Clinker tile is a material for exterior and interior decoration of houses; it is used to repair damaged brickwork and restore walls. Facade tiles are used for external insulation with thermal panels, they are placed as cladding. The peculiarity of the material is that it can be used when a full-fledged brick cannot be fastened, while the elements are thinner and lighter.

What is clinker tiles

Finishing elements are represented by details with a thickness of 9 - 25 cm, which imitate brick ceramic masonry. Highly plastic clays are used as raw materials. The production includes pressing of refractory grades and roasting in furnaces at + 1300 ° C.

The standard dimensions of rectangular clinker facade tiles are 120 x 245 mm, but the elements can be of irregular shape or large dimensions.

The cladding is combined with brick, wood, concrete, polyurethane foam, thermal panels and is firmly glued to them. Variety is produced according to texture, color for choice.

Varieties of clinker tiles

Glossy, rough tiles of different shades allow you to create a harmonious facade of the house, complete interior decoration and serve as a road surface when creating a courtyard landscape.

Types of clinker finishes by purpose:

- facade elements used with and without insulation;

- for covering the steps of the porch and basement;

- elements with imitation stone for various applications;

- for finishing inside buildings;

- decorative types;

- paving slabs.

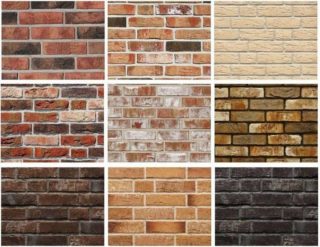

Most often, the surface of the elements is not coated, so the cladding looks like a natural brick. There are many color options, they are obtained by adding certain types of clay, the temperature regime is changed. The glazed surface provides a beautiful effect and prolongs the working time.

Under the brick

It is a durable tile that resists impacts. Refractory shale is taken as raw material, chemical additives are not included in the composition. Used for cladding facades and plinths. The material is characterized by minimal moisture absorption - no more than 6% of the mass.

The clinker facade can withstand temperature extremes, frost and heat, does not fade when exposed to UV rays, its original appearance remains for decades. Mold, fungi do not develop on the material, microorganisms do not live.

For basement, porch, steps

The entrance group to the house is faced with finishing grades of clinker and paving slabs with high abrasion resistance are used. The result is a reliable and durable base that does not undergo cracking in severe frosts and intense heat in summer.

Tile sizes for steps:

- dimensions 200 x 200 mm, 300 x 300 mm, 330 x 330 mm;

- the thickness of the parts is 20 mm.

The tiles are placed on moisture-resistant and frost-resistant glue. The surface of the finishing elements does not slip, it is safe for people to move in the open space.

Under the stone

The version with imitation of natural stone is used in interior decoration and for installation on the facade. Varieties are combined for a more expressive play of contrasts of various materials. The surface is made to look like marble, granite, sandstone, slate.Often, facade clinker is placed under the stone for finishing the basement, so that the structure is visually perceived as a solid and indestructible foundation.

Such tiles have small pores, so they do not absorb water from the soil. Elements under the stone are durable, so they are placed on stairs, the floor of verandas and terraces, rooms where many people walk.

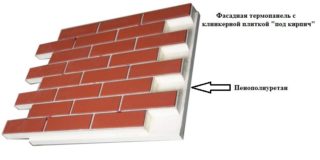

With insulation for the facade

The tiles are ideally located on the facade and protect the insulation from moisture, wind and insolation. Tiles are placed on a thermal panel 2 times faster than on an ordinary layer of insulation.

For interior wall decoration

The microclimate in the house is different from the outside, so the tiles have a minimum thickness of 8 mm. For such a finish, the requirements for wear resistance and bending strength are reduced, since the internal surfaces are not subjected to such loads. The requirement for decorative surface coating and the weight of the facing elements comes to the fore.

For bathrooms, toilets, saunas, kitchens and showers, tiles with increased water resistance and resistance to fat and chemical elements are installed so that the surface does not collapse from harmful substances.

