Ladders take heavy loads, so they must be strong. In terms of reliability, one of the best materials is metal. A ladder on a metal frame provides strength and safety at the same time. Metal structures are well-deservedly popular, as they fit well into the interior, save space due to smaller supports, and are easy to repair. The frame made of metal structures is easily sheathed with other materials for the architecture of the house, the interior.

- Varieties of stairs on a metal frame

- At the place of installation

- By manufacturing method

- By finishing

- By device principle

- By design features

- By the shape of the frame

- Advantages of stairs on a metal frame

- GOSTs and calculations

- Instructions for making stairs on a metal frame

- Installation of steps and sheathing of the structure

Varieties of stairs on a metal frame

At the place of installation

Stairways can be used permanently or temporarily. Metal stairs to the second floor are classified as follows:

- basic for general use;

- auxiliary - attic, roofing, spare;

- intra-apartment, intra-house - for the movement of people within the boundaries of a house or apartment;

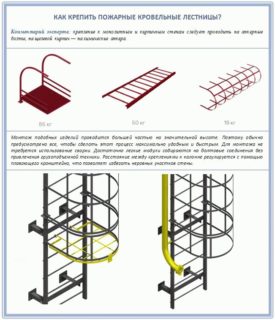

- firefighters;

- ceremonial;

- garden.

Stairways for permanent use are stationary. For temporary use, they can be folded, moved apart, carried.

By manufacturing method

According to the assembly method, there are 2 separate types of staircase frame. Their difference is in the final form:

- Monolithic or open. The construction must be assembled carefully during manufacture. There is no ultimate skin. Careless assembly of the metal frame will lead to the bulkhead of the entire product. The frame can be made without risers using one spine or 2 stringers. After installation, the base is varnished, painted, but there is no further finishing. Such spans must be done after the complete finishing of the premises.

- Modular with a rough frame. The base is made from a channel to reduce cost. The frame is painted when decorating the room. It is better to leave the finishing of steps, fences for later - after the end of the dirty work.

If desired, the frame can be completely hidden. For this, in addition to the steps of the riser, the sidewalls are installed. The kosour will not be visible behind them.

By finishing

The appearance of an iron staircase does not always match the design of the house. For secondary street structures, they leave everything as it is, or they are finished with materials that are not afraid of precipitation and frost. From the inside, a beautiful finish with a combination of practical and decorative functions is important.

The metal frame is sheathed with any one material or a combined finish is made from 2 or more materials. In the budget version, the kosoura are simply painted.

The tree is allowed to be used for steps, risers. As fences - metal elements, glass, drywall. Laminate cladding outside is a budget option.

For stairs without kosour or forged, external finishing is optional.

By device principle

All stairs are divided into 2 large subtypes: with and without stringers. The frame of the staircase often looks like a load-bearing beam on which the entire structure rests.

Frameless structures include structures, the steps of which are not tied to the load-bearing beam. They are mounted on bolts, studs. The other side is attached to the wall using the same screws.Part can be attached to the wall stringer. Such designs look light, airy. In terms of bearing capacity, they are not inferior to stringer options.

According to the construction of the stairs there are:

- Screw. These are steps spiraling upward. Such structures are needed in rooms where there is little space. A striking example is the rise in the narrow towers of the palaces. The screw is spiral, broken, with several platforms. The design is supported by stringers and bolts.

- Spiral and screw designs may differ. The screw can lie on the stringers. The spiral is attached to the support post. The steps are, as it were, strung on it and are arranged in a fan. The top of the post is often attached to the ceiling.

- Pain relief. In such devices, stringers are not used. The ladder is supported by a separate frame. The entire weight of the structure is transferred to the walls and ceiling.

- Marching. The most simple, common models. The power element is stringers in closed models, or bowstrings in open ones.

By design features

Despite the variety of ladders on a metal frame, their basic set is similar.

- Steps. Horizontal surfaces that a person steps on when going up or down.

- Kosoura, bowstrings. Supporting steps of the structure, located on the sides.

- Fencing. These are handrails, balusters, handrails, posts along the adjacent wall and protecting a person from falling.

- Beams, columns, bolts. Refers to vertical supports.

The main options for the supporting frame:

- on kosoura, the steps are supported by 1-3 beams at the same time;

- when placed on bowstrings, the ends of the treads are fixed on the sidewalls of the crossbars;

- on the bolts, the frame is assembled from elements where the steps and railings are connected with special bolts;

- cable structures;

- cantilever mounted to the wall.

