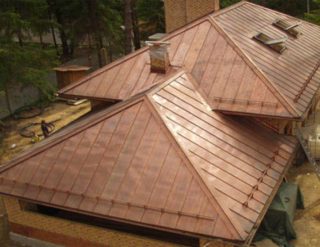

Copper roofing has a long history of use in private and industrial construction. It began to be used when humanity learned to mine and process this metal. The attitude to such a flooring is ambiguous in terms of practicality and cost. However, a copper roof is a sign of good taste, wealth and foresight for a property owner. Modern industry offers users a wide range of piece and roll-type products that have undergone various forms of chemical and mechanical processing. The material has become as accessible as possible to private developers and has been adapted for various finishing methods.

Material characteristics

Roofing copper immediately after leaving the conveyor has a yellow color with a slight reddish tint. The surface is smooth and shiny, the sheets are easily bent even by hand, without the use of tools. Over time, due to susceptibility to oxidation, the copper coating of the roof darkens, gradually becoming dull, brown, green and black. However, oxidation is superficial, it does not turn into deep corrosion, thanks to which a copper roof can last up to 200 years without maintenance and repair.

Main characteristics and cost of the material:

- type - non-ferrous metal;

- specific gravity - 8.7 g / cm³;

- operating temperature range - from -80 ºС to +150 ºС;

- sheet price - 4000-8000 rubles / m²;

- the price of checkers, tiles - 8000-12000 rubles / m².

If you hire a master, the cost of installing a folded roof will be from 1000 rubles / m². Installation of a copper roof from a piece covering will cost less - from 500 rubles / m².

Varieties of copper

The following types of copper are used to create roofing:

- Classic. It is a raw material without any additives. No surface treatment is carried out, no protective layers are applied. Darkening occurs naturally. In the first year, the color changes to red, then after 3-4 years it turns brown, then after another 10 years it turns green.

- Oxidized. After rolling or stamping, the products are treated with solutions of sodium hydroxide, potassium persulfate or ammonia. As a result, a black, green or blue protective film is formed on the metal. The preforms can be oxidized in whole or in parts to create images of a certain content on them.

- Patinated. Otherwise, you can call such copper artificially aged. The technology is used to create a coating that looks like it has served for decades. To achieve the patina, the metal is treated with a sulfuric solution, which forms a sulphide layer on its surface, which has a characteristic dark green color, close to malachite.

The price of the processed material can be 30-50% higher than the classic one. You can save money by self-oxidizing or patinating copper before installing the coating.

Types of copper tile roofs

For roof cladding, the following types of coating can be used:

- Checker. They are stamped plates with locks at the top and bottom. The shape of checkers can be square, trapezoidal, diamond-shaped, hexagonal. To enhance the design of the tiles, embossing, embossing and etching are used. The assembly is carried out using latches and rivets, due to which the solidity and tightness of the flooring is achieved. Copper tiles are laid on slopes with a slope of 35º or more. The base is a wooden lathing with a step corresponding to the details of the coating.

- Scales. A copper roof consists of many plates that are either cut by hand or purchased off-the-shelf. The edges of the plates are bent in such a way that they form a joint joint with adjacent fragments. Scale-shaped flooring is presentable and practical, and its repair does not cause any particular difficulties. It is excellent for finishing difficult curved surfaces.

When choosing a material, one should take into account the design of nearby buildings and the features of landscape design.

Types of seam copper roofing

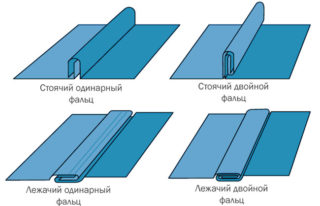

Installation of a copper roof can be carried out using the following types of lock connections:

- Single. The simplest and fastest way to connect strips. In this case, it is produced like a thorn-groove system. In the absence of tightness and a high level of snow, there is a risk of leaks.

- Double. Here, the edges of the strips are wrapped 180 degrees, due to which complete protection of the roof from water is achieved. Such a connection is more labor-consuming to implement, but has better performance characteristics.

Depending on the priorities of the property owners, a standing or recumbent version of the castle is chosen.

Advantages and disadvantages of copper roofing

Like any engineering structure, a copper roof has its pros and cons. They must be taken into account before choosing this technology.

The advantages are as follows:

- Long service life. Even if the building is to be demolished, the metal can be removed, reused, or profitably recycled.

- Ecological cleanliness. Copper does not emit harmful substances, mold does not develop on the surface of the flooring. The material does not rot or rust.

- Presentable appearance. It is preserved at all stages of operation, passing over time into new qualities. The metal changes color and texture, but remains attractive.

- Flexibility and ductility. The ability to use strips and tiles for finishing structures of any, even very complex configuration. This also applies to locks, which are faster and easier to make than on galvanized steel.

- Maintainability. If the ramp is broken, its recovery will not take long. A patch is applied, tinning and rapid artificial aging is carried out. There will be no traces of work.

- Applicability to any roof system. Tiles and rolls fit equally well on slatted and solid sheathing. No frame reinforcement is required.

The copper construction also has disadvantages:

- High price. Consists of the price of the metal, its processing, molding and laying on the roof frame. However, if you divide the amount by the service life, take into account the absence of the need for maintenance and repair, the result will not be in favor of cheaper coatings.

- The characteristic shine in the sun, which lasts for the first year, until the coating begins to darken and becomes matte. This kind of shine may not be to the liking of property owners and their neighbors.

- Good thermal conductivity. In the sun, the flooring becomes very hot, transferring heat through the floor slab to the rooms below it. You will need high-quality insulation that is not susceptible to high temperatures. You can use this property to install a heating system that will melt snow and ice in the winter.

- Great weight. The weight of a copper roof can be over a ton, even with a small cottage with an area of 100 m².

The use of non-ferrous metal can be considered a profitable investment, provided that the estimated service life of the building is 50 years or more.

Features of the installation of a copper roof

The installation of a seam copper roof begins with measures that are standard for all types of roofing. On the basis of the existing project, a rafter system is made, if necessary, a heater is inserted into it. Then, on both sides, the frame is covered with a membrane film. The next step is to install the counter battens and battens. Fastening of copper is carried out from the bottom up when working with tiles and from the center to the sides when building a standing seam roof. The seaming machine creates a sufficiently tight lock, but it is advisable to additionally seal it with a sealant, since the joint can weaken under constant temperature changes.