Ladders in a private house to the second floor are ordered from specialists or made independently. It is necessary to study the variety of designs and options for using building materials in order to do the work with your own hands or control the builders.

General design requirements

When choosing a staircase option, take into account the requirements:

- safety - protection against falling and slipping;

- minimum noise level - no squeak and shock during use;

- ergonomics - tread width and riser height;

- manufacturability in self-production;

- final cost;

- durability.

An important factor is the appearance of the structure, its combination with the general design solutions of the house.

Types of stairs

The variety of designs is grouped according to several criteria:

- geometric shape;

- material of manufacture;

- type of attachment.

When designing, all indicators in the complex are taken into account, taking into account the materials from which the walls and floors are built.

Stair shape

Based on the size of the house and the type of flooring, available free space, spiral, mid-flight and combined staircases are chosen.

Screw The (spiral) type is used when the space of the room is limited in order to save usable space. The staircase rises in a spiral. The option looks impressive, but the design has several disadvantages:

- the difficulty of independent construction, high requirements for the qualifications and experience of the master;

- use for the manufacture of special expensive tools;

- low ergonomics due to narrow steps and the constant need to climb (descend) in a spiral;

- problems when moving large items between floors due to the screw structure.

Marching a staircase to the second floor, built with your own hands, is the most popular type. It is distinguished by:

- simplicity of design;

- uniformity of all elements that are made of the same size, which contributes to simplicity (manufacturability) during manufacture and installation;

- simplicity of the scheme and calculation of the flight of stairs;

- suitability for the construction of any type of materials;

- ease of use, including for moving pieces of furniture;

- the presence of platforms that allow you to make turns at different angles, more efficiently using the space of the house.

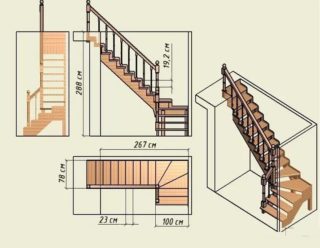

Marching stairs are built with one, two or multi-span. Between the spans, platforms are arranged - turning or straight. This design helps to make the ladder optimal in terms of the angle of rise.

Among all the options, a straight flight staircase takes up the most usable area of the house. In order to save money, the slope angle is increased, but this affects safety and ergonomics.

Combined version contains parts of spiral and mid-flight staircases. It is not easy to make a wooden staircase of the combined type with your own hands; experience in this kind of work is required.

Step installation methods

The most common are several options for mounting steps:

- on bowstrings;

- using kosour;

- boltsevoe.

The method of installation depends on the building material used, the layout of the house and the adopted architectural and design design of the premises.

Ladder on bowstrings

The steps to the beam are attached in different ways:

- With mortise or retractable steps. In the beam, grooves are selected where structural elements are inserted. The main condition is to accurately determine the dimensions and make the grooves on both bowstrings in the same way.

- To the corners. Angles or bars are attached to the beams, which serve as the basis for the steps.

- Winder steps - a variant of the design of spiral staircases. A string for steps is attached to the wall of the house, and the second part is mounted on a support post.

- On pads, which serve as a support for steps and risers.

As a rule, bowstring designs are closed.

Outwardly, the ladder on bowstrings looks massive, but at the same time has increased strength.

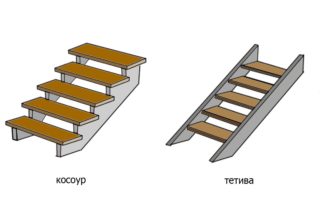

Kosoura

Unlike a bowstring, a stringer beam has a serrated shape. The steps rest on the cutouts. When viewed from the side, their ends are visible.

There can be one, two or several toothed beams. The first option is preferable for lightweight ladders with little load.

Two kosour - the most common option, when the staircase is made by hand and has one turn.

For complex options, 3 or more stringers can be used, for example, in places of turns or with a large width of steps.

Boltsy

Boltsy is the German word for bolt.

Boltz ladders have gained popularity recently. A design feature is the absence of bowstrings, stringers and risers.

The steps are attached to the wall on one side, and on the other they lean on each other and are suspended from the railing.

Despite the outwardly fragile appearance, the structure is capable of withstanding several quintals of load.

Materials for making

You can assemble a ladder from a variety of materials.

- Wood. The cheapest option, suitable for stairs of any design. The material is easy to process, the boards are easy to replace when aging. To build a staircase from wood, you need a minimum of tools. Factory-processed step blanks are sold in any hardware store.

- Metal is an almost eternal material that can be easily combined with wood, glass, plastic. Structures made of it are durable, easy to paint. The disadvantage is noise during use.

- Glass is used as a building envelope. Combined with metal balusters, it gives the staircase a modern look. Glass is a shock hazard, especially at the end - protective pads must be fitted.

- Concrete is a durable material, the steps never loosen. During installation, it is laborious. Distinguish between monolithic cast and prefabricated structures, in which the steps are attached to the frame during construction. Natural or artificial stone, imitation of a rock, are often used for decoration.

