A variety of roofing materials allows you to choose an option that will provide your home with reliable protection and an attractive architectural appearance. It remains to choose the best material for the roof of a private house, keeping within the estimate and not regretting the consequences. There is only one advice - to carefully study the characteristics of the products, their advantages and disadvantages.

Parameters for the selection of roofing material

The roof determines the architectural appearance of the house and affects the durability of its operation. When choosing a roofing material, take into account its main characteristics:

- Durability - the service life of building materials for the roof is from 10 to 100 years. Products that are not subject to wear are more expensive, but in the end they pay off.

- The weight of the roof covering is an important parameter when calculating the load on the rafter system. Lightweight materials can be installed if climatic conditions permit. They are permissible in regions with low snow and wind loads.

- Moisture resistance - moisture resistance and high-quality waterproofing are significant characteristics for home use.

- Frost resistance - the material must retain its properties when exposed to low negative temperatures.

- Insulating properties - a coating with low thermal conductivity and good noise insulation characteristics is preferable. For other types of roofing, reliable insulation and sound insulation will be required.

- Safety is a complex of several factors: flammability of products, environmental friendliness, the possibility of avalanches and lightning strikes.

- Aesthetics - the roof should correspond to the general architectural style, harmoniously look with the facade of the house and outbuildings.

Cost is one of the parameters that determines the choice of coverage. You should take into account the price of products, additional elements, fasteners, lathing. The features of the installation of the roofing also affect the final estimate. Laying sheet products will be cheaper than piece ones.

Roof covering materials and their technical characteristics

When choosing which roof is better to make on a low-rise building, they consider sheet, roll and piece materials.

Metal tile

Roofing sheets are made from steel, aluminum or copper. The wavy profile of the products imitates natural tiles. The sheets have a multi-layer coating, which includes a primer, galvanized, polymer and protective varnish. In terms of the architectural appearance of the roof, the material can be compared to ceramic tiles. The permissible slope during installation is 15 °, but a coating less than 20 ° requires additional sealing of the joints. To fix the sheets, self-tapping screws with rubber gaskets are required so as not to damage the polymer layer.

Advantages:

- durability 30-50 years;

- light weight;

- ease of installation;

- fire resistance;

- attractive look.

Disadvantages:

- a large amount of waste;

- noisiness;

- high thermal conductivity.

Metal tiles can be installed over old roofs. Installation is simple, quick and inexpensive. The minimum slope of the slope is from 12 °.The price of products depends on the type of polymer coating, the budget option for processing is acrylic, the more expensive and reliable is pural.

Ceramic roof tiles

Clay shingles are one of the oldest roofing materials. Modern products are produced in various shapes and wave heights, but the high quality remains unchanged.

Advantages:

- strength and durability, service life 150 years;

- excellent heat and sound insulation;

- color fastness to fading;

- environmental friendliness;

- frost resistance;

- respectable look.

Disadvantages:

- significant weight, the weight of the tiles is 40-60 kg / sq. m;

- high cost - $ 20-50 per sq. m;

- fragility of products.

A shingle roof requires cleaning of lichen, which over time grows on uneven surfaces. With proper installation, repairs will be required in 15-20 years.

Ondulin

Inexpensive material that is in demand in private construction. Outwardly, it looks like slate, but differs in manufacturing technology. Corrugated sheets are made from pressed cellulose covered with quality bitumen and a layer of quartz sand. Coloring pigments are used to give different shades. The large sheet area (200 × 96 cm) allows for quick roof installation.

Advantages:

- moisture resistance;

- frost resistance;

- environmental Safety;

- low price;

- heat and sound insulation;

- light weight.

Disadvantages:

- subject to burning;

- fragile, do not step on when laying;

- the color fades.

Ondulin can be installed on a roof with a slight slope - from 6 °, but in this case, a continuous lathing and an overlap of adjacent sheets of 30 cm for steeper structures, a frame from a bar is made in increments of 45-60 cm.As a fastener, special nails of the same manufacturer are required ...

Slate

Asbestos-cement slate is a practical and cheap material. It is cheaper than corrugated board, they cover the roofs of houses, outbuildings, production workshops. Sheets are flat and wavy. The second option is stronger due to stiffening ribs. In private construction, 8-wave sheets are popular. The weight of the material depends on the dimensions, its thickness ranges from 8 to 10 mm.

Advantages:

- low thermal conductivity;

- long service life;

- incombustibility;

- low noise;

- ease of processing;

- low cost.

Disadvantages:

- the presence of harmful asbestos in the composition of the material;

- the sheets are overgrown with moss and require cleaning;

- significant weight.

