Lining is one of the most common materials used to decorate the interior walls of wooden rooms. It is made up of thin boards of the same width. The name of the material is due to the fact that in the past it was used for the inner lining of the walls of railway cars. The impregnation for the lining inside the house will help to increase the service life and prevent damage by fungus and mold. Such formulations prevent wood degradation caused by moisture.

The goals of protecting the lining inside the house during processing

Sometimes tenants doubt the need to process the lining inside the house. If the boards are not impregnated, they will change color as they are used. In case of insufficient ventilation, the coating becomes bluish. This is due to the work of microorganisms, which can only be removed with strong chemical oxidants. This procedure is quite difficult to carry out.

Planks can become grayish on exposure to sunlight. You can remove it by grinding, but after a while it will reappear. To prevent such problems, the lining is covered with a protective compound.

If the boards are treated with a water-repellent compound, they will last a long time even in a room with increased dampness, not subject to regular heating.

Variety of materials for processing lining

On sale there is a large selection of compositions with which you can process the lining inside the house in the country. Their main purpose is to reduce the flammability of wood, to protect against microbes and dampness. Some residents prefer to preserve the original appearance of the material and believe that it is enough to treat the boards with antiseptics.

You can choose a mixture that will have not only protective but also decorative properties. Sometimes painting the lining is practiced.

Primer

Usually it is not used as an independent composition and serves as a basis for paints and varnishes. The application of a primer promotes better fixation of the decorative coating, protects the wood from swelling. You can use a spray gun to saturate the boards. It is better to handle the joint areas with a brush. Acrylic and alkyd primers are well suited for lining.

Aqualaki

Wood varnishes are one of the most common categories of compounds that can be used to process lining inside the house. For such purposes, it is recommended to choose water-based varnishes. They are significantly less allergenic than mixtures based on organic liquids, although they take longer to dry. They also form a vapor barrier to prevent contamination of the open pores.

A wall covered with scuba can be completely matte, slightly shiny or glossy. When added to the color scheme, a coloring mixture is obtained. It works well to protect the wood from the inside, but you should not use it for exterior decoration: the paint is quickly washed off under the influence of environmental factors.

There are different options for scuba diving, containing additives that form certain specific properties. Modifications with antimicrobial components help to increase the life of the wood.If the coating is exposed to sunlight for a long time, it is worth buying a composition that minimizes the effect of ultraviolet radiation on the appearance of the lining.

The most resistant lacquer products are alkyd. Such a coating retains its fresh appearance for about ten years. In a wooden dacha or residential building, they are recommended to cover the floor. For walls, it is suitable if the owners prefer constancy in the interior. If, nevertheless, there is a desire to change the color of the walls, another one can be applied over the alkyd varnish.

Oils

Since ancient times, drying oil obtained from oils has been used to work with lining. However, this composition has disadvantages - it makes the wood sticky and changes its color. Today, there are also more technologically advanced oil-based products on the market that are well absorbed by wood. This mixture must be gently rubbed into the surface. Then the wood is polished. Depending on the ingredients in the mixture, the surface may appear matte or shiny.

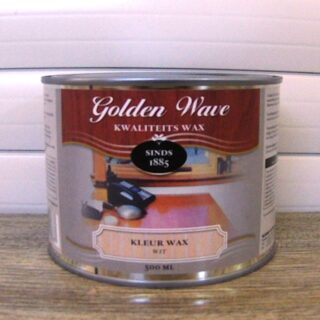

Waxes have a chemical structure similar to oils. They are very resistant and able to stay on a tree for several decades (if there is no significant mechanical stress). The surface is smooth and shiny. Before applying hard wax to the wood, it is melted in a water bath. You can also purchase a ready-to-use composition. For even distribution, a primer is pre-applied to the tree.

Required tools and materials

In addition to the impregnating composition itself, you need to prepare the application toolkit. This can be a spray gun or a set of brushes of different sizes. The product packaging contains detailed instructions for the application process, which indicates the recommended tools.

Also useful for work:

- construction tape;

- absorbent wipes;

- container for a coloring product;

- sandpaper No. 240.

It is better to prepare a separate small brush for smearing the joint areas. To prevent fluff from sticking to the surface, tools should be periodically rinsed in soapy water. It is worth doing this before starting to apply the product.

Preparatory work

Before impregnation, you need to assess the condition of the boards. If they have dark spots, they are removed with a special bleach. The surface is wiped with a solution of soda (0.3 kg per 10 liters of water). This procedure is done before the impregnation of the fresh lining, as well as if the boards were previously varnished and the coating is still in good condition. When the surface is completely dry, it can be primed and painted according to the instructions.

If the paintwork has lost its presentable appearance, begins to crack and flake off, the previous layer must be removed. This can be done in different ways. If you plan to make the new coating transparent, the mechanical method will do. For this, the surface is warmed up with a construction hairdryer. When the coating begins to peel off, remove it with a spatula. To remove oil paint, such a modification of the method is also used: foil is laid on the boards, and ironed on top with a heated iron. The separating composition is collected with a spatula.

If the lining will be painted, you can use special removers to remove the old coating. This is a rather aggressive method, moreover, the products can whiten the surface unevenly. If the owners plan to apply a colorless coating, it is better not to risk it and remove the old paint by heating. After using a chemical remover, the surface is well washed with water. If there are metal inserts on the surface, wipe them with vinegar.

Do-it-yourself lining processing inside the house

The temperature in the room where the treatment takes place should be above +15 degrees.

Before applying, the impregnation must be stirred so that the composition lies on the surface evenly. If a brush is used, the product is applied with the bristle tips.Do not press the tool to the surface.

For hard-to-reach areas (area near batteries, baseboards, etc.), use a thin brush (maximum 50 mm wide).

It is better to start staining from above. To make the coating durable, it is applied in several thin layers. In this case, each subsequent one is created only after the previous one has dried.