The roof is a complex engineering system, consisting of many parts and structures, each of which serves a specific task. The combination of parts provides the entire structure with sufficient strength, stability and tightness. Thanks to the creation of reliable protection against environmental influences, a comfortable, healthy microclimate is created and maintained in the premises. One of the parts of the rafter system is the roof counter-lath.

Purpose of counter battens and differences from battens

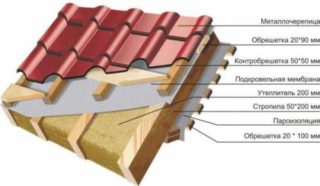

The lathing and counter-lathing is a set of slats that are installed over the rafter legs over the entire roof area. With the consonance in the name and similar appearance, both buildings perform completely different functions.

The lathing is used to accommodate the roof covering. Depending on its type, solid and sparse options are selected. The base is made of slats, boards or shields (when working with roofing felt and soft tiles). The lumber is nailed or screwed onto the longitudinal battens.

The counter-lattice on the roof is designed to create a free space between the roofing and layers that perform the functions of insulation and waterproofing. Thanks to this solution, air circulation occurs under the coating, and the unhindered removal of moisture and unwanted odors is ensured.

Both structures are made of the same material and are an integral part of the rafter system. The counter lattice is large, this is dictated by the need to create free space.

In all cases, the installation of both designs is mandatory. This is the only way to achieve the optimal combination of assembly strength and ventilation quality in the attic.

Installation of roof battens and counter battens prevents the following problems:

- Loss of roof insulation properties. Wet material allows heat and cold to pass through much better.

- Damage to insulation. In the wet layer, fungus and mold grows, destroying any materials over time.

- Destruction of the rafter system. Wood absorbs steam from condensation well. Because of this, the timber and boards lead, they rot and break.

- Deterioration in the appearance and quality of the topcoat. Dampness adversely affects all types of finishes, causing stains, corrosion, and weakening of strength.

You should not skimp on lumber when building a pitched roof. The investment will pay off with the durability of the structure.

Material used

As a rule, roof counter battens are made of square or rectangular beams. The type of wood is selected based on what the building will be covered with. For heavy coverings (ceramic tiles, copper sheet, corrugated board, slate), it is better to choose hard species - oak, cedar, larch. If the decision is made in favor of a light coating (soft tiles, roofing material), it is advisable to use soft and light varieties - spruce, pine.

When buying, you need to pay attention to the quality and condition of the goods. The timber should be well dried (no more than 20% moisture), without cracks, large knots, curvature. The presence of rot, mold, places affected by insects, any stains is not allowed. The connection of the parts is carried out with galvanized roofing nails 100-150 mm long.

In rare cases, a counter-lattice for metal tiles for a cold attic is made of a metal profile. Such structures are distinguished by their high strength, durability and considerable cost. The profiles are fastened by welding, bolts or self-tapping screws.

Roof pitch and size

Most often, the counter lathing on the roof is made of a bar with a section of 25x30 mm. If the area of the slope exceeds 50 m², a bar with a thickness of 50 mm is taken. This option improves the ventilation quality of the entire system. Counter battens on the roof are nailed onto the rafters, or rather, onto a membrane film fixed to them, under which there is a heater. Two tasks are solved at once: effective removal of moisture from the attic and a snug fit to the base of insulating materials.

The counter-lattice step corresponds to the distance between the rafter legs. At the same time, the timber is the basis for installing the lathing for the format of the fragments of the finish coating. Each of them is accompanied by instructions for determining the distance between the slats.

Installation instructions for metal tiles

The installation of the counter-lattice is performed according to this technique.

- Carrying out measurements, drawing up a diagram, material requirements.

- Marking, preparation of blanks.

- Wood treatment with antiseptic and fire retardant.

- Laying insulation between the rafters.

- Sheathing of the frame with a membrane film.

- Fastening the counter-lattice.

- Installation of the lathing to the size of the metal tile.

- Laying of roofing material. This process is carried out from the bottom up. At the junction of the slopes, a gap is left for installing the ridge with aerators.

- Interior decoration of the attic. Fastening membrane and wall panels.

In conclusion, the installation of additional parts is carried out. Depending on the design of the roof, pediment strips, abutments, ridge, corners and valleys, ebb tides, adapters, gutters, snow holders, adapters and seals are used.

The construction of a cold roof is carried out without the use of insulation. Moisture enters the room through the floor slab, microscopic cracks, and is released from the wood. All this leads to the formation of condensation, which negatively affects the supporting structures and the cladding. Cold attics require the installation of a counter batten, which will provide high-quality ventilation and moisture removal from under the roof.