When calculating the required amount of material, the working size of the slate is taken into account, because the sheets are overlapped. Coating the roof with polymer paint improves the appearance, increases the service life and prevents the appearance of vegetation on the material.

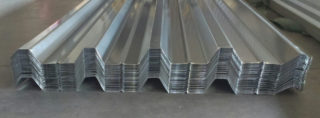

Corrugated board

Steel sheets with a corrugated, trapezoidal or square profile that enhances the rigidity of products. For protection from external influences, they are galvanized, then painted or covered with a layer of polymers. On the roof are products marked "N", "NS", "PC",

Advantages:

- resistance to corrosion and moisture;

- light weight;

- long service life, in fact, up to 50 years;

- fire safety;

- affordable cost;

- versatility;

- ease of installation.

Disadvantages:

- noisiness;

- high thermal conductivity;

- the complexity of cutting.

Galvanized steel sheet is cheap, but has an unpresentable look. They are used to cover the outbuildings. Sheets with a decorative protective layer are recommended for roofing in private houses.

Flexible roof

Soft roofing or flexible shingles are piece and roll products based on glass fiber or fiberglass. The base is impregnated with bitumen and sprinkled with stone chips.The mineral component protects against ultraviolet radiation and gives volume. Products are produced in the form of tiles of various shapes and colors. An adhesive layer for installation is applied on the inside. With a slope of 25 °, the material can be fixed with nails.

Advantages:

- possibility of installation on a curved roof;

- economical consumption;

- moisture resistance;

- noise absorption;

- resistance to temperature fluctuations;

- a wide range of shades and shapes.

Disadvantages:

- low fire safety;

- high price;

- the need for a solid base and good ventilation.

The reliability of the coating operation depends on the quality of the installation of the shingles. The material is laid on a solid plywood or chipboard crate. The coating is recommended for complex roofs.

Roll welded roofing

This group includes materials based on fiberglass or polyester impregnated with bitumen. The surface is treated with a protective layer of dolomite, talc, shale and other crushed minerals. Products are classified according to the base material, which ensures reliable operation. Polyester has the best technical characteristics, but it is more expensive than other products. The shortest service life and the price of roofing material.

Advantages:

- reliable waterproofing;

- light weight;

- affordable cost;

- elasticity.

Disadvantages:

- flammability;

- use when laying open fire;

- short service life of some varieties.

The welded roof is used for flat and pitched roofs. A solid base is mounted under it. During operation, the roof should not be subjected to stress.

Rules for choosing material for roof construction

By design, roofs are divided into two main types: flat (slope angle up to 12 °) and pitched. The first option is not common; it is suitable for regions with a mild climate and little rainfall. Pitched roofs are presented in a wide variety of designs: single-pitched, double-pitched, four-pitched (hip, hip).

Material consumption depends on the design. Roofs of complex shape have many transitions, slopes of various slopes, valleys. When installing sheet materials, trimming is performed, so more than 30% goes to waste. In such a situation, a practical option is a soft roof or piece materials - various types of tiles. Metal tiles, profiled sheets, ondulin or slate are recommended for single-pitch and gable roofs.

The importance of soundproofing devices

To cover the roof of the future house, many choose profiled sheets, metal tiles and other options for metal roofing. The materials are practical, safe, affordable and durable. Their disadvantage is the high noise level during rain. So that the knock of drops does not violate comfort, it is necessary to take care of sound insulation when installing a roofing cake.

Mineral wool is recommended as a material for sound insulation. It has a fibrous structure that perfectly absorbs sound waves. Also, the material is a heater, therefore it performs two functions at once. Any mineral wool is suitable - glass, slag, basalt.

Step-by-step installation instructions:

- A waterproofing sheet (membrane, polyethylene film) is attached to the rafters.

- A crate is stuffed from a bar equal to the thickness of the mineral wool slabs.

- Soundproofing material is tightly placed between the slats.

- Next, a counter lathing from a bar is stuffed, along which we cover the roof with a profiled sheet or metal tile.

If the roof has already been installed, soundproofing is performed from the inside of the attic. Plates of mineral wool are placed between the rafters, covered with a vapor barrier film. It remains to complete finishing work.

The choice of roofing material occurs at the design stage of the house.This makes it possible to take into account the load of the roof on the base and the supporting structures. Carefully study the technical characteristics of the products and the installation features. Price also plays an important role, but there are quite attractive and affordable materials on the building materials market.

Insulation is needed for houses with a defective second floor, and if the second floor has normal walls, a cold attic and a gable roof, metal tiles - a roof without problems and at minimal cost.