Decorative

A picturesque clinker is placed on columns, stairs, fireplaces, wall sections are trimmed, door and window openings are framed.

Varieties of decorative tiles:

- technical for cladding laboratories and workshops with the release of aggressive components into the environment;

- common for walls in residential buildings;

- waterproof for finishing walls and floors in the premises of the pool, bath.

Heat-insulating clinker with minimal porosity is used if it is not possible to supply external insulation. It is pre-dried to the boundary state in order to reduce the number of air gaps inside.

The clinker is widely used, but in each case it is necessary to take into account the purpose of the material for a specific purpose. The price category determines the quality of the product; you should not save on it. By color, there are natural shades, lightened, peach and dark colors, so this factor is also paid attention to.

Advantages and disadvantages

Installation of clinker for the facade can be carried out at any time of the year, while there are no whitish efflorescence on the surface, which may appear during the crystallization of salts.

Positive qualities of the material:

- low water absorption, from 1 to 6%;

- frost resistance;

- easy care;

- wear resistance and strength;

- durability.

Clinker tiles are made from natural ingredients, therefore they belong to the category of environmentally friendly materials. The quality is maintained even when heated by the sun, while no harmful emissions into the atmosphere occur.

The disadvantages include the high cost of the material. Due to its low water absorption, the clinker requires the use of a special adhesive.

Do-it-yourself facade cladding technology

For the device of the finishing layer, you will need tools that are purchased in advance.

List of accessories for work:

- grinder with a circle on a stone;

- serrated hammer for notching, trowel for applying glue;

- joint filling gun, serrated trowel;

- usually level, plumb line, tape measure, rubber mallet.

For the sticker, a special-purpose tile adhesive is used, which is used for interior or exterior decoration.

Preparation

Check the straightness of the wall or the horizontalness of the floor, steps. The surface is leveled with plaster, large protrusions are knocked down. Smooth surfaces are notched for good grip.

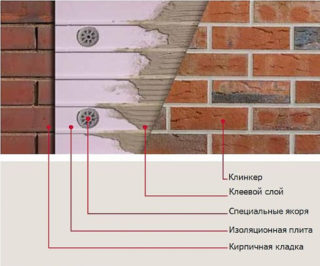

Insulation is installed on the surface, if such a layer is provided by technology, then waterproofing is attached. To install the tiles on the mortar, the first layer of plastering is used, in which a reinforcing mesh is installed. The surface is smoothed during the application of the solution.

Installation

Work order:

- make a preliminary marking of the prospective rows;

- pull the sequential thread for control;

- glue is applied to the surface with a trowel and smoothed on the base;

- the laying starts from the openings of the window or door, if there are none, then from the corner of the wall, they make a trim, if necessary;

- the installation of the tiles is checked by the level, the uniformity of the seams is monitored.

The intersection of the seams is done crosswise or the tiles are set with an offset. In the second case, the elements are shifted so that the middle of the second row of bricks falls on the seam.

Grout

The process belongs to the final stage. The joint compound must be tight to prevent moisture penetration under the clinker. Use a filler gun or use a tight plastic bag with the corner cut off. For sealing, jointing is used, which also makes the form of the joint mortar for hardening.

Sometimes a metal rod with a thickness of 6 - 8 mm is inserted into the seams during laying. If it is laid evenly, the grout is easy after removing this element.

Top manufacturers

ABC produces structured, glazed clinker tiles in over 50 shades. The products meet all required standards and have quality certificates.

Roben production is located in many countries in Europe and the world. The company offers on sale over one and a half thousand types of products, including clinker. The facing material is available for various purposes. The company has received many awards and prizes.

Clinker Bud, a Ukrainian supplier of clinker finishes, is a direct supplier of European brands.

The Russian manufacturer Keralite produces outdoor clinker. The products are characterized by durability, wear and impact resistance.