Different materials are used to insulate and decorate the exterior of the building. A wet facade is not a very new, but an effective solution that is becoming more and more popular. This design is capable of performing several functions at once, and for a long time.

What is a wet facade

Correct finishing of the facade allows you to preserve its decorative attractiveness and protect the base from the negative influence of external factors, to reduce heat loss. A wet finish system is considered to be more efficient and attractive, and is also less expensive than dry construction.

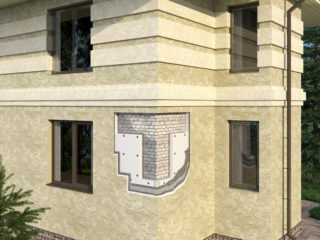

The peculiarity of the facade is a large number of layers. Each of them has its own meaning: it isolates, protects, adds decorative effect. In order for the structure to perform its functions as well as possible, high quality materials are used.

Wet facade technology involves the use of water-based adhesives to fix the elements together. All work must be done in a strictly specified order.

Before proceeding with the arrangement of the structure, you need to consider what layers it consists of:

- Base. It can be made from brick or concrete. The main requirement for it: the minimum number of curvatures and defects. If they are present, a leveling plastering of the base is carried out before the installation of the facade.

- Heat insulator. It is fixed with a special adhesive.

- Reinforcing layer. use a fiberglass mesh, which is recessed into a layer of adhesive solution.

- Finishing finish.

Plaster, paint or lightweight facade panels are often used as cladding.

Materials for a wet facade

- Glue. It is better to use a mineral-based composition that additionally contains polymer components.

- Basement profile. The most suitable option for a wet facade is aluminum. A perforated product is considered to be of the highest quality. Due to this, moisture does not penetrate into the structure and does not remain there. When choosing, take into account the thickness and size of the insulation plates.

- Start profile. This element is mounted to hold the insulating material in place.

- Reinforcing mesh. Fiberglass material is usually taken. If the load is too heavy, the mesh may be metal.

Wet facade plaster provides for the application of a finishing decorative layer.

Quality criteria

Before doing the installation of a wet facade, you need to consider the criteria for its quality. They determine the duration of operation and the effectiveness of the structure. When choosing, they pay attention to the following factors:

- building design features (miscalculations are made in advance);

- weather conditions acceptable for work;

- availability of the necessary tools and materials;

- the qualification level of the master (if the work will not be performed independently).

To produce a high-quality façade, full adherence to the assembly instructions is required. After the arrangement, the structure will need to be periodically inspected for damage or defects.

Building preparation

The front surface must be prepared. All work is carried out in the warm season. If there is a chance of precipitation, the installation area is covered with polyethylene.

All rooms must be closed. It is better to carry out the work after installing the roof. It is also recommended to complete the internal renovation work. The outer surface of the wall is cleaned of debris, sagging, dust. At this stage, fasteners for the drainage system, air conditioner are fixed.

In the process of preparation, the master examines the base for its strength, since the facade structure has a certain weight. To fix the insulation, glue is most often used, so the surface must have good adhesion.

Exfoliating areas are eliminated. The cleaned areas are rinsed under pressure, after which they are allowed to dry completely. The base is leveled with a putty. The level change does not exceed 1 cm / m². All materials must have good compatibility with each other. If the walls are even, only chips and cracks are covered with putty.

When using porous materials for the construction of a building, the base is treated with a deep penetration primer. It improves adhesion, but also reduces glue consumption. Old finishing materials are removed from door and window openings.

DIY manufacturing technology

Installation of a wet facade is not a simple procedure. The job requires patience and precision. It includes the following stages:

- Preparatory. Installation of a plinth profile is required. It is fixed at a distance of 35-40 cm from the ground. Gaps of 0.5-1 cm are provided between the elements. This is necessary to compensate for thermal expansion. Self-tapping screws are used for fastening, the distance between which is 15 cm.

- Heat insulating. Insulation of the facade is carried out in a strict sequence. First, the glue is distributed along the perimeter of the material, stepping back from the edges of 3 cm. In the center of the plates, the substance is applied pointwise. Glue should cover at least 40% of the area of the insulation. The slabs are laid according to the brickwork principle. The elements should be pressed against each other as tightly as possible. It is required to start laying from the bottom up. It takes 3-4 days for the glue to dry completely. For additional fixing of the plates, dowels are used.

- Reinforcement. A metal or fiberglass mesh is used to strengthen the facade. It is fixed with an adhesive composition 2-3 days after the installation of the insulation. The first pieces of material are attached to corners, window and door openings. The mesh must be sunk into a layer of glue. The excess pieces are cut off.

The last step is decorative plastering of the surface. This layer ensures the attractiveness of the building and reliable protection of the insulation from atmospheric agents. The plaster is applied only after the reinforcing layer has completely dried - after 7 days. The advantage of this material is that it allows air to pass through, ensuring optimal moisture exchange.

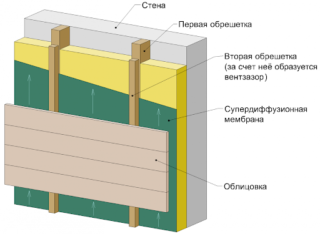

Comparison of a wet facade with a ventilated one

The design of a ventilated and wet facade is somewhat different. The second option is characterized by the fastening of the insulation with glue with additional fixation with dowels. In addition, there is a reinforcing and decorative layer. All parts of the structure are assembled in a predetermined sequence right at the construction site. The advantage of such a facade is the increased resistance to fire, since the glue and plaster reliably protect the insulation. The mass of the structure is small, so it is installed even on those houses that stand on soft ground.Installation technology is not difficult.

The ventilated façade is also an external structure that is attached to the wall with guides and brackets. In this case, adhesives are not used. After fixing the insulation, a layer of vapor-permeable film is laid. It will protect the insulation from the wind. Further, horizontal and vertical profiles are installed, to which decorative panels made of porcelain stoneware, galvanized metal, refractory plastic or fiber cement are equated.

The ventilated facade differs in that there is a gap of 2-3 cm between the finishing and the thermal insulation. The stages of work do not involve the use of water.