The decision to make an interior door with your own hands is promising in several directions. Firstly, it is a great opportunity to save money, as the added cost, shipping and installation costs account for most of the price of the finished product. Secondly, there is something to do in your free time, to realize your creative and artisan potential. This task cannot be called easy, but also impossible. It is necessary to think over the construction project well, choose materials, carefully and competently assemble.

Varieties of interior doors

The range of products presented in furniture stores is unlimited in size, configuration, design solution. It is not difficult to choose a product for your own interior, but the better it is, the more expensive it is. As a rule, canvases and boxes are made of wood. Iron doors in a private house and apartment are rarely installed.

Interior designs differ on several criteria.

By construction type:

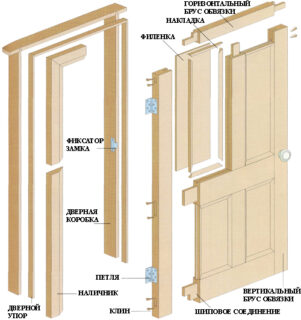

- Paneled. They have a rather complex device, representing a frame of lateral and horizontal elements (tsars), baguettes and panels. To fill the gaps, glass, plastic, pieces of plywood and chipboard covered with a film are used.

- Shield. The canvases are a rigid frame made of timber, on top of which canvases of fiberboard, plywood, MDF and plastic panels are fixed. The shield is made deaf or decorative glass is inserted into it.

- Massive (made of wood). Valuable species are used as raw materials, therefore, these products are characterized by high cost. The assembly is carried out from thick planks with a tongue-and-groove connection.

- Glass. The canvases are made of tempered or glued glass, they are distinguished by their presentable appearance, practicality and high weight, which places high demands on the strength of canopies.

- Swing. There can be one or two leaves, fastening is carried out on hinges located along the inner edges of the box. Tightness is achieved by installing seals. The swing design is simple and reliable, but it takes a lot of free space to open it completely. Latches, latches, latches and locks can be inserted into the frame.

- Sliding. They are canvases that move along a roller system parallel to the walls. The leaves are made blind or with transparent elements, lower, upper or combined guides. The advantage of such structures is their compactness, however, you will have to fork out well and come to terms with the lack of tightness.

- Folding (accordion). Depending on the size of the opening, they are made one- or two-sided. Consist of vertical slats connected by hinges. When assembled, they are located parallel to each other, protruding into the passage by 15-25 cm.

- Swinging. They represent a shield rotating on a vertical axis located in its center. The condition for the installation of such structures is a large opening width, where one half of it is sufficient for free passage. As a rule, swinging systems are mounted in passable places where rest and solitude are not expected.

The choice of interior doors for an apartment, a summer residence and a private house is determined by evaluating criteria such as style, design, attractiveness, reliability and applicability to specific conditions.

A set of necessary tools

To make solid and presentable interior doors with your own hands, you need the following devices:

- hand cutter;

- grinder machine;

- hand-held circular saw;

- electric drill;

- level;

- paint brush;

- roulette;

- square;

- chisels;

- a hammer;

- mallet;

- screwdrivers.

To protect your own health, work should be carried out in goggles and gloves, and when using paints and varnishes - in a respirator.

- Planed board 40x100 mm for frame assembly. A standard blade requires 600 cm of lumber.

- Beam 40x40 mm for creating stiffeners. You need to put 2-3 crossbars.

- 2 sheets of MDF. It is advisable to purchase laminated boards. This coating looks great, protects the sheets from moisture, dirt and mechanical damage.

- Internal filler. Depending on the available assortment of building stores, mineral wool, corrugated cardboard or expanded polystyrene (preferably extruded) are purchased.

- Hardware for door assembly. You cannot do without hinges, screws, washers, nails without hats.

- If the box needs to be upgraded, at least 12 anchor bolts are required. In addition, you will need putty and paint to seal the slope.

- Doorhandle. The choice of its design is made based on the purpose of the premises between which the door is to be installed.

You need to take care of the purchase of technical fluids. The finished product will be strong and durable if it is treated with an antiseptic, impregnation, varnish or paint. You can't do without wood glue.

Calculating door dimensions

Dimensions of doors and frames are regulated by GOST 6629-88. Based on the requirements of this act, the project documentation is being coordinated during private construction. If the repair is carried out in multi-storey buildings, standard openings are made in them.

In order not to carry out unnecessary measurements and calculations, you can use a ready-made table, where the data is indicated in millimeters:

| Web width | 600 | 700 | 800 | 900 | 1100 | 2×600 | 2×700 | 2×900 |

| Box width | 670 | 770 | 870 | 970 | 1172 | 1272 | 1472 | 1872 |

| Blade height | 2000 | 2300 | ||||||

| Box height | 2071 | 2371 |

Other indicators will only be if the decision is made to expand or narrow the opening. But here, too, the traced calculation method can be taken as a basis.

If planning is carried out independently, the dimensions of the opening should be determined in proportion to the area and configuration of the room. For narrow corridors, a wall-to-wall passage is equipped.

Making an interior door with your own hands

Initially, you need to decide on the door frame. If it is not skewed, the surface is clean and there are no signs of rot, it is advisable to leave it. It is much easier, simpler and faster to remove the old paintwork and apply a new one than to engage in long destructive and expensive installation work. It is better to restore the frame before assembling and hanging the canvas, when there is maximum access to the opening.

Step-by-step instructions for making an interior door:

- Carry out measurements, execute a detailed drawing. In order not to confuse anything, it is advisable to draw up a step-by-step plan for the implementation of all the planned actions.

- Purchase material and missing tools. The wood must be free of stains, dents, chips and knots. The admissible humidity level is 17-25%. It is better to take pine, as it optimally combines criteria such as weight, strength and price. If necessary, the boards are dried or pick up the missing moisture in the room.

- Assemble the frame of the canvas. It is made from horizontal and vertical profiles. The connection is carried out in the grooves with the addition of wood glue for strength and volume. Along the way, grooves for the panels are selected in the frame with a cutter, if this type of sash is selected.

- Fold the canvas into a single structure. There are two ways here.If the panel type is selected, the sheets or boards are fastened, first from one side, and then from the other side. At the same time, the insulation is loaded into the opening. Soft slabs are placed on the floor, and hard ones are fixed at the edges with polyurethane foam. Panels and slabs are fixed in grooves that are adjusted to their dimensions. Internal parts are made of boards, chipboard or OSB. An excellent solution is to use honeycomb or monolithic polycarbonate in transparent, colored or matte finish.

In conclusion, you need to check the assembled product for strength and correct geometry. Remove minor imperfections by grinding or gluing thin pieces of wood or sealant.

The finished canvas must be properly hung in the opening. The grooves for the hinges are cut with a hand cutter, after which they are adjusted to the optimal position and screwed in with self-tapping screws. Hats and hinges can be covered with putty. Then a handle with a latch and a counterpart are placed. A drill and chisels are used here.

When everything is set up and fitted, it's time to spend the finishing touches. Wood can be painted, varnished or stained. If applicable to the style and interior of the room, overlays are made of plastic, non-woven wallpaper, leather, fabric or painted panels.

Finally, grease the metal movable joints - lock, handle, latch and hinges.