For the movement of small children, the distance between the posts, balusters should not exceed 15 cm.

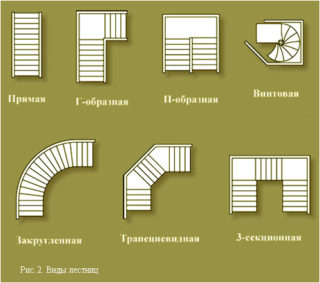

By the shape of the frame

- Straight. A primitive lifting option. No twists and turns. Takes up a lot of space.

- Two-level with a march division by a platform. The ladder sections are positioned at 90 degrees to each other.

- U-shaped. A difficult option with parallel flights. A span is made in the middle - a storey area or an inter-storey area. As an example - marches in multi-storey buildings.

- Rounded. The design resembles a screw, but the direction of the exit coincides with the direction of the entrance.

- Three-section. A difficult option with combining two L-shaped stairs.

- Trapezoidal. This is an unusual option. He has no restrictions on the angles between marches. The exclusive model is suitable for designer interiors, non-standard objects. Adapted to different options for rooms, levels.

Rooms with irregular shapes require a special approach. They combine different classes of climbs.

Advantages of stairs on a metal frame

Iron stairs have a lot of advantages:

- The metal frame is more durable, stronger than wood.

- Metal-frame steps, beams do not creak.

- Easily adapt to any architecture, interior.

- They have increased maintainability.

The tree dries up over time - cracks appear, burst surfaces, rot. The old staircase will not break underfoot, but it will lose its former aesthetics, it will begin to creak and stagger. The changes will only increase, given the softness of the material. There are top specimens of beech, oak and other hardwoods, timeless. But making them by an experienced craftsman is very expensive. Metal stairs are more resistant to temporary changes. Its price will be lower than oak, beech, ash.

Squeaks are a frequent companion for residents of multi-level wooden houses and apartments. The easiest way to avoid this phenomenon is to make a staircase to the second floor on a metal frame in a private house. The creak is the result of joining wooden structures. Under dynamic load, the elements of the stairs begin to move, rub against each other.Steps, stringers, balusters, and other conjugations can creak. Sometimes it is not easy to find the place of the creak and fix the problem. The metal structure is free from this disadvantage. The tree does not come into contact with the tree; plastic dowels or special soft gaskets are installed at the joints.

The iron structure will fit into both classics and high-tech. There are a lot of options for making the frame: steel bowstrings, modular frame, straight, broken kosour. You can give absolutely any look. The design is painted in any color. Railings are installed from any material - wood, stainless steel, forging, interior.

The increased maintainability of the metal frame is associated with a simple replacement of the attachment point or element. This is almost always enough. Wooden structures do not always change element by element. If the supporting bowstring is broken, dismantling of the entire structure is inevitable. A metal bowstring is difficult to break and easily reinforced in a weak spot.

GOSTs and calculations

GOST 2312078 is applicable to stairs, fences, platforms with an operating temperature of at least -65 degrees. General requirements of the standard:

- The inclination of the flight of stairs is 45-60 degrees.

- Ladders and their elements must withstand a short-term load of 200-400 kg / cm².

- The height of the march with a slope of 45 degrees - up to 4.2 m, with a slope of 60 degrees - 6 m.

- With a smaller slope, the steps are wider - 50, 70, 90 cm at 45 degrees; 50, 70 cm - at 60 degrees.

- The height of the fence varies from 1 to 1.2 m.

- The decks with this GOST are perforated, lattice stamped, solid with corrugation, welded from a round bar, from vertical parallel strips.

- The structure should not have sharp corners, edges.

- The slope of the steps after installation is no more than 1 degree.

- The connection between the platform and the span is only welded.

- The depth of the approach is at least 25 cm with a width of 90 cm, with a fence height of more than 1.2 m.

- Marching structures are mounted at heights of more than 20 m; up to this height, vertical elements are possible.

- The distance between closely spaced spans is more than 75 cm.

Separate requirement for vertical flights:

- The lower span is allowed to be made retractable.

- Destruction of walls at fastening points is not allowed.

- The minimum permissible load in the center of the march is 180 kgf.

- The minimum permissible horizontal load on the railing is 54 kgf, the distance between the steps is up to 35 cm, from the bowstring to the wall is 30 centimeters or more.

- The height from the bottom step to the ground is up to 1.5 m.

