The hills and lowlands in the garden area are often considered disadvantages. In fact, an interesting relief allows you to create an original garden landscape. Ladders are an obligatory element of it.

Materials for the manufacture of steps on a slope

The staircase on the slope of the plot is different from the usual one. It performs the same function - it allows you to go up and down without difficulty. However, its design matters much more than the design of an ordinary mansard or service staircase.

The steps in the garden emphasize the plasticity of the relief. It is very important that their height and width are combined with the characteristics of the landscape. The choice of materials here is made taking into account the design style.

Wood

Not the most suitable material for arranging garden stairs. The wood is very beautiful, easy to process. However, it is unstable to moisture and after a few years it dries up under the influence of rain, begins to rot and mold.

For work in the garden, take hardwood or water-resistant wood. The former include, for example, oak and hornbeam. This is an expensive tree, so it is rarely used as such. Larch is much more affordable, and it only becomes harder from water and frost.

It is pointless to treat garden wooden stairs with varnish, and even more so with paint: the coating does not last long and does not match at all with the garden landscape.

It is often not boards that are used as steps, but sections of the trunks - transverse and longitudinal. Another option is terrace boards. This is a composite of plastic and sawdust, unlike wood, it is much more resistant to water and cold. From terrace boards, stairs are built to verandas and gazebos.

Concrete

A universal option, however, it is used in a not entirely familiar form. Concrete steps obtained by pouring are ugly; such structures are faced with stone or brick. But if you take a concrete stone, the result will be different.

Dyes, decorative particles, like fragments of stone, mica, shells, are added to the concrete mass. Stones are cast in molds, obtaining elements of the most different configuration and type. Concrete stones are laid as decorative ones, trying to make the stairs more picturesque.

Logs

In addition to boards or cuts, a log is also used for arranging stairs in a garden on a slope with their own hands. For this, the trunk of the required width and length is cut in half, receiving steps.

Logs are much lighter than stone, so you can arrange this option alone. It is better to lay wood in its "natural" form - with bark, small knots.

Beam on stones

Combine wood and stone. Initially, each tread is a thick timber formwork. The step is filled with crushed stone and gravel and poured with concrete. After hardening, the formwork is not removed, since this is part of the tread.

Ready-made "boxes" are installed along the slope and each is sewn up with a board made of the same tree. This option is much more resistant to the action of water and frost, since stone is its main component. And since gravel serves as an excellent drainage, moisture does not accumulate here, it goes into the ground. As a result, the wood dries much faster, and the ladder itself lasts much longer.

Stone slabs

The stone fits better than any other material into the garden landscape. They use both ordinary building bricks and any other sufficiently strong: tuff, sandstone, limestone, quartz agglomerate and noble stone, like granite or marble.

The format of the stone depends on the style of the landscape. In well-kept Versailles gardens, stairs are made of granite or hard polished agglomerate. In English gardens, preference is given to the "natural" look: stones of irregular shape, layered, with chips.

Height and width of steps

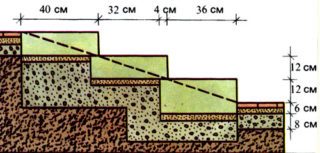

The height and width of the tread is determined by the step of a person of average height. In total, these values should be 50-60 cm. At the same time, stairs with a lower slope are more convenient, since the more gentle the march is, the easier it is to climb it.

The width of the tread should be such that the entire human foot fits. There are no restrictions on the width of the march itself, since such a staircase is, first of all, a decorative structure.

Determine the correct dimensions like this:

- Measure the distance between the upper and lower platforms using a tape measure. Let this distance be 68.2 cm.

- The value is divided by the approximate height of the riser (16 cm) and the number of steps is calculated - 4:28. Round up to 4.

- Divide the distance again by the selected integer and get a riser height of 17 cm.

- Calculate the tread length by subtracting twice the height from the ladder length. Get 34 cm.

- Since the treads are 1 less than the risers, they are corrected by adding 4 step heights and 3 widths. Get a march height of 164 cm.

Theoretical calculations are corrected taking into account the relief. It happens that the space for the steps is not enough, then the length of the tread or the height of the riser is reduced. However, in the end you need to get an integer number of treads of the same size. There may be a deviation of no more than 1 cm for the lowest step.

Required tools and materials

- you always need a hammer and mallet, as well as a shovel and a rake;

- you will need a measuring tool: tape measure, square, level;

- construction mixer for preparing concrete mixture;

- formwork boards, if making a concrete staircase;

- crushed stone and gravel of medium fraction for backfill.

Combined stairs will also require a wooden beam.

Installation instructions

A concrete hillside staircase is the easiest way to build a garden. It is reliable, strong, durable. The only drawback is that it takes at least 4 weeks for the concrete to harden, so the structure will not be ready soon.

- On the slope, the contours of the future staircase are marked with the help of sand or pegs and ropes.

- The top fertile soil layer is removed. Form a slope under the stairs, taking into account that the steps should have a slight outward slope in order to drain rainwater.

- Formwork is assembled from the boards, repeating the contours of all treads. You can take an old tree, but it is important that the upper edges of the planks are even, since the surface of the concrete steps will be leveled along them.

- The formwork is installed according to the marks and upset. The building level is checked for verticality and horizontalness of the structure.

- Tamp the earth at the base of each tread. If the soil is solid, drainage can be dispensed with. If it is loose, a cushion of rubble, gravel or broken brick is laid at the bottom of the trench with a layer of 10 cm.

- The formwork is moistened with water and poured with concrete. The mixture is bayonetted several times with a shovel to prevent voids from appearing. Then the surface of the future step is leveled with a rail.

- The formwork is removed at least one day later, but it is recommended to do this later.

The final setting takes place after 4 weeks. After that, you can start finishing the stairs.

Tips for finishing and decorating steps

A concrete staircase in an area with a slope can be finished with any waterproof material. They are chosen taking into account the peculiarities of the garden landscape:

- Wood - it is better to use not ordinary boards, but terrace boards made of composite material. They will last much longer, and their design is no different from natural wood.

- Natural stone - if it is decided to finish the stairs with such materials as granite, basalt, marble, porcelain stoneware, concrete stairs - the best base for this.

- Tiles - porcelain stoneware or similar in characteristics. The tiles are easy to lay on flat concrete steps.

- Clinker bricks - more suitable for a French or similar style.

Making rungs for a staircase on a slope is not easy. The calculations are difficult: after all, you need to determine the optimal ratio of the length and height of the treads and fit into the dimensions of the slope. No less difficult is the installation and fitting of the finishing material.