The heating system of private cottages is most often autonomous. It is more convenient: the owner of the house independently determines the heating mode, controls the fuel consumption and regulates the work. The main heat source in the system is a gas boiler. For him and for his periphery, it is recommended to equip a boiler room in a private house.

- The purpose of the boiler room

- Main regulatory documents

- Rules for placing a boiler room in the house

- Requirements for the premises

- Requirements for a boiler room attached to a house

- What area should the room be

- The size of the pellet boiler room in the house

- Placing the boiler in the kitchen, pantry or hallway

- Boiler room window

- Boiler room door requirements

- Requirements for the walls in the boiler room

- Design and calculation

- Air exchange

- Supply and exhaust flows

- Electricity

- Heating project composition

The purpose of the boiler room

Heating equipment is classified as unsafe in an emergency. If a gas boiler or supply pipes leak, there is a possibility of fire, explosion, fire and poisoning. Therefore, it is necessary to mount such equipment in accordance with the norms of SNiP.

The best way of arrangement is a separate special room for a gas boiler and its servicing equipment. They build it so that in case of damage, accidents or during repairs, people living in the house, as well as living quarters, are not affected.

Places for placement:

- attic or attic;

- basement - by far the most popular solution;

- separate utility block - recommended if the house is old;

- room in the house;

- attached boiler room.

The design of a boiler house based on a gas apparatus and on the basis of an electric boiler is coordinated with state organizations.

Main regulatory documents

The basis of regulatory documentation for the construction of a boiler house is SNiP documents. The list includes:

- paragraph 6.17-25 in SP 42-101-2003;

- clause 6.29-48 of the joint venture dated 2.04.08-87;

- chapter 4 in SP 41-104-2000;

- clause 7 of SP 62.13330.2011;

- clause 6.6 of SP 60.13330.2012;

- clause 6.12 of SP 55.13330.2011;

- instruction MDS 41.2-2000 on the placement of gas boilers.

SNiP norms are constantly updated and changed. Since 2019, equipping a gas boiler room with a gas pollution sensor has become a mandatory element.

Rules for placing a boiler room in the house

It is better to entrust the development of the boiler house project to specialists. In addition to SNiP norms, there are many additional restrictions on the size of the room and its arrangement, regarding fire safety, requirements for the frequency of air exchange, and operating features.

The choice of the room is influenced by the power of the heater:

- If the power of the gas boiler does not exceed 30 kW, it can be installed anywhere, including the kitchen and corridor.

- Equipment with a capacity of up to 60 kW can also be installed in the kitchen or in the hall, but compensate for the insufficient air exchange with a supply duct with a minimum diameter of 15 cm.

- The device, with a capacity of 60 to 150 kW, is mounted only in a specially prepared room.

- Even more powerful units are installed only in a separate building.

If in a special structure everything is arranged for the correct placement of the boiler, then in the utility compartments or in the basement it is necessary to take into account the peculiarities of the installation and design of various systems. The gas boiler is mounted on the floor or on the wall. At the same time, it is allowed to mount a device up to 60 kW on the wall in the kitchen, and only up to 35 kW in the hallway.

A single-circuit boiler only works to heat the house, a double-circuit one supplies hot water.This option is chosen if a small amount of hot water is used. Then the boiler room also replaces the boiler room.

Requirements for the premises

The room for a gas boiler must fulfill a number of the following conditions.

- There should be a window in the stoker. It can be either plastic or wooden. Its area is calculated from the proportion - 0.03 m² of glass per 1 m³ of the room. Therefore, they build a boiler room in the basement only if the utility block belongs to the semi-basement rooms.

- Ventilation is required. The power and type of system depends on the parameters of the boiler.

- The unit is supplied with water and sewer pipes, gas pipes, control systems, and electrical wiring. The equipment must be located so that there is free access to the boiler and to any heating element.

- Sheathe walls, floors, ceilings can only be done with non-combustible materials. For walls and floors, tiles are usually taken, plastering is allowed.

- It is allowed to install no more than 2 devices in the boiler room.

