There are several ways to make your home more spacious, more comfortable, and more attractive. One option is to build a bay window. The structural element is erected simultaneously with the walls or added later. The construction of the roof of houses with a bay window is approached responsibly. You can do the work yourself if you know the design features and the procedure for carrying out the work.

Purpose, advantages and disadvantages of bay windows

A bay window (German lantern) is a rectangular, semicircular or polyhedral ledge in the wall of a building that increases the volume of rooms. The element is usually built over several floors, except for the first.

A roof with a bay window can be made as a whole with the entire roof or as a separate part.

The bay window performs several important functions:

- increases the useful area of the building - the walls of the "lantern" are most often made insulated;

- improves illumination of the interior space due to the large glazing area;

- gives the building an attractive appearance.

Among the disadvantages are increased heat loss and construction costs.

Bay window requirements:

- mechanical resistance to wind gusts;

- streamlined appearance for timely drainage of precipitation;

- manufacturability of construction;

- the possibility of insulation for the use of the premises at any time of the year;

- minimal loads on the foundation - due to the absence of a capital pediment;

- high-quality glazing to reduce heat loss.

The shape of the bay window itself is chosen, taking into account the way of arranging the roof, materials of manufacture.

Bay windows in the form of small ledges are used for offices or for placing outstairs stairs. Lanterns along the entire wall of the house are suitable for arranging full-fledged living rooms, kitchens, living rooms.

By shape, they distinguish semicircular, rectangular, trapezoidal, triangular and multifaceted structures - the choice is based on the tasks and design of the facades.

Roof types

For bay windows, roofs with a different number of slopes are used.

The single-pitched version is suitable for rectangular bay windows and is performed as an independent structure or a structure combined with the main roof of the building.

The gable view is appropriate in cases where the roof is of the gable type - a single style will be observed.

A four-pitched hip roof with a bay window is used for "lanterns" in the corners of buildings. They are often made in the form of small turrets.

Roof design options

In the general classification, there are several roof options suitable for bay windows:

- Tent. It can consist of several slopes or be made in the form of a tent and smooth lines of bends. For the calculation, you will need confident knowledge of geometry, since accurate calculations are required when cutting the material. One of the design options is the cone, which is best suited for rounded bay windows.

- Hip. For outbuildings on the wall, three slopes are more often used. Suitable for rectangular and multi-faceted bay windows.

- Multi-pliers. The bay window roof plays the role of one of the tongs of the general roof of the building, a gable version is used.

When installing the roof yourself, the complexity of the work and construction skills are taken into account.

Installation steps

Arrangement of the roof of a bay window of any configuration is carried out according to similar algorithms:

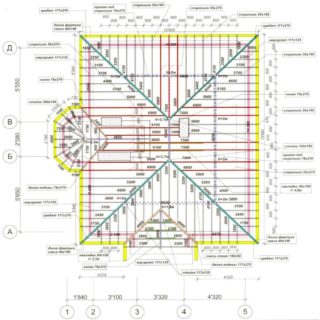

- Draw up a project or make an accurate drawing.

- Prepare materials for the frame, insulation cladding and fasteners.

- They mark and cut the materials for the rafters.

- Prepare the rafter system.

- Sheathing is carried out with roofing material.

- They insulate the structure and hem the inner layer.

- Finishing is carried out.

Mounting technology may vary depending on materials.

Design

The correct design helps to know exactly the amount of required materials for the roof.

Purchasing a smaller quantity will incur additional shipping costs. The seller may run out of material, and a new batch will often differ in color. Buying excess material is a waste of money.

For self-production of a drawing:

- Accurate measurements of the building are carried out - the length of the walls along the entire perimeter.

- Select the required roof height, which can be done at the construction site.

- Using geometric formulas, they calculate the required amount of lumber, roofing and filing material, insulation and vapor-waterproofing membranes.

When determining the slope, allowable values for various materials are taken into account.

Building directories recommend minimum angles in degrees:

- ceramic tiles - from 15;

- metal and bituminous tiles - 12;

- fiber-cement slate, profiled sheet, folded version of sheet metal - at least 20;

On roofs with a lower slope, snow accumulates, making the structure heavier, and melt water can flow between the outer sheathing sheets.

Assortment of materials

For the rafter system, a coniferous timber is purchased - it is cheaper, but has sufficient strength. The section of lumber is from 50x100 mm for small roofs and up to 80x200 mm for large buildings.

For the lathing, choose a board with a thickness of 25 mm or an OSB board. The plywood option is applicable, but expensive.

Any roofing material is suitable for external roof cladding: slate (cement, bituminous), metal tiles, roll products, soft tiles. They are guided by what the main roof is made of.

Foamed or extruded polystyrene, stone wool are used as insulation, sometimes liquid thermal insulation is used. The inner surface is sheathed with clapboard, OSB panels or plywood, drywall.

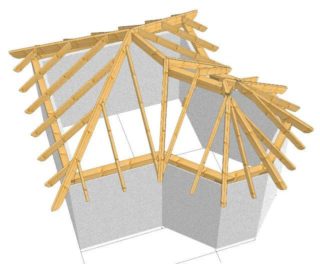

Construction of the truss system

There are two options for building the system:

- on the roof - in place - the structure is assembled by experienced builders:

- marking, fitting, assembly of individual elements on the ground with subsequent ascent to the bay window.

The second option is more suitable for independent work. So it is more convenient to measure and adjust the rafters.

Between themselves, the logs are fastened with self-tapping screws through the corners or knocked down with nails.

To fasten the roofing material to the rafters, the sheathing is attached.

Features of the installation of external cladding

For soft roofing materials, the sheathing is continuous. Use sheets of OSB, plywood or edged boards.

The material of the lathing and rafters must be treated with an antiseptic and a fire retardant compound. An act on the implementation of these works will be required to put the house into operation.

Cement slate, profiled sheet and metal tiles are allowed to be laid on a sparse crate.

Fasteners of the finishing coating are carried out with roofing screws, for slate - with nails. When choosing hardware, the recommendations of manufacturers are taken into account.

Warming and waterproofing

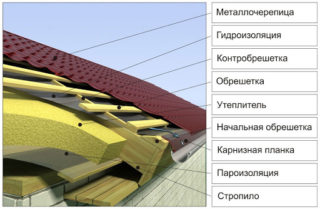

The composition of the roofing pie starting from the room:

- filing;

- vapor barrier;

- insulation;

- hydro-wind insulation;

- crate;

- finishing outer skin.

Places of loose fit of the insulation to the rafters are sealed with polyurethane foam.

Vapor barrier is necessary to prevent condensation from entering the insulation - stone wool loses its properties, quickly cakes.

To protect the internal space from precipitation and drafts penetrating under the roof, hydro-wind insulation is installed. Use membranes made of nonwoven materials or roofing material.

Finishing

Finishing work completes the bay window roof. The lining is covered with varnish or paint. Drywall is plastered, painted, covered with wallpaper.

The roof of houses with a bay window has an irregular shape. The construction will require additional costs and a lot of experience if the work is carried out on their own. It is necessary to objectively assess the skills and, if in doubt, entrust the construction to professionals. The reliability of the structure and comfort in the house will depend on the final result.