Mauerlat for a gable roof helps to firmly fix it and evenly distribute the load. You should understand its structure and decide on the materials, construction technology, so that the element will serve for a long time.

Necessity and purpose

Mauerlat is the base of the roof structure. An element performs a number of different tasks at the same time:

- The role of the base for the installation of rafters. The Mauerlat mount helps to combine them into a single system.

- Distribution of the load that the walls have to bear. Mauerlats help to increase the area of influence of each element. This eliminates the non-uniformity in the distribution of forces created by snow and wind.

- Compensation for the expansion of the rafters.

- Connecting the roof frame to wall structures. The Mauerlat device creates a stable connection between the roof and the rest of the building. Thanks to this, even powerful wind gusts will not break it.

It is necessary to figure out whether it is possible to build a roof without a Mauerlat and for what types of buildings there is a need for it. If we are talking about a frame or lightweight wooden house, this structural unit can be ignored. There, its functions are performed by bars or the final crown. If the roof is made of metal, the upper transverse beam, made of a channel or high-strength pipe, is responsible for the tasks under consideration.

If the building is made of block materials, and the roof is planned from wood, the installation of a Mauerlat is necessary. It is also recommended for the arrangement of the attic.

Mauerlat device

The Mauerlat timber must be of sufficient strength, not have crevices, cracks and other violations of integrity, necrosis and knotty. You can also make a structure from thick boards. Lumber from coniferous trees, such as pine or larch, is commonly used. They are lightweight, durable and shrink little when dry. Sometimes round timber is used, from which the bark is thoroughly cleaned. In this case, one of the sides must be cut off on a circular machine to create close contact with the wall surface.

In order for the structure to be reliable, unnecessary moisture must be removed from the lumber. A drying chamber is well suited for this purpose.

Raw materials must be treated with antiseptic and fire-fighting impregnations. It's good if you can get a combined composition that combines the effects of both types.

Sometimes it is recommended to make a structure from sawn timber, the harvesting of which was carried out in the winter.

Section calculation

Excessive thickness of the elements is not the best option: in this case, an increased load on the building arises, and installation work becomes more difficult.

When calculating the cross-section of the Mauerlat, they are often guided by the diameter of the outer walls. The thickness of the components of the structure to be erected must be at least one third of this value. The standard dimensions of the bars are from 0.15x0.08 m to 0.2x0.2 m.

When installing the Mauerlat, the connection of boards is sometimes used.This helps to save on resources, but such a solution is suitable only when the load on the structure is low.

Mauerlat building solutions

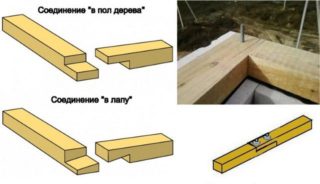

To combine the fragments, their end parts are sawn to half the thickness and coated with an antiseptic compound. Special plates, anchors or nails can act as fasteners. Sometimes everything is furnished so that the connection falls on the mortgage pin. This option provides the most robust design.

To connect the transverse elements at the corners, a dowel is hammered into the hole made by the drill. At the same time, the end parts of the beams are fastened with staples driven obliquely. This makes the structure more rigid.

Mounting methods

To aerated concrete

Aerated concrete is a fragile material, so you should not use anchors or dowels for it. In this case, cracks can easily appear in the anchorage areas. For such blocks, chemical anchoring elements are better suited. In the wall thickness, they are held by quickly hardening glue. To install such fasteners, a truncated conical recess is drilled in the block. Having cleaned its inside, a threaded rod is placed there. Then the glue is poured. When it grabs, the beams are fastened to the studs.

To the brick wall

Another method involves the use of staples. In this case, a block plug is laid several rows below the top. This is done with the end facing outward. One of the ends of the bracket is hammered into the beam, the other into the cork. The beam must be thicker than the length of the shortened side of the fastener. The size of the bracket is selected to be identical to the distance between the plug and the beam.

Installing Mauerlat

There are a number of rules that must be followed when installing this configuration:

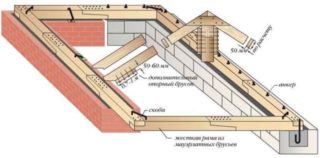

- Installation is carried out on the inside of the main wall.

- You need to take care of the evenness of the top of the masonry. It should be checked horizontally.

- It is better to choose bars or boards with a cross-section in the shape of a quadrangle, and not a circle, since in a firmly made structure, the lower regions of these elements are in close contact with the armored belt or the top of the masonry.

- The distance from the outer wall edge to the support bar must be at least 50 mm.

- It is necessary to take care of the internal insulation of the supporting structure.The same thermal insulation materials are used for the outer wall as for the walls of the building.

It is best to fasten the Mauerlat elements with an oblique cut. In this case, the configuration becomes particularly rigid with vertically directed forces.

Another way of combining components is "in a half-tree" with a straight or oblique lock. Different products can act as fasteners. The most common connection is with bolts. Massive screws and ordinary nails are also used.

Underlay and waterproofing applications

When the wall is in contact with the Mauerlat structure, substances that differ in their ability to conduct heat come into contact. Because of this, condensed moisture accumulates in these areas. Contact with water leads to wood rotting, therefore it is extremely important to equip waterproofing, cutting off lumber from structures that differ from them in terms of performance.

The most common means for this purpose are roofing felt and roll products containing bitumen. They are always laid out in a couple of layers. Roofing material can be rolled out on a wall plane or fastened to a timber structure. In the second case, the strip of the required dimensions is marked and separated from the roll using a hacksaw, and a stapler and staples are used to fix it.

On top of the waterproofing layer, a linen and jute inter-row seal is sometimes laid. The Mauerlat can also be mounted on a polyethylene foam pad. This material copes well with insulation and waterproofing. Another trick to protect the timber from rotting is to treat it with liquid rubber.