- The weight of the boiler is taken into account. If it exceeds 200 kg, a reinforced concrete cushion or slab foundation is erected under it.

- All openings must be finished with non-combustible materials, the sashes must open outward.

- All elements of the heating system must be freely accessible.

It is preferable to install boiler rooms in the northern or eastern part of the house. Usually they are combined with a bathroom, boiler room, kitchen.

Requirements for a boiler room attached to a house

A separate module can be built for the stoker. This option is rarely resorted to, since usually the extension distorts the appearance of the building. However, if the equipment to be installed has high power, there is no other way out.

There are a number of special requirements for the extension:

- The foundation of the structure is not connected to the foundation of the building, a gap is left between them, and is often additionally waterproofed.

- Gas appliances get very hot, so the walls, floor and ceiling are made and finished with only non-combustible materials.

- The foundation for the extension is a slab with a height of at least 20 cm.

- A special foundation is required for the chimney.

A separate or attached boiler room, like the room in the house, is equipped with its own hood. Windows are required.

The construction of attached and roof-top boiler rooms is allowed if the standards for water pressure and temperature are met.

What area should the room be

The dimensions of the boiler room in a private house for a gas boiler are regulated by SNiP. The parameters are determined by the power of the equipment.

The rules are as follows:

- With a power of up to 30 kW, 7.5 m² is required to equip the unit for gas. The height of the room is about 2.5 m, therefore, when installing in the kitchen, you need to calculate the air exchange rate.

- A 60 kW heater requires 15 m³.

- The area of the boiler room in a private house for a gas domestic boiler with indicators up to 150 kW is 15 m² with a height of at least 2.5 m.

- The cubic capacity of a stoker for a unit with a capacity of up to 350 kW is at least 20 m³.

In fact, the area of the room should be larger. After all, next to the unit, it is necessary to place service and measuring equipment so that free access to any elements and apparatus remains.

If the boiler is placed in a wooden building, the distance from the unit to the wall upholstered in this area with iron is at least 40 cm.

The size of the pellet boiler room in the house

If there is no centralized gas supply, a pellet boiler is installed instead of a gas boiler. This solid fuel option attracts with its efficiency and automation capabilities. Pellets can be stored in a special hopper, from where they are fed into the boiler as needed.

The bunker and the heater are placed in different rooms or behind partitions. The dimensions of the compartments depend on the dimensions. Usually the bunker does not exceed 6 m³. This is enough for heating 400 m².within 6 months. The storage area requires 4 m². The dimensions of the boiler room are calculated in a standard way.

The location of the bunker and the pellet boiler in the same room is prohibited. According to SNiP requirements, a bunker with a volume of more than 0.8 m³ is mounted in a separate compartment.

Placing the boiler in the kitchen, pantry or hallway

If the power of the device does not exceed 60 kW, installation in utility rooms in the house is allowed. Gas services permit installation if the cubic capacity of the kitchen is 21 m³ or the kitchen-dining room - 36 m³.

Both floor-standing and wall-mounted boilers are installed here. Equipment - pumps, mixers, distributors, manifolds, usually try to be fixed above the apparatus and camouflaged with a cabinet. Apart from the requirement of free access, there are no restrictions on the installation.

The advantage of this location: there is no need to bring the chimney to the roof. It is enough to bring the pipe to the facade.

It is strictly forbidden to put the gas boiler in the bathroom or in the bathroom.

Boiler room window

Its purpose is to protect the building from an explosion. In an accident, the shock wave knocks out the window and, due to this, the supporting structures of the house are not damaged.

The glazing area is calculated based on the parameters of the room:

- with a boiler room area of up to 9 m², a window with an area of at least 0.8 m² is installed;

- in a room of more than 9 m², the area of glass is not a frame, calculated from the ratio - 0.03 m² per 1 m³.

Instead of LSK glass, it is allowed to install a single-chamber double-glazed unit up to 4 mm thick. Polycarbonate, safety glass, reinforced glass cannot be used.