When choosing a material, take into account the bearing capacity of the walls and floors of the first and second floors of the building.

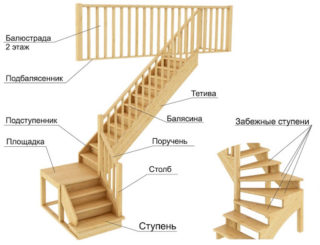

Design features

The chosen staircase design must combine safety and usability. GOSTs and Codes of Rules set the parameters of structural elements.

It is prohibited to use transformable (folding, sliding, etc.) stairs as the main ones. Such structures are used to access basements and attics.

General requirements:

- the minimum width of stairs for two-story residential buildings is 800 mm, for buildings higher - at least 1000 mm;

- the width of the march should be the same throughout the height;

- the number of steps in the march is from 3 to 18, it is desirable that their number be odd;

- the maximum slope should not exceed 50 °, the minimum cannot be less than 20 °.

The dimensions of the steps are chosen based on the maximum consideration of ergonomics:

- within one march, the height of the steps is selected within 12–20 cm, and the difference between them is no more than 5 mm;

- the width of the steps on the main interfloor staircases is at least 250 mm, with a width greater than 26 cm, the size of the protrusion is chosen no more than 300 mm;

- for wedge-shaped versions, the minimum tread width in the working area must be at least 100 mm.

The length of the landings is selected between 130-145 cm.

The minimum height of the railing is 90 cm, and the distance between the balusters is not less than 150 m.

Before designing, the distance between the coatings of the first and second floors, as well as the parameters of the interfloor opening, are accurately measured. Take into account the thickness of the floor finish.

Taking into account the interfloor distances and the requirements for the height and width of the steps, their total number can be calculated. Based on the measurement results, a diagram or drawing is prepared.

Step-by-step instructions for assembling a ladder on bowstrings

The first step is to measure the height of the first floor and the opening of the ceiling.

If there is not enough space, you can make a staircase to the second floor with an intermediate turning platform.

For work you will need:

- hacksaw for wood;

- level, plumb;

- marking cord, tape measure;

- chisel, hammer;

- a set of screwdrivers or a screwdriver with bits;

- a hammer drill or hammer drill if the walls in the house are brick;

- plane.

If there are no woodworking skills, they acquire ready-made steps, bowstring boards and risers.

For fasteners, you will need self-tapping screws, dowels, an anchor, depending on the chosen option for fastening the stringers to the wall and steps to the stringers.

Finishing is done with a stain of the selected shade, colored or colorless varnish, paint.

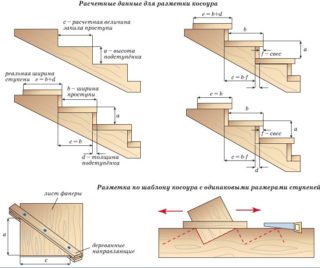

The next stage is marking the stringer. Using the data of preliminary calculations, the cuts are marked with a construction pencil. After marking, it is convenient to assess the correctness of the calculations and make adjustments before starting the cut. It is convenient to mark the second kosour after the first is made.

The next stage is installation and strong fastening of the stringers. The element is attached to a wooden wall using 100x6 mm screws with a head for a wrench or hexagon. In order to further hide the fasteners, a hole of a larger diameter is drilled to the depth of the head, and the screw head is screwed in flush with the surface of the board.

Focusing on the level of the wall part, the second stringer is installed. Support pillars are used on rotary ladders.

The next step is sizing, installation of steps and risers. Parts are cut with a hacksaw with fine teeth or a jigsaw with a set minimum saw swing. Irregularities of the cuts are sanded with sandpaper.

The easiest way is to drill the steps and fix them with powerful self-tapping screws.

To give a beautiful appearance to the stairs, self-tapping screws with decorative heads are used, which are twisted in a secret. Another way to hide the fasteners is to drill a larger hole where the head is completely hidden.

The final finishing is carried out with plastic or wood plugs. Parts are purchased in building materials stores, where you can choose products of various shapes, textures and colors.

The second method of fastening is the use of dowels, planted with wood glue.

For wide stairs with frequent movement of people, it is better not to use dowels - over time, the boards will loosen and will emit an unpleasant creak.

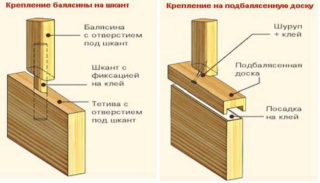

There are several ways:

- Fastening to the side edge. A hole is drilled and 2 powerful self-tapping screws are screwed in.

- Using a balancing board, which is an overlay piece with a groove on the bottom. The baluster is filed according to the slope angle of the stairs and screwed to the bottom of the baluster. Next, the connected parts are attached to the string.

- Fastening with dowels. A hole for the tongue is drilled in the steps and baluster. With the help of glue, the parts are connected to each other.

The top of the balusters is connected with handrails using self-tapping screws or dowels. To hide the fasteners, decorative overlays are attached over the balusters.

Finish the installation of the stairs with a decorative finish: painting or varnishing.