A wicket is placed in the fence of a private property. A widespread design is a wicket made of a profile pipe. The filling of the canvas is chosen in combination with the material of the fence, gate, and the dimensions should allow a person of different builds to pass freely and carry a handcart. One-sided or pendulum hinges are used, the handle is placed at the height of a bent arm for convenient opening.

- Pros and cons of gates from professional pipes

- Building structure

- Swing or sliding

- Selection of material

- Characteristics of a professional pipe

- Drawing and preparation

- Dimensions and shape

- Necessary tools for work

- How to weld a gate correctly

- Installation of pillars

- Frame fabrication

- Hanging on poles

- Installation of hinges

- Sheathing and decor

- Painting the product

- Locks for wickets

Pros and cons of gates from professional pipes

The design has positive and negative characteristics. The simple manufacture of the frame and the canvas itself, convenient installation lead to the fact that you can make a gate from a profile with your own hands. The pillars are dug into the soil by performing a simple preparation of the bottom of the pit.

Design advantages:

- long service life;

- low cost of building materials;

- beautiful view;

- corrosion resistance subject to cutting and welding technology.

Thin-walled shaped pipes are not strong against mechanical stress and impacts. The steel frame contributes to the propagation of sound, and the slightest damage to the protective coating causes destruction of the metal.

Building structure

The wicket consists of supports in the form of pillars and a door leaf on a frame, which is fixed to the posts using awnings. For closing, locks and locks are cut in. The pillars are made of bricks, made of steel, reinforced concrete or wood. Embedded parts made of thick metal, a corner or a rod are inserted inside the monolithic and stone supports in order to weld the wicket frame from the professional pipe to them.

The door is made in the form of a separate passage in the fence or combined with the gate. In this case, the wicket frame is placed in one of the leaves. If there is a sidewalk in front of the yard, the opening is done inward so as not to interfere with pedestrians. In this case, the size of the canvas is taken into account so that there is a distance for the complete opening of the sash.

Swing or sliding

The first option is referred to as inexpensive structures that are easier to cook and install. Such a wicket does not require a base device for the installation of guide beams, it does not need a counterweight and roller elements. The swing system is combined with the gate and saves space in front of the entrance. At the bottom, the canvas is cut in height in areas with heavy snowfalls. So the opening is not affected by the formed snowdrift.

Sliding schemes are more complicated, since guide runs are often placed at the bottom, they require an even foundation. There are options with a cantilever movement of the canvas, in which the beam is hung so that it does not limit the height of the span, and the rollers are placed inside the sash frame. Automation is installed on swing and sliding systems.

Selection of material

The inner filling is made of mesh, artistic forging, such a structure looks delicate, revealing a view of the inner space of the courtyard.Profiled sheeting is used more often because of the rich choice of colors and patterns for stone and wood.

For the canvas, cellular or monolithic polycarbonate is used, sandwich panels are installed. Sometimes forged elements are combined with wood filling.

Characteristics of a professional pipe

Profile pipes are called pipes, the cross-section of which differs from the round one, for example, it is oval, rectangular, square. For wickets, the last two types are used. The raw material is low-carbon steel (09G2S or St3Sp). There are options for a stainless steel pipe.

Material characteristics:

- strength and durability;

- low cost;

- small mass.

Products are produced by cold and hot pressing of longitudinal electric-welded round pipe. After that, the products are subjected to control and heat treatment to eliminate internal stresses. A pipe is produced with a cross section from 10x10 mm to 500x500 mm, the walls are made with a thickness of 1 - 22 mm. Sections 6 - 18 m long are on sale.

Drawing and preparation

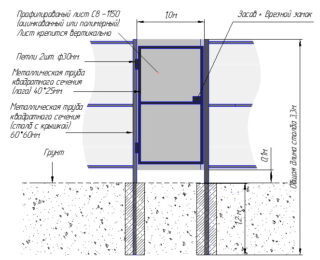

At the initial stage, they think over the design, select materials and make a sketch of the future product. The drawing shows the arrangement of the racks in plan and makes a schematic representation of the appearance.

Information contained in the sketch and its description:

- the dimensions of the supports, the material of manufacture;

- the depth of installation in the soil, taking into account freezing and standing groundwater;

- section of a professional pipe for welding the frame of the frame, dimensions of the canvas;

- enlarged nodes for joining elements;

- a description of the opening method and the necessary fittings.

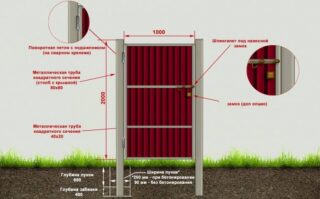

The optimal solution would be a wicket made of a 40 x 20 mm profile pipe, but the exact section of the profile is taken taking into account the load from the filling and the width of the span.

Dimensions and shape

The height of the wicket is made according to the size of the fence, sometimes it is reduced by 15 - 20 cm. The width is taken in the range of 0.9 - 1.2 m. The large size of the wicket will make the structure heavier and require powerful hinges.

Diagonal struts are inserted inside the frame to increase rigidity and resistance to deformation. Additional details increase the weight, which is taken into account when choosing the section and material of the pillars. Diagonals are placed from the center to the corners of the canvas and vice versa. Such schemes are beautiful. In another case, the amplifiers are placed between opposite corners or small diagonals are made at the corners of the frame.