Boiler room door requirements

The door must be equipped in the attached boiler room. From the premises inside the cottage - in the basement, in the kitchen - a separate door is not needed.

The exception is the boiler room for pellets or wood. Here access to the street is necessary.

The requirements for the door to the home boiler room are as follows:

- the distance from the door to the room to the front door should be no more than 12 m;

- the sash should open outward to facilitate exit from the boiler room;

- the width of the door leaf exceeds the width of the boiler by 20 cm;

- the leaf must correspond to type 3 with EI15 - steel door with non-combustible filling;

- the threshold in front of the entrance should be 10 cm higher than the floor in the corridor to prevent flooding in the event of a leak.

A sewer ladder is installed to drain the water.

Requirements for the walls in the boiler room

For attached or separate modules, certain building codes are also presented. Walls are built only with load-bearing or self-supporting materials - brick, foam concrete, aerated block. Such material can withstand open fire for 120 or even 180 minutes.

The bearing load is also taken into account. The weight of boilers and expansion tanks is quite heavy. A brick wall will withstand such a load.

Frame technology and sandwich panels are not suitable, since the materials used in construction are combustible.

Design and calculation

It is better for a specialist to create a project and calculate the layout of the boiler room. However, the owner must be familiar with the general requirements of the organization.

Air exchange

The frequency of complete air renewal depends on the purpose of the room. In the kitchen, the air must be completely renewed in 1 hour, but taking into account the fact that an additional 100 m³ is required for the operation of the gas stove. If we are talking about a separate boiler room, the air is renewed three times per hour. However, in this case, the air exchange must be calculated taking into account the volume of supply air for gas combustion.

Actually, the calculation is simple. For example, for normal air circulation in a boiler room of 12 m² with a height of 3 m, 12 * 3 * 3 = 108 m³ of air per hour is required.

Supply and exhaust flows

The inlet is placed at the bottom of the door or wall.It is better if the air enters the room from the street, but it is also allowed from inside the house. The dimensions of the hole are determined by the power of the boiler, the dimensions of the room and the type of unit. So, for a solid fuel boiler with a closed firebox, only three-fold air exchange is considered. For the model with an open hearth, the combustion air is taken into account.

It is allowed to perform the calculation taking into account only the area of the house.

The exhaust shaft is usually located next to the chimney. A prerequisite is that the hood must be brought out to the roof of the building, otherwise there will be no draft in the ventilation.

Do not install the fan in the exhaust duct.

Electricity

The wiring into the boiler room is started in the usual way. It is recommended that electrical cables are embedded in walls. With a high power of the heater, it is better to connect it through a separate shield.

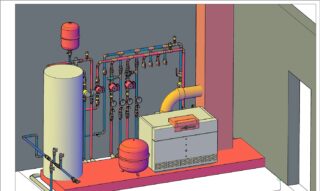

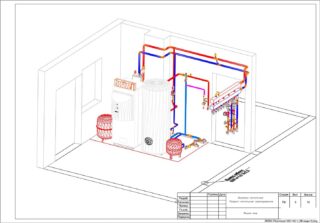

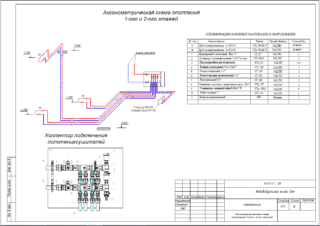

Heating project composition

- the plan of the heating system and underfloor heating, if it is equipped;

- axonometric diagrams of both systems;

- drawings of serial pipeline connection and fastening assemblies;

- thermal diagram of the boiler room;

- foundation plan, if any;

- chimney laying diagram;

- layout of boiler equipment;

- specification of equipment and materials used;

- general drawings.

Boiler room for a gas boiler - a special room. It is equipped with its own hands in accordance with a number of very strict rules. Fire safety, sanitary standards, air exchange requirements, boiler operation rules are taken into account.

My boiler room 31 kW is a cabinet in the kitchen.

The author constantly, both in the text and in the video, confuses m3 with m2)