Brick is a popular building material. The processed clay is especially appreciated in Russia and European countries. The material is used not only for the construction of houses, but also for the construction of a fence.

Advantages and disadvantages of the design

Of all the fencing structures, the brick fence looks the most beautiful. It provides protection, brings artistic flavor to the landscape of the territory. Serves for many years without losing its positive characteristics. Belongs to the category of expensive structures. Usually done in red or gray.

Like any other option, a brick fence has its own advantages and disadvantages. The disadvantages of the structure include the high cost, as well as the long duration of the construction.

Fencing structures based on brickwork have two positive indicators: they look prestigious and can be combined with any materials. Fences for a private house made of bricks look especially harmonious. Suitable for simple country buildings, wooden cottages.

Also, the positive characteristics include:

- Opacity. The visual component plays a big role. In addition to protecting against the penetration of strangers, the fence provides protection from prying eyes.

- Fortress. High quality bricks are durable, resistant to adverse weather conditions. Mechanical damage to the masonry is impossible.

- Ease of use. The structures do not need special maintenance, anti-corrosion treatment and periodic painting. The only requirement is to cover the structure with a waterproofing compound.

- Variability. The construction of a structure is possible in various ways.

Having invested money once in such a structure, you can forget about the need for its alterations and repainting. The old brick fence will keep its fortress.

How to choose a brick for a fence

The following is taken into account:

- high level of strength;

- low moisture absorption;

- color fastness.

For the construction of fences, the following types of bricks are used:

- ceramic;

- clinker;

- silicate;

- hyper-pressed.

Each type is distinguished by its own production characteristics, unique technical parameters. There are many products of various price categories on the market. It is recommended to carefully study the features of the product before purchasing.

Facing brick

Facing bricks are produced without firing. It is full and hollow. The mass of material is compressed under high pressure. The composition does not include sand and clay. Crushed limestone is used. Cement is used as a binder. A facing brick fence is not highly resistant to moisture. Made in various color variations.

A light brick fence for cladding looks very attractive. The material is in high demand on the market.

Chipped brick

Chipped bricks can be processed by hand. It acquires a unique relief resembling a stone.

Mechanical chipping is achieved by processing bricks on a special machine. The material acquires a torn "classic" surface, does not have sharp protrusions. The masonry gives the structure a casual look. The cladding favorably emphasizes all the advantages of the fence.

The sawn chip represents a smooth, non-standard cut. The cutting site acquires the structure of marble due to the addition of small stones to the brick. The split brick fence is highly durable. Combines with any building materials. Shows resistance to moisture. Differs in a high price.

Ceramic

Ceramic bricks are made on the basis of red clay. The product is brown in color. It is one of the most common types due to its low cost. Combines well with other materials. It is made by pressing clay or flexible molding. The product has a high hardness and resistance to moisture.

Silicate

The basis of the product is quartz, limestone or minerals. Available without holes. It is more often used for interior construction, but it is also applicable for the construction of fences. The material has an average level of strength. Differs in a high degree of reliability and resistance to moisture.

Clinker

Gives the masonry an elegant look. Differs in texture and color resolution. Suitable for fence and cladding. It is made from shale clay. Differs in a high degree of strength. It does not have voids and does not lose its qualities for many decades. Does not allow moisture to pass through. The production technology is complex. An expensive mortar is used for masonry.

Hyperpressed

It is made on the basis of cement chips, lime and marble. It is considered an environmentally friendly product. Does not allow moisture to pass through. Possesses compressive strength and strict geometric shape. All components of the product are tightly bound under the pressure of a special press. The brick is made in a different palette. You can often see a gray brick fence. It has a chop and a smooth texture. Differs in high cost.

General construction procedure

Step-by-step instruction:

- Site preparation and marking. The proposed line of the future fence is being cleaned. Trees, bushes and weeds are uprooted. Old fences are being removed.

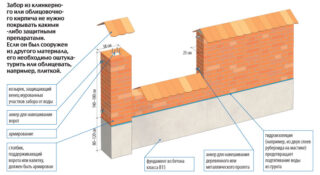

- Arrangement of the foundation. A trench is being dug along the perimeter of the site for laying the fence. Its width and depth depend on the parameters of the structure. In the places where the pillars are installed, the indicators differ, since reliable support is required. The bottom is covered with a sand or gravel cushion, after which a reinforcing cage is erected. Steel piles are vertically fixed at the points of installation of the supports. After that, formwork is erected on both sides of the trench. For this purpose, building boards, beams, and laminated plywood are used. The final stage is the pouring of concrete.

- Laying of pillars. Construction begins after the concrete mixture has completely solidified in the foundation. For engineers, the width of the posts is usually two bricks. A void remains between the masonry and the metal pipe, which is filled with a liquid cement mortar. When erecting the pillars, their verticality and the same levels on the perimeter lines are provided. If a combined structure is being built, embedded metal and wood are used. When building a solid fence, reinforcing bars are inserted into the supports, which will serve as a bundle for the structure.

- Filling spans. When erecting a solid fence, the basis of the span is a brick. When performing a combined fencing, sections are hung on embedded parts or logs are mounted for corrugated board or other material.

- Installation of decorative elements.Usually, concrete or iron caps are laid on the pillars. When constructing a continuous fence, special parapets are attached to the cement-sand mortar. These products act not only as decorations. They serve to protect the upper edge of the masonry from rain and snow. If other decorative ornaments are provided, their installation is also carried out at this stage.

- Hanging gates and wickets. This is the final stage in the construction of a brick fence, which is ready for use. Any material is suitable for the manufacture of gates. Most often these are welded structures or forging. When erecting combined fences, the material from which the spans were made is usually used.

A fence made of red or gray brick is combined not only with forging, but also with wood, stone and metal profiles. The versatility is so high that even gates and wickets made of polycarbonate look harmonious with such structures.

In order to increase the decorative function, designers advise using curly or multi-colored masonry, as well as complementing the design with stylish columns. The result is a beautiful brick fence.