Necessary tools for work

For excavation, use a bayonet shovel, scrap. They transfer sand, crushed stone, cement with a stretcher or buckets, knead in a concrete mixer. A small volume of the mixture can be prepared by hand in a trough, mix with shovels. To weld a wicket from a profile, welding is needed, consumables are bought for it.

Other tools:

- rammer for gravel, sand, electric vibrator for concrete;

- grinder with a grinding and cutting wheel for metal;

- electric screwdriver and drill;

- level, square, plumb line, tape measure 5 m, core.

An angle grinder (grinder) cut off the details of the frame and diagonals, using a grinding wheel, they clean the welded seams from scale. In different cases, other tools may be required, such as an ax, to cut roots in the ground.

How to weld a gate correctly

The location of the passage in the fence is chosen, taking into account a convenient approach to the building, flat terrain without a slope. A foundation is made for sliding gates:

- remove the fertile layer from the surface of the earth by 15 - 20 cm;

- dig a trench to a width and depth of 0.5 m, the length of the base will be equal to half the length of the sash (for a canvas of 1 m, you need to dig a trench of 0.5 m);

- make two indentations for the installation of pillars to a depth of 1.3 - 1.5 m, and the width is used 2.5 times the section of the rack or pillar;

- perform sand and crushed stone bedding, ram;

- welded fittings, laid on the bottom of the foundation.

The foundation is concreted at a time so as not to make joints.

Installation of pillars

The supports are placed so that they are slightly higher in height than the wicket leaf, and the sash is 5-10 cm higher than the ground level.The sash can loosen the pillar over time, so it is buried at a depth of at least 1 m, while the lower end is deepened into the pillow from rubble.

On the underground part, metal rods are welded crosswise for stability, which are then concreted. The frame is hung only after a week, when the concrete has completely hardened and gains strength.

Frame fabrication

To make a gate from a metal profile, you need to weld a frame from a pipe. Before cutting the parts, the surface is degreased and cleaned with special preparations. Apply an anti-corrosion agent. The pipe in the corners is cut at 45 °, and the T-joints are joined at 90 °.

Measure the width of the product between the posts in place.

Step-by-step instruction:

- cut off the crossbars and racks (2 pieces each);

- the crossbeams are tacked by spot welding to the embedded parts, taking into account the horizontal position;

- racks are welded to them with a continuous seam;

- they control verticality, right angles, put awnings.

The open ends of the pipes are sealed with sealant, welded or plugs are made so that moisture does not get into the holes.

Hanging on poles

To fasten the frame frame, embedded elements are concreted in the posts. In the brick supports, the brick is carefully trimmed so that the plate sits down. At least two of them are placed on one span. On metal racks, the hinges are fixed to the posts using vertical tires from the canopy installation corner. You need to weld with a continuous seam, leading it along the junction.

There is an opinion that the hinges can be fixed directly to the embedded elements. But such parts will not be able to withstand the dynamic loads from the movement of the sash for a long time. Therefore, they put a vertical bus. The element is additionally buried in the ground if the weight of the wicket door leaf is large. In addition, a channel is welded along the bottom to the width from one pillar to another.

Installation of hinges

Mounting the hinges on the pole bus is a crucial moment, which is given attention. The lower canopy is installed first, while doing a repeated check of the horizontal and vertical level and recheck with a plumb line. It is preliminarily tacked by welding, and after alignment, it is welded with a continuous seam.

The second is mounted on the upper hinge, while observing the vertical axis of the installation. Actions are no different - they control horizontal and vertical. After the final alignment, the attachment points of the horizontal crossbars are beaten off. The wicket should open in the opening without delay.

Sheathing and decor

Wood filling is popular as the material belongs to the category of environmentally friendly sutures. The wood burns, is destroyed by microorganisms, absorbs moisture, therefore, the sheathing requires processing before installation.

It is easy to install profiled corrugated board; anti-corrosion protection is already present on its surface. The material is lightweight with a wide choice of surface types.

Forging is an artistic variety of metal trim parts. It is a durable ornamental ligature that can be combined with many finishes.

Polycarbonate is available in transparent and color-tinted. The material allows you to view the interior spaces of the courtyard in blurred outlines.

Painting the product

It is impossible to simply paint the details of the wicket, since the coating will fade over time or begin to peel off in layers. Changes in appearance cause corrosion under the topcoat.

Sequential steps in the finishing process:

- cleaning the coating using a grinder with a circle;

- if there are traces of the paint system on the structural metal (used pipe), it is removed with special washes;

- treatment with anti-rust preparations;

- cleaning with emery, degreasing with acetone solvents.

The protruding white plaque is removed with rags or sponges. After that, a primer layer is applied to the surface two times. They are waiting for drying and rolled with paint using a roller.

Locks for wickets

The wicket is exposed to temperature extremes, humidity and atmosphere. The peculiarity of the lock is a narrowed bar and a short interval from it to the axis of the lock.

More than half of the users choose a mortise lock. Padlocks belong to the category of unreliable constipation and are placed in summer cottages and garden plots. Rack locks include a bolt that slides in loops. The surface lock is reliable, for its installation you need a drill and welding.

Electromechanical locks consist of a shutter device and a control panel; electricity is required for operation, as for an electronic lock. The radio wave lock works on the principle of a car alarm and is difficult to break.