High demands are placed on the garage floor. It bears the load from the car, the surface should not deteriorate under the influence of gasoline, fuels and lubricants, heavy tools and equipment. The floor of the garage can be wood or polymer, but most often a concrete screed is used, which has high strength and durability. You can fill the floor surface with concrete yourself. The coating does not burn, does not emit harmful substances, is not afraid of the effects of chemicals. However, the concrete floor has a porous structure due to the properties of the components from which the mortar is prepared.

Why paint a concrete floor in a garage

As the concrete dries, small pores appear on its surface and microscopic cracks appear, which subsequently cause erosion of the surface layer of the screed and the appearance of cement dust. Coloring the floor will help get rid of this problem.

Wear-resistant paint will increase the life of the concrete screed because:

- additionally protects the surface from moisture and chemicals;

- prevents the destruction of the surface layer of the concrete screed and the formation of cement dust;

- reduces the time for cleaning the garage.

To get the positive effect of painting the floor in the garage, you need to ensure that the concrete screed meets the requirements for the arrangement of garages. You need to use paints that are designed to perform such work.

Types of paint

There are different types of paints for painting concrete:

- based on alkyd, acrylic or epoxy resin;

- polyurethane paints and mastics;

- liquid glass;

- rubber paints.

Some types of materials are self-leveling coatings that create a durable protective layer on the floor surface.

To improve the quality of the flooring, special primers for concrete are used. They are made on the basis of epoxy or polyurethane resins. Suitable for all types of paints used for painting concrete floors.

Rubber

Ideal for garage flooring as they are non-toxic. Thanks to their constituent rubbers, they provide:

- creation on the painted surface of a strong and at the same time elastic film that can withstand high loads;

- high level of fire safety;

- the ability to paint the floor even at low temperatures.

The disadvantages of rubber paints are the high consumption of material at a fairly high price.

Alkyd and acrylic

They are considered modern substitutes for oil paints because they have a similar curing process.

- Acrylic are based on polyacrylic polymers.

- Alkyd resins are made from alkyd resins obtained by heat treatment of vegetable oils.

Both materials are universal and are used for painting the floor in garages.

Alkyd paints form a harder but less elastic film than their oil-based counterparts. They are used to obtain a shiny, but at the same time durable surface with a rich color. Among the shortcomings, the main one is insufficient resistance to ultraviolet radiation during intensive use.

Acrylic paints are less bright, but retain their strength and aesthetic characteristics at high temperatures. The disadvantage is the high cost.

Polyurethane

Polyurethane compounds are divided into two types - mastics and paints. Both options are suitable for painting concrete floors. They are characterized by high performance characteristics, including durability and wear resistance. There are two- and one-component compositions. Unlike the latter, the former, before starting work, require mixing their constituent components according to the attached instructions.

Polyurethane mastics have a thick consistency, which allows them to be applied in a thick layer, while masking minor damage to the floor. Also, with the help of mastic, the floor is waterproofed, at the same time strengthening the surface of the concrete screed.

Polyurethane mastic can be tinted.

Unlike mastics, polyurethane paints have a more liquid consistency, which is why they are applied in a thin layer, no more than 1 mm. In this case, careful preparation of the floor surface is required, since a thin coating layer is not able to hide existing defects.

Epoxy

All epoxies are two-component, mix immediately before application to the floor. Their characteristic feature is their high strength, which allows them to withstand atmospheric and mechanical influences. Therefore, epoxies are often used as a coating for the area in front of the garage.

The disadvantage of epoxy coatings is that the finished compositions lose their properties very quickly. Therefore, they need to be applied in an accelerated way, which requires certain skills.

Liquid glass

Silicate-based paint has a thick consistency, which is why it is quite difficult to apply it to concrete.

To facilitate the painting process, liquid glass can be diluted with water, but only in the proportions recommended by the manufacturer.

Silicate-based paints have high elasticity, which does not prevent them from hardening the floor surface. In addition, liquid glass reliably protects the concrete screed from moisture penetration.

Material selection

When choosing a wear-resistant concrete paint for a garage floor, you need to consider the following factors:

- the degree of surface load, which depends on the type of vehicle and the equipment installed;

- the likelihood of aggressive substances on the floor;

- the possibility of falling heavy and sharp objects;

- exposure to high temperatures during welding;

- the slope of the floor in the garage and its direction.

When choosing a material, the humidity in the garage in the winter season is of great importance. Also, the choice largely depends on the method of applying paint: with a roller, brush, spray gun or in bulk. Given the large floor area, concrete paint in a garage should be suitable for use with a pneumatic spray gun.

In dim lighting conditions, the color of the paint is of no small importance. Experts recommend using materials of light, pastel colors that add light.

General rules for painting a concrete floor

The process of painting a concrete screed in a garage includes a number of mandatory steps:

- Surface preparation - sealing existing cracks and potholes with a special primer.

- Dust removal.

- Depending on the type of material chosen, maintaining the manufacturer's recommended parameters of humidity and temperature during the process of painting the floor.

- Priming the surface if necessary.

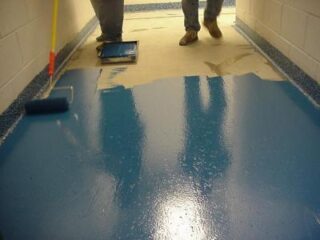

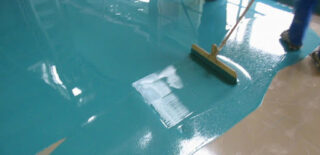

- Application of the first coat of paint - the thickness and method of application must be in accordance with the instructions given in the instructions for use.

- Application of a second coat, if necessary, after the first coat is completely dry.

- Providing conditions (temperature, humidity, holding time) required for complete drying of the coating.

When painting the floor, you must adhere to safety rules and ensure proper ventilation of the garage. The presence of overalls and a respirator will not hurt.