The frame for the building can be erected not only from a bar or planks, but also from a profile pipe. The technology is used for the construction of industrial and commercial buildings, where the speed of installation and strength are important, and not beauty and comfort. However, a rectangular pipe is also used in private construction.

Advantages and disadvantages of houses with a metal frame

The main advantage of frame buildings is the ease and speed of construction. But when building a country house, the cost of the project is important. To a greater extent, it is determined by the type of foundation. Therefore, from a metal profile, they build cottages with a height of no more than 2 floors with their own hands. Otherwise, this advantage is lost.

They use galvanized steel and aluminum pipes. The first option is stronger, but the second is more resistant to corrosion.

The frame of the house made of a profile pipe has the following advantages:

- short construction time - a residential cottage with a foundation is being built in only 2 months;

- immediately after construction, the house can be finished and settled, since metal structures do not shrink;

- the building is light, therefore it requires a light foundation: pile, screw, shallow tape;

- metal is more durable than wood, a house with such a frame will last longer;

- the cost of the building is lower than a traditional house made of timber, and even more so a brick.

Minuses:

- Complicated calculations - before construction, it is necessary to accurately calculate the load and select pipes of the optimal cross section. An excess of strength in this case only leads to unnecessary costs.

- The installation of a metal frame is more difficult. The ability to weld metal structures is required.

- Steel and aluminum conduct cold, so the thermal insulation qualities of a house with a metal frame are noticeably lower than buildings with a wooden one. Additional insulation is needed.

In modern buildings, pipes are not welded; they are bolted to crabs.

Calculation of the required amount of material

A house made of a professional pipe requires accurate and complex calculations. The main bearing load in it is carried by the frame, therefore it is very important to take into account all the factors acting on it:

- dimensions - the width, height, length of each wall or each architectural element;

- weight - includes the mass of the frame, floors, finishes, insulation, furniture, plumbing and equipment;

- wind, snow, rain loads inherent in this region - this information can be gleaned from reference books, in the calculations it is necessary to take into account not only the absolute values, but also the nature of the structure: the angle of inclination of the roof significantly affects the total load.

After the calculations, a skeleton scheme is developed taking into account the selected materials. Calculate the load on each element. If the result is not satisfactory, the framework is changed.

The next stage is the calculation and creation of drawings of each structural element - columns, floors, partitions, purlins. All corners are marked.

As a result of the development, a set of working drawings is formed, where detailed diagrams of each unit are described, materials are indicated, etc.

Required tools

To erect a building from a professional pipe, you need the following tools:

- welding machine, if installation is carried out by welding;

- screwdriver;

- a grinder with a diamond disc, a hacksaw for metal;

- tape measure, square, plumb line, tap;

- fasteners - bolts, nuts, screws, crabs.

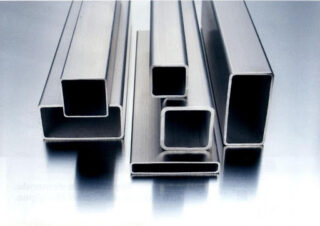

Of the materials, a square and rectangular pipe of the required section is needed.

DIY house frame construction

For a frame made of a professional pipe, a columnar or shallow strip foundation is made. The finished base is waterproofed. After that, construction can begin.

- They put the bottom harness and columns. Corner posts are attached first, bolting to the foundation. A more reliable method is welding. In this case, special pins are embedded in the base, and racks are welded to them.

- Intermediate vertical elements are placed at such a distance from each other so that in the future, a finishing element is placed between the racks - a self-supporting insulated panel, a shield.

- A harness is attached to the foundation. For him, take a large section profile - 100 * 100 or 60 * 60 mm.

- Vertical racks are interconnected by horizontal jumpers, reinforced with braces. If the racks on the foundation were fixed by welding, all other fasteners are performed in the same way. If not, crabs and bolts are used to hold the structures together.

- At the level of the future overlap, an upper trim is installed. It also needs a larger pipe.

- For ceiling beams and logs, a profile pipe is also used. It is recommended that you make a rough flooring immediately.

- The whole frame is erected. If a 2nd floor is envisaged, the vertical racks are immediately set to the required length. In such a project, the second floor cannot be completed.

- A reinforced channel is placed under the roof on top of the upper trim. Roof trusses are laid on a Mauerlat and fixed - with bolts or welding. The cross-section of the pipes is selected taking into account the weight of the roofing material. For a roof made of ondulin or profiled sheet, small-section pipes are taken; for slate or tiles, elements of a larger section are required.

- All joints and attachment points on a metal frame must be additionally treated with primers or paint to protect against moisture.

A house with a frame made of a profile pipe is more reliable and durable compared to the option on a wooden frame. However, such a building needs additional insulation, since the metal structure conducts heat well.