demand that can run on wood, but provide for the possibility of switching to liquid or gaseous fuels.

In addition to firewood, they use:

- coal, charcoal and brown coal;

- pellets, briquettes from coal, peat, wood;

- peat;

- liquid fuel;

- gas.

Liquid types include fuel oil, diesel fuel, kerosene, and automotive waste oil. These types are used where firewood is expensive and not available to all users. Gas can be natural or artificial, obtained from oil refining.

By furnace material

Brick, iron, cast iron have different properties, most of all, when choosing, they take into account the thermal expansion of the material, fire resistance. The individual elements of the furnace are heated to different temperatures, therefore they increase in volume unequally.

The durability of the hearth walls plays a role. For metal models, the parameter depends on the thickness of the steel, therefore 4 - 6 mm is chosen. Refractory ceramic bricks are used. Fireclay bricks are used for laying the combustion chamber.

By design

An impressive unit should have a beautiful appearance, since it takes up a lot of space in the room, they immediately pay attention to the stove.

For external design, you can choose the finish:

- tiles with interesting relief;

- majolica with patterns and glaze;

- clinker tiles;

- natural and artificial stone.

The simplest finishing option provides for whitewashed clay plaster. There is an option for painting the leveled surface with fire-resistant color compounds.

Homemade devices

A stove from Afanasy is used for heating, which is known under the name "bubafonya". It is made from a two-hundred-liter barrel or slightly less.

The Gnome model is assembled from sheet steel 4 - 5 mm, or a solid-drawn iron pipe is used. Better to take without a seam, but with a joint is also suitable.

A potbelly stove can be made from a barrel, it is combined with a brick base and an iron chimney.

There are options for making a homemade buleryan, which provides for a system of convection passages from pipes and a scheme for additional combustion of gases.

By functionality

The versatility of the wood-burning stove allows you to choose options with a built-in open fireplace insert. There are options for placing a couch on the stove for rest or sleep.

They choose small ovens only for cooking products or use multifunctional units. An outer tubular or ribbed casing is built into the oven to increase convection and the rate of heating the room.