- The minimum width of a staircase without a guardrail is 60 cm, with a handrail 80 cm or more.

- Strength testing takes place at the time of commissioning and in the future - at least once every 5 years.

GOST 25772 83 summarizes regulatory documents and puts forward general requirements:

- Requirements for the load of fences - 40 kgf in all directions with a deflection of no more than 5 cm.

- Coating of supports with anti-slip materials.

- The distance from the left to the right bowstring is 40-80 cm.

- Step step 30-34 cm.

- The height between the ground and the first step is no more than 40 cm.

- For ladders with a height of more than 5 m and a slope of 75 degrees, an arc fence and a structure for attaching a safety belt are required.

- The step of the arc fence is not more than 80 cm, with at least 3 guides attached to each other. The distance between the march and the arcs is 70-80 cm.

- Testing the structure at least once a year, exceeding the standard load by 20%.

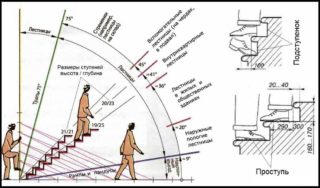

The calculation of mid-flight stairs is based on the design, slope angle, width, and depth of steps.

- The optimal step width is considered to be 30 cm. This value is ideal for a person's step and will not allow him to get lost. Attic stairs, auxiliary ones may have a smaller step width.

- The minimum clearance is 2 m.

- Step height no more than 20 cm.

- The optimum width is about 1 m.Reducing is not recommended, as it makes it difficult for 2 people to pass.

The project starts with placement and style selection. After that, a detailed drawing is made, materials for cladding are selected. It is important to measure the distance from the floor of the first floor to the floor of the second. If there is no floor covering, screed, their thickness is taken into account.

Instructions for making stairs on a metal frame

A metal staircase, when made by hand, sometimes squeezes into the space provided with difficulty. Therefore, it is initially important to create an accurate project, drawing. Step-by-step instruction:

- Carry out the actual measurement of the opening - width on a clean floor, height.

- Remove the size of openings, doors, windows, so as not to block them with a metal frame.

- After sketching on paper, you should transfer the calculation of the drawing of a metal staircase to the program for modeling volumetric objects.

- Find out the height from the floor of the 1st floor to the floor of the 2nd floor. Determine the number of comfortable steps to climb. The calculation of the dimensions of the steps at a certain angle of inclination can be found in the tables on the Internet, online calculators.

- Avoid the production of winders during the design phase. Draw a 3D model. This stage can be given to the design organization for revision.

- Make sure that the constructed models do not interfere with the opening of doors and windows. Materials and fasteners should be taken with a margin of 5-10% and stored in a dry room. Draw the metal frame:

- Select the type of stringer. A 12P channel or a pipe of at least 100 * 100 mm is often used. For steps - an angle of 35-50 mm. Racks to the floor - pipe 80 * 80 mm. The kosour adjacent to the wall can be made less durable if it is possible to anchor into the wall.

- Treads and risers made of wood, concrete, marble, laminate are mounted on the frame. It is allowed to leave all-metal or lattice steps.

- Parts are sequentially welded, sheathed, painted.

Broken shapes require high precision. But in this case, there is little metal waste.

In prefabricated stairs of the latest generations, the height of the steps, the angles of rotation may vary. They are mounted on bolts. Mounts do not loosen, do not require tightening for a long time.

Installation of steps and sheathing of the structure

After finishing the stairs with wood, a complete illusion of a solid wood structure is obtained. Wood is tinted, tinted, varnished, waxed.

An alternative to wood is laminate boarding. Fiber board is cheaper. It is fixed on a plywood base. High-quality laminate is resistant to damage and durable.

Ceramic, clinker tiles are used to decorate the frame of the staircase made of metal inside the house and outdoor structures. They are resistant to precipitation, not afraid of dirt, frost, heat. Shoes with hard soles and heels are also not harmful. For the street, it is additionally covered with anti-slip coatings.

For outdoor and indoor marches, a terrace board is used. The material is not afraid of moisture, well drilled, cut, glued.

Finishing with marble, mosaic looks spectacular. Natural marble can be replaced with cement-based artificial marble.

The metal structure can even withstand monolith concrete steps or prefabricated ones.

The fence is made in the form:

- openwork lattices;

- metal pipes, rods;

- polyurethane, wooden figured balusters, plastic panels;

- glass inserts.

Combined types of cladding look unusual and interesting. In this case, the staircase becomes a functional element of the house and